Multi-section anchoring energy dissipation yielding anchor rod for rockburst and anchoring method

A technology for pressure bolts and rock bursts, applied in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problems of anchoring, pulling out and breaking, reducing deformation damage, inhibiting cracking, improving The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

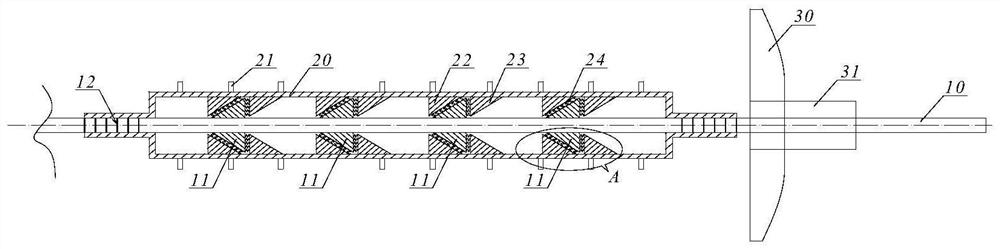

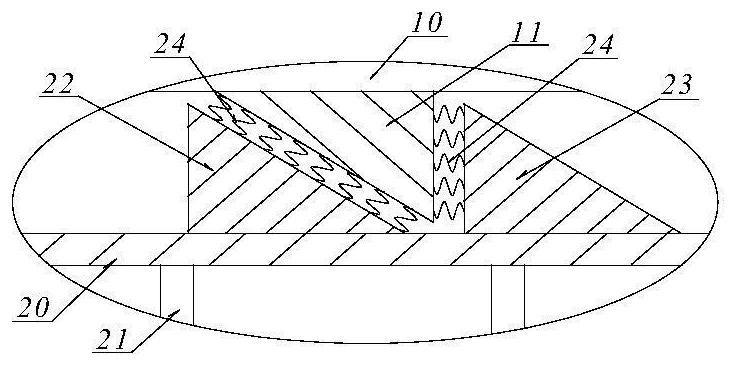

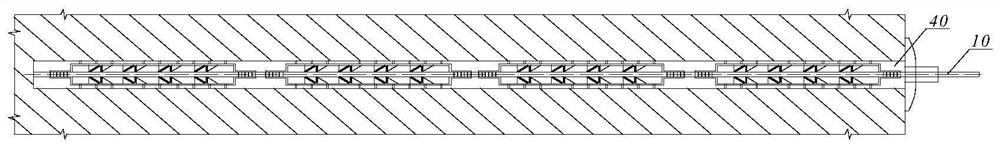

[0022] refer to figure 1 and image 3 According to the present invention, a multi-stage anchoring energy-dissipating anchor rod for rockbursts of the present invention includes a rod body 10 passing through a stress relief hole 40 and a tray 30 and a lock nut 31 located outside the stress relief hole 40 . The rod body 10 is fitted with at least two longitudinally spaced compression sleeves 20, the compression sleeves 20 are tightly fixed on the rod body 10 through the rubber rings 12 at both ends, and the outer walls of the compression sleeves 20 are vertically spaced. The ring-shaped toothed cutter 21 is welded to it, and the outer diameter of the ring-shaped toothed cutter 21 is adapted to the diameter of the stress release hole 40 . refer to image 3 , in the process of specific support, the multi-stage anchoring consumption can allow the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com