Fairing and pressure reducing valve

A technology of fairing and pressure reducing valve, which is applied in the direction of balance valve, valve device, valve details, etc., can solve the problems affecting the health of the staff, the technical water supply flow of the unit is large, and the operation noise is large, so as to improve the effect of voltage stabilization, Effect of reducing fluid noise and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

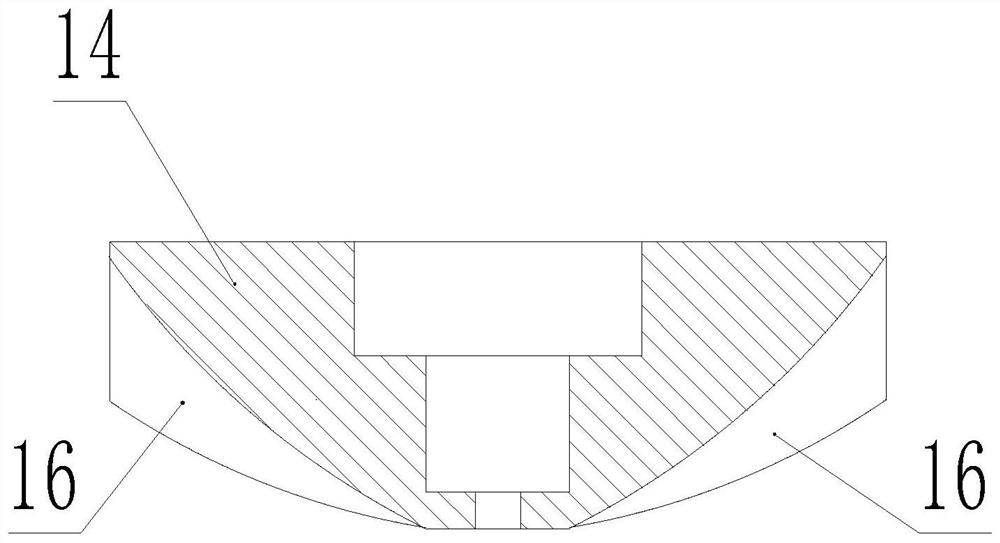

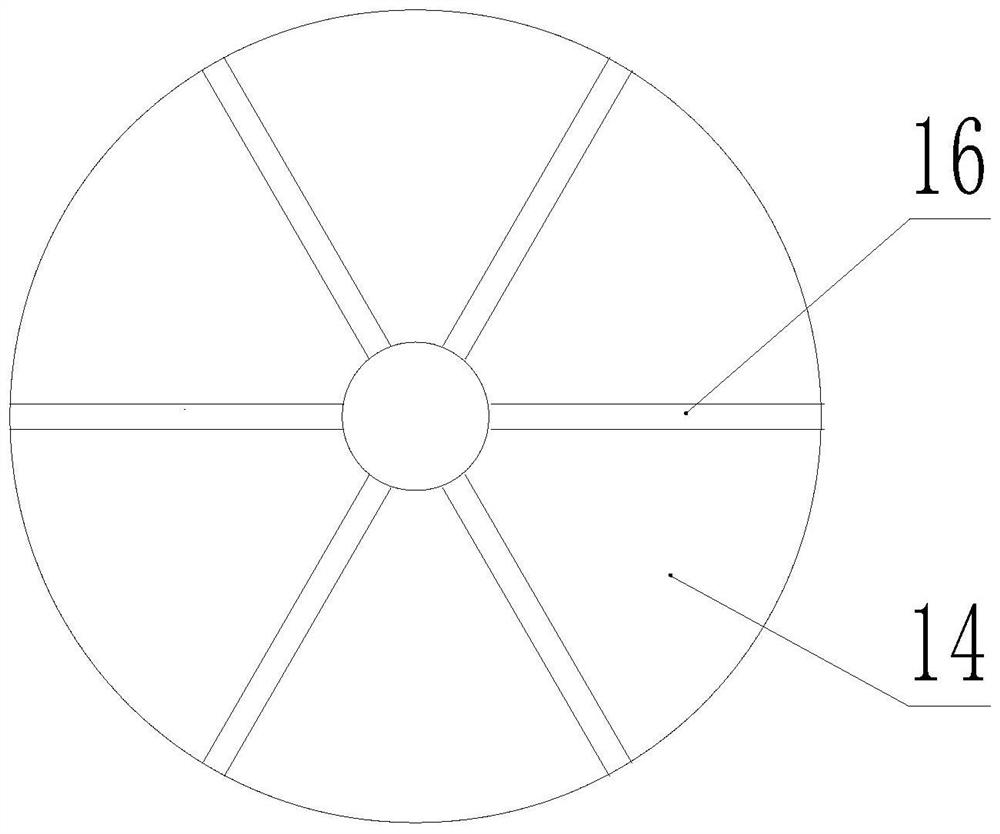

[0027] like figure 1 and figure 2 A kind of fairing shown, comprises the cover body 14 that is conical shape, and the outside wall of cover body 14 is the conical surface that diameter is big up and down is small, and the outside wall of cover body 14 is the curved surface that protrudes outwards, and cover body 14 A plurality of splitter plates 16 are connected on the outer side wall of the cover body 14, and the plurality of splitter plates 16 are arranged at intervals along the circumferential direction of the cover body 14, and the plurality of splitter plates 16 are arranged perpendicular to the circumferential direction of the cover body 14.

[0028] In this embodiment, a plurality of splitter plates 16 are arranged at equal intervals along the circumferential direction of the cover body 14 .

[0029] In this embodiment, the upper edge of the splitter plate 16 is connected to the outer side wall of the cover body 14 , and the lower edge of the splitter plate 16 is a cu...

Embodiment 2

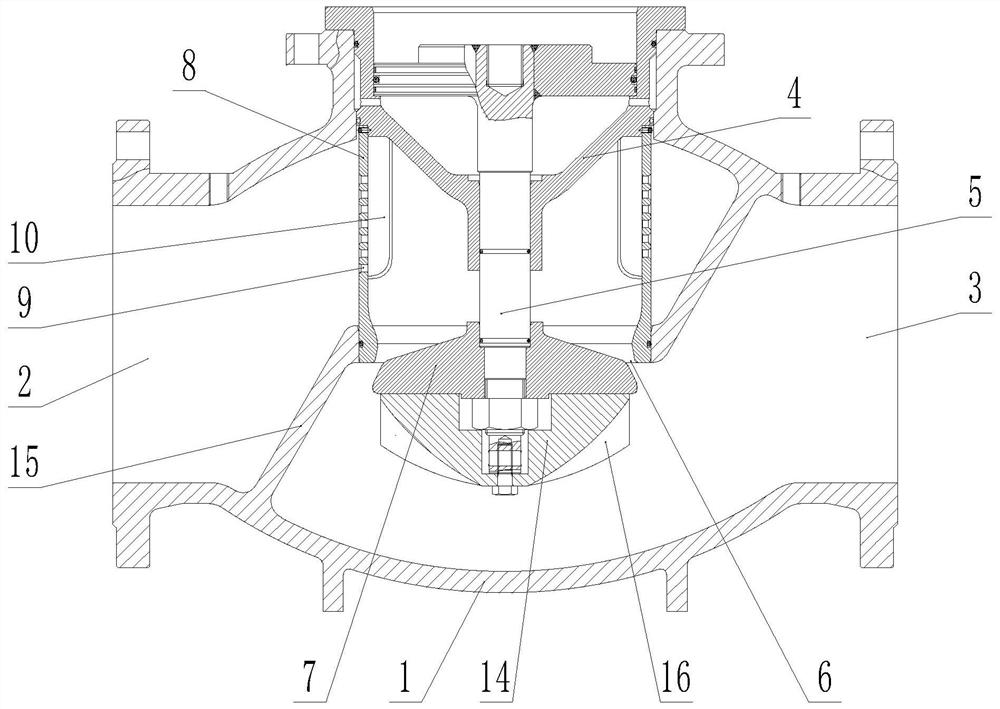

[0033] like Figure 3 to Figure 5 The pressure reducing valve shown includes a valve body 1 provided with a medium inlet channel 2 and a medium outflow channel 3. A partition 15 is provided inside the valve body 1, and a communication medium inlet channel 2 and a medium outflow channel are provided on the partition 15. The valve port 6 of the channel 3, the valve body 1 is also provided with a valve stem 5 and a throttling cone 7 installed on the lower end of the valve stem 5. The throttling cone 7 can adjust the opening of the valve port 6. The upper end of the valve stem 5 is usually There is a piston matched with the cylinder liner 4, the lower side of the throttle cone 7 is connected with the fairing described in the first embodiment, the lower end of the valve stem 5 passes through the throttle cone 7 and the fairing, and the valve stem 5 is provided with Pressing down against the step surface of the throttle cone 7, a nut is connected to the lower end of the valve stem 5...

Embodiment 3

[0042] like Image 6 and Figure 7 In the pressure reducing valve shown, the difference between the noise reduction sleeve 8 in this embodiment and the noise reduction sleeve 8 described in Embodiment 1 lies in the arrangement of multiple guide parts. In this embodiment, A plurality of deflectors constitute a plurality of second deflectors 11 extending in the vertical direction and a plurality of third deflectors 12 extending in the vertical direction, and each second deflector 11 is composed of at least two deflectors. connected sequentially, multiple second deflectors 11 are arranged at intervals along the circumference of the noise reduction sleeve 8, each third deflector 12 is formed by connecting at least two deflectors in sequence, and multiple third deflectors The deflectors 12 are arranged at intervals along the circumference of the noise reduction sleeve 8, and the plurality of second deflectors 11 are located on the upper side of the plurality of third deflectors 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com