An adaptive installation mechanism and door structure for flexible variable pressure pipelines

A technology of installation mechanism and variable pressure, which is applied in the direction of pipeline support, household refrigeration device, application, etc., can solve the problem that the space of vehicle cooling device cannot be fully utilized, and achieve the effect of avoiding frictional stretching damage, preventing vibration and distortion deformation

Active Publication Date: 2022-05-31

HEFEI GENERAL MACHINERY RES INST

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to solve the major defect that the space of the vehicle-mounted cooling device in the prior art cannot be fully utilized, the present invention proposes a flexible connection technology for Freon pipelines: that is, an adaptive installation mechanism and door structure for flexible variable pressure pipelines, Using this mechanism, an air-cooled heat exchanger can be arranged on the inspection door of the cooling device to increase the heat dissipation capacity of the cooling device and at the same time ensure the normal opening and closing of the inspection door and other inspection functions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

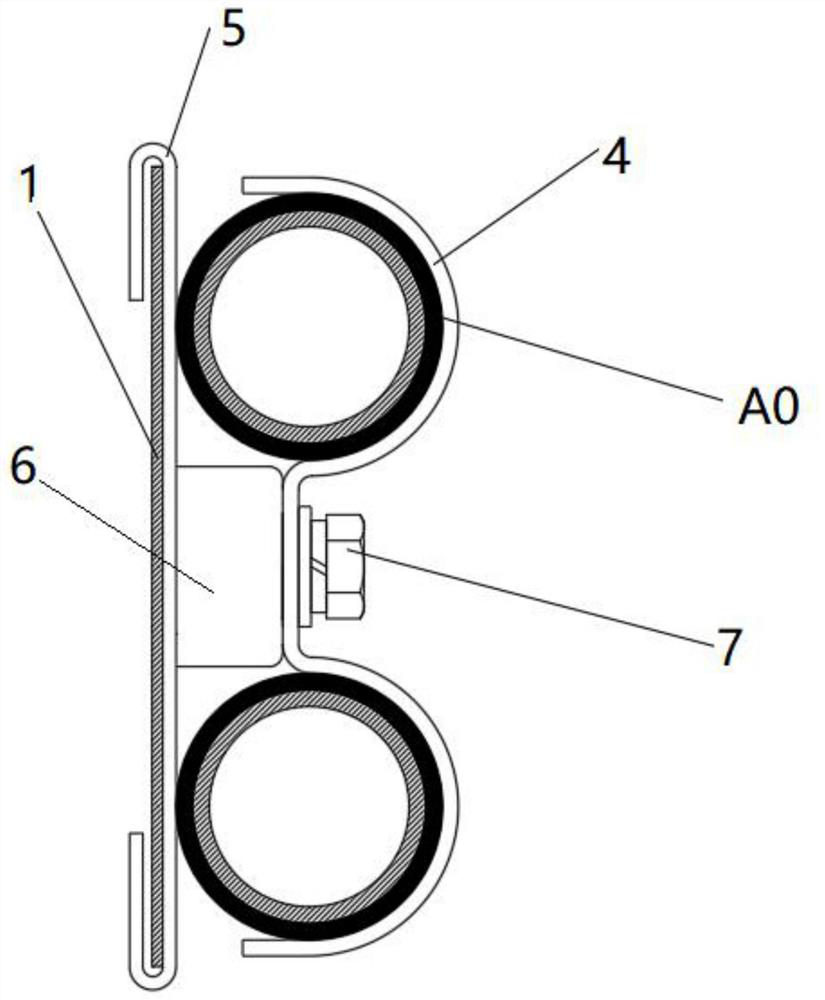

[0049] Thus, in this embodiment, the constraining unit is slidable on the fixed plate 1, and the pipeline is installed by the constraining unit,

[0050] In this embodiment, the sliding plate member 5 is sleeved on the fixed plate 1. In specific implementation, the guide grooves and guide protrusions can also be used.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

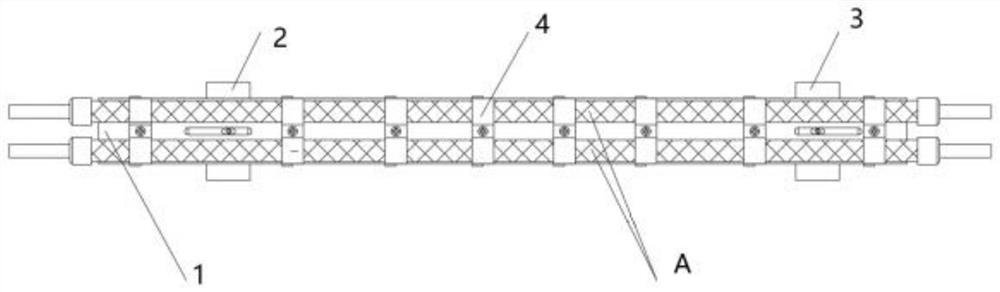

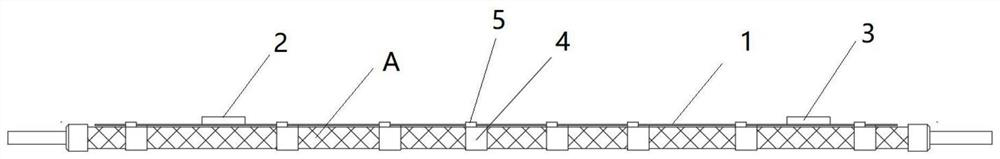

Login to View More Abstract

An adaptive installation mechanism for flexible variable pressure pipelines, comprising: a bendable fixing plate, a first fixing block, a second fixing block and a plurality of constraining units; the first fixing block and the second fixing block are respectively connected with the fixed The plates are slidingly connected, and the first fixed block and the second fixed block are located on the same side of the fixed plate; the sliding direction of the fixed plate relative to the first fixed block is on the same line as the sliding direction of the fixed plate relative to the second fixed block A plurality of constraint units are installed on the fixed plate, and a positioning hole for clamping the pipeline is formed between each constraint unit and the fixed plate, and the positioning hole is located on a side of the fixed plate that is away from the first fixed block and the second fixed block side. In the present invention, restraint and support are provided for the bendable pipeline through the constraining unit and the fixing plate, and the bending is ensured through the sliding setting of the fixing plate relative to the first fixing block and the second fixing and the sliding setting of the restraining unit relative to the fixing plate The normal release of the pipe expansion and contraction amount.

Description

An Adaptive Mounting Mechanism and Door Structure for Bendable Variable Pressure Pipes technical field The present invention relates to pipeline installation structure technical field, relate in particular to a kind of self-adaptive for flexible variable pressure pipeline Mechanism and door structure shall be installed. Background technique With the increasing heat dissipation of vehicle-mounted radar equipment, the cooling device of vehicle-mounted radar equipment (hereinafter referred to as "vehicle cooling") The cooling capacity of the "device") is also increasing. Due to the limited installation space, the on-board cooling device must meet the heat dissipation requirements of the radar equipment. Its limited equipment space must be fully utilized. The air-cooled heat exchanger of the vehicle-mounted cooling device occupies a large space, and its arrangement space determines the cooling device to a certain extent. cooling capacity. In order to have good maintai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F25D11/00F25D23/00F25D23/02F25D23/06H05K7/20F16L3/10F16L3/18F16L55/035

CPCF25D11/00F25D23/00F25D23/02F25D23/06F16L3/10F16L3/18F16L55/035H05K7/20136H05K7/20145

Inventor 钟根仔侯春枝陈恩丁东旭刘浩

Owner HEFEI GENERAL MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com