Heating furnace door device with stable and rapid opening and closing functions

A heating furnace and furnace door technology, applied in the field of machinery, can solve the problems of large force load, large connecting rod load, inability to adjust, etc., and achieve the effect of ensuring the degree of closing, ensuring the heat preservation effect, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

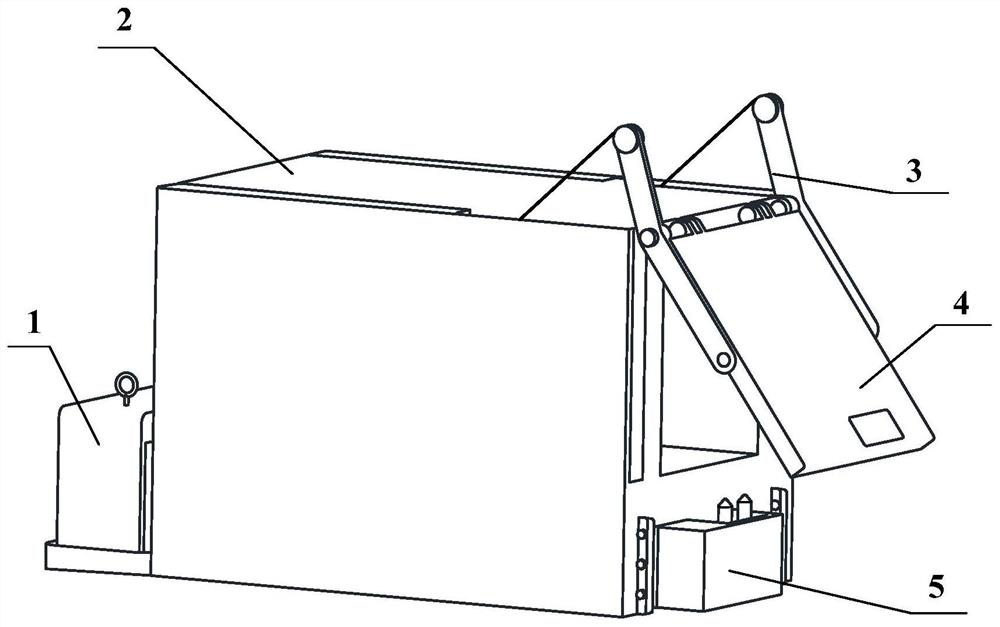

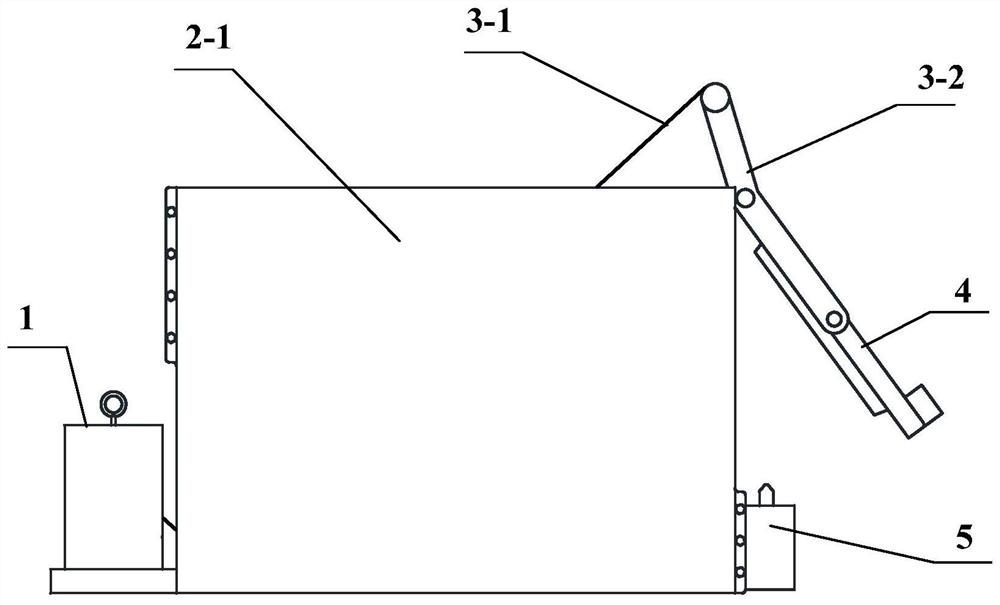

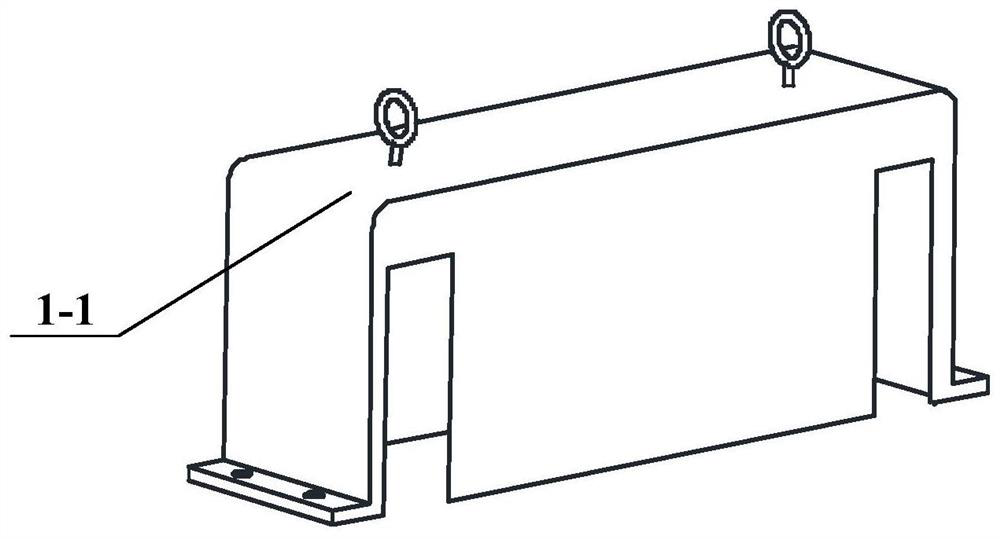

[0043] see figure 1 , figure 2 , a heating furnace door device with stable and fast opening and closing functions, including a main power system 1, a furnace body 2, a power transmission system 3, a furnace door 4, and an automatic door locking system 5; the main power system 1 passes through Bolts are installed on the rear base of the furnace body 2; the power transmission system 3 is installed on the left and right sides of the furnace body 2 through bolts; the bottom of the furnace door 4 is installed on the front end of the furnace body 2 through hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com