Condenser performance online monitoring and analyzing method and computer expert system

A condenser and performance technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of poor intuition, analysis system and data huge, missing, etc., and achieve the effect of accurate understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

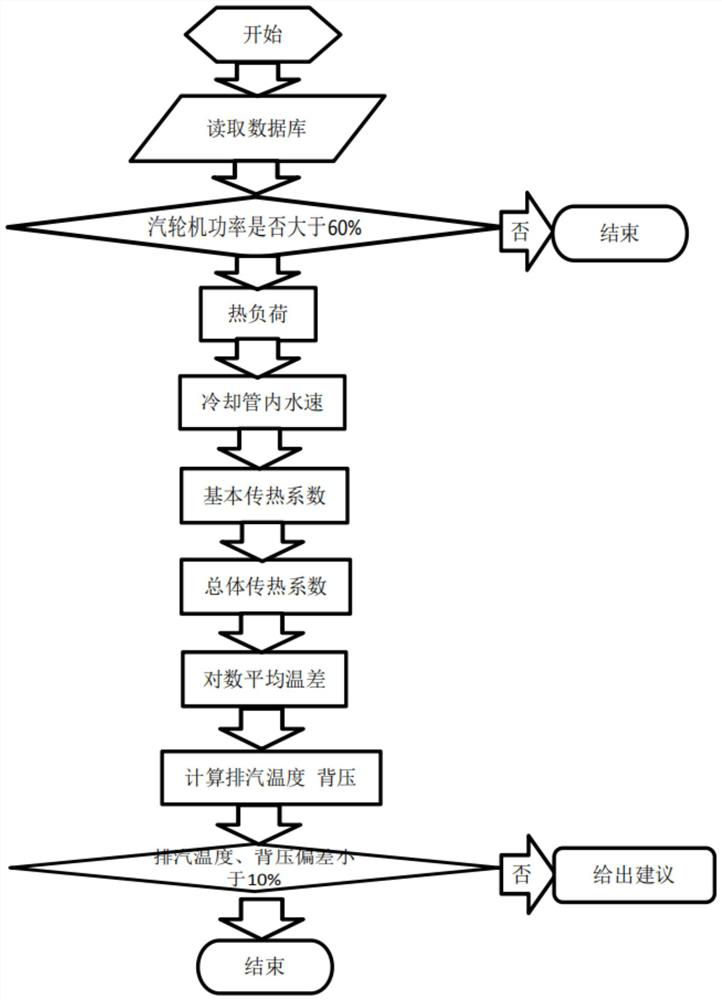

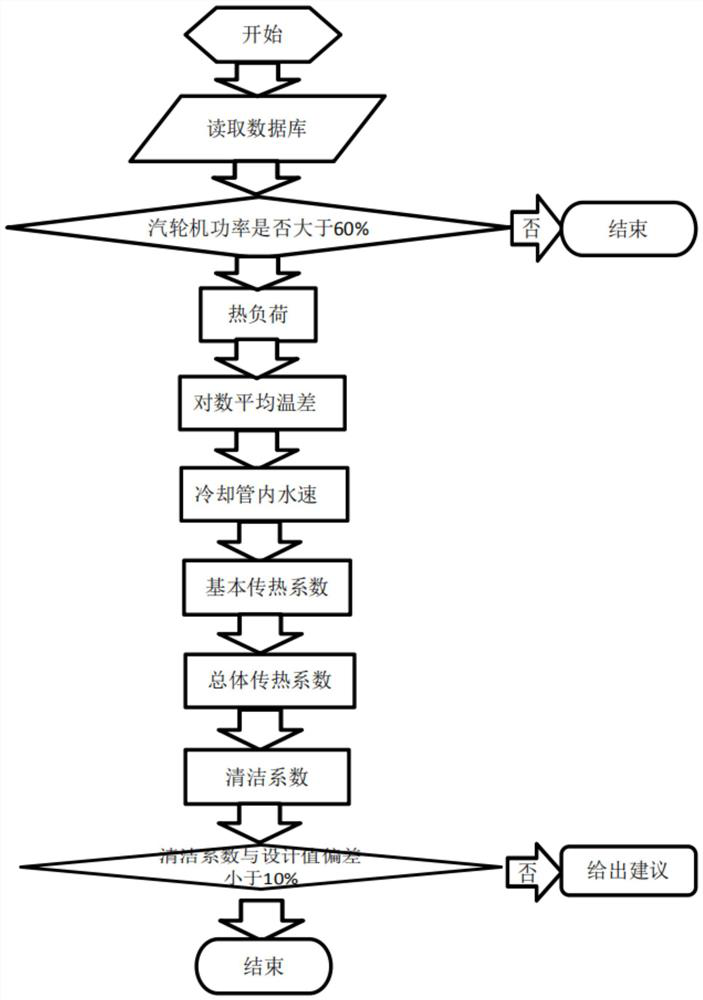

[0067] In this embodiment, a method for on-line monitoring and analysis of condenser performance is specifically provided, the method comprising:

[0068] S1: Real-time collection and storage of operation data of condenser measuring points, steam turbine measuring points and auxiliary equipment measuring points in the database; among them, condenser measuring points, steam turbine measuring points and auxiliary equipment measuring points are the existing measuring points of the power plant , through the DCS system of the power plant to realize data collection and transmission to the database.

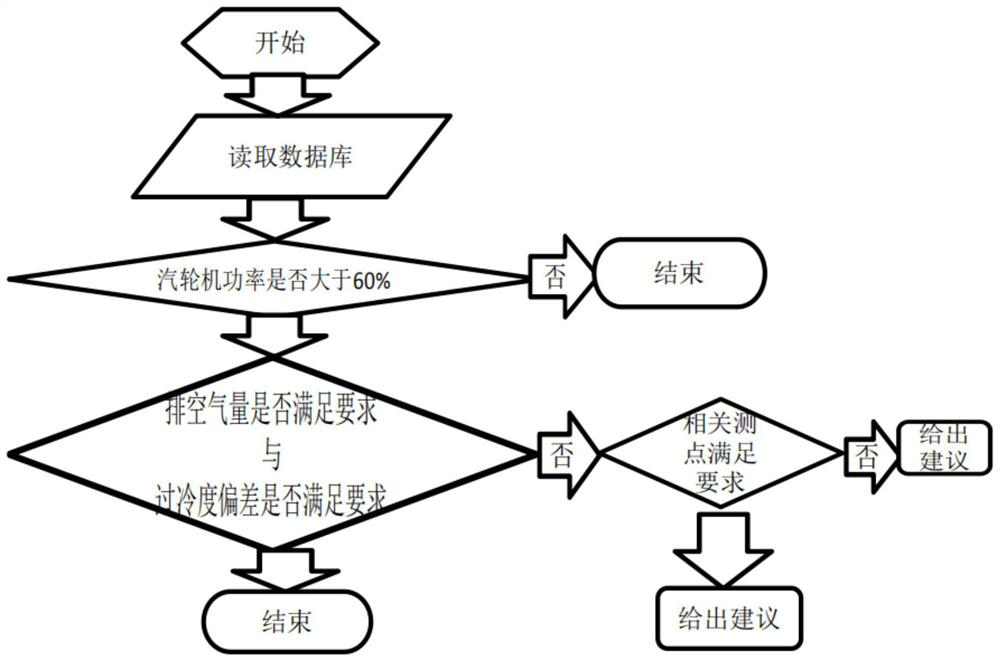

[0069] S2: Read the database data and judge whether the current steam turbine power is greater than 60%. If it is satisfied, enter the condenser operation index acquisition; The plant allows long-term operation of the turbine power setting.

[0070] S3: Judging whether the operation index of the condenser meets the requirements, if it is satisfied, then end; if not, give a suggestion; ...

Embodiment 2

[0118] Also provided in the present invention is a computer expert system for on-line monitoring and analysis of condenser performance, the system is based on the method for on-line monitoring and analysis of condenser performance described in the above-mentioned embodiment 1, the system includes:

[0119] The sensors that are respectively arranged at each condenser measuring point, steam turbine measuring point and auxiliary equipment measuring point, the data that each sensor needs to measure is as described in Embodiment 1, and the installation position of each measuring point is set with reference to the power plant standard, here I won't repeat them here.

[0120] A data memory connected to each of the sensors in communication, the data memory receives and stores the measurement data of each sensor in real time, and relevant data of the HEI standard is also stored in the data memory.

[0121] The computing host computer connected with the data memory communicates, reads t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com