Cement bin material level height detection device

A technology of material level height and detection device, which is applied in the direction of measuring device, lubrication indicator device, liquid/fluid solid measurement, etc., can solve the problems of poor anti-interference ability of sound waves, great influence of sound waves, low frequency, etc., to reach the material level Good simulation, stable echo data, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0036] Real-time and clear grasp of the status of the materials in the cement silo and the real-time monitoring of the material hanging on the wall of the silo are the goals that the cement industry has been pursuing. The invention realizes real-time monitoring of the material situation, serves for the arrangement of the production progress, and realizes safe production when workers clean the silo.

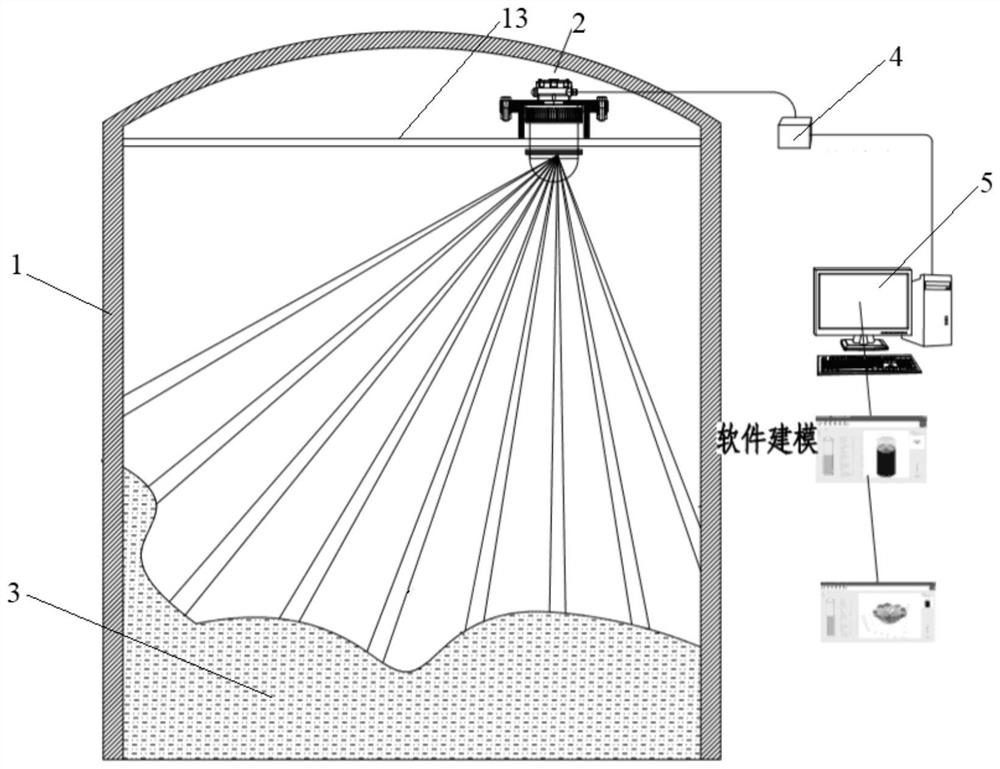

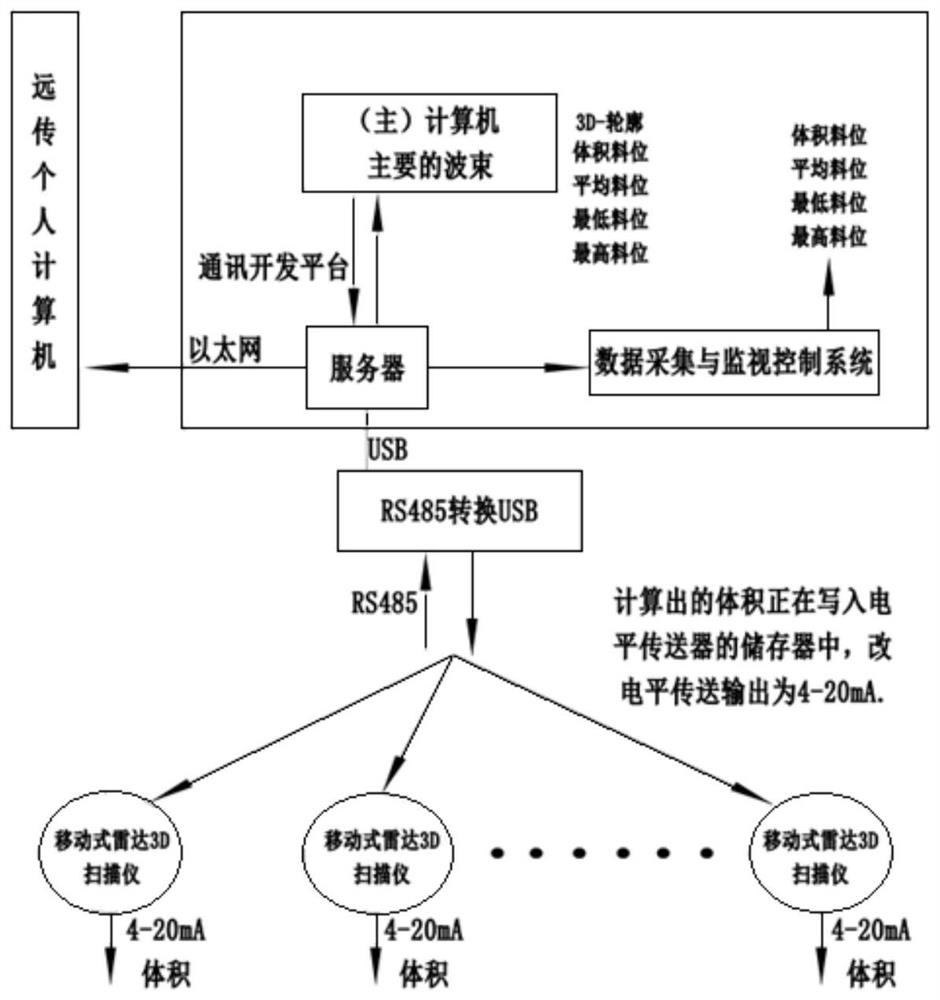

[0037] Such as figure 1 The structure of the present invention expressed is a cement silo material level height detection device, and the cement silo 1 stores solid materials 3 in the form of finely divided blocks, particles, or powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com