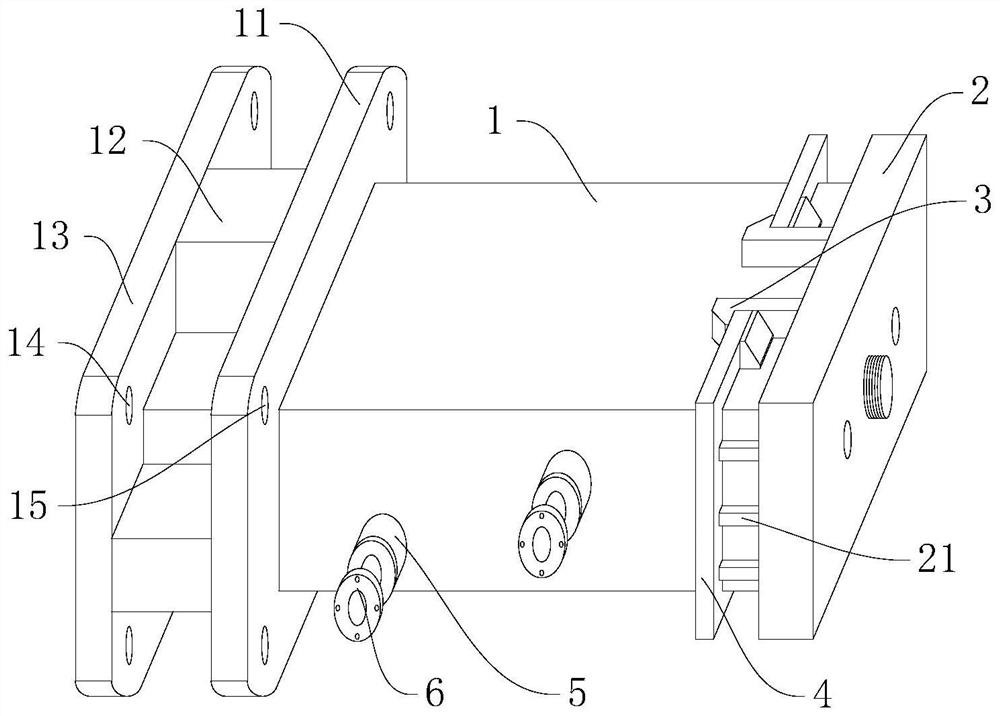

Waveguide short-size water load

A short-size, water-loaded technology, applied in the field of waveguide feeders, can solve the problems of large volume and weight, and lack of advantages in heat dissipation, and achieve the effects of increasing the scope of application, quick disassembly and assembly, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

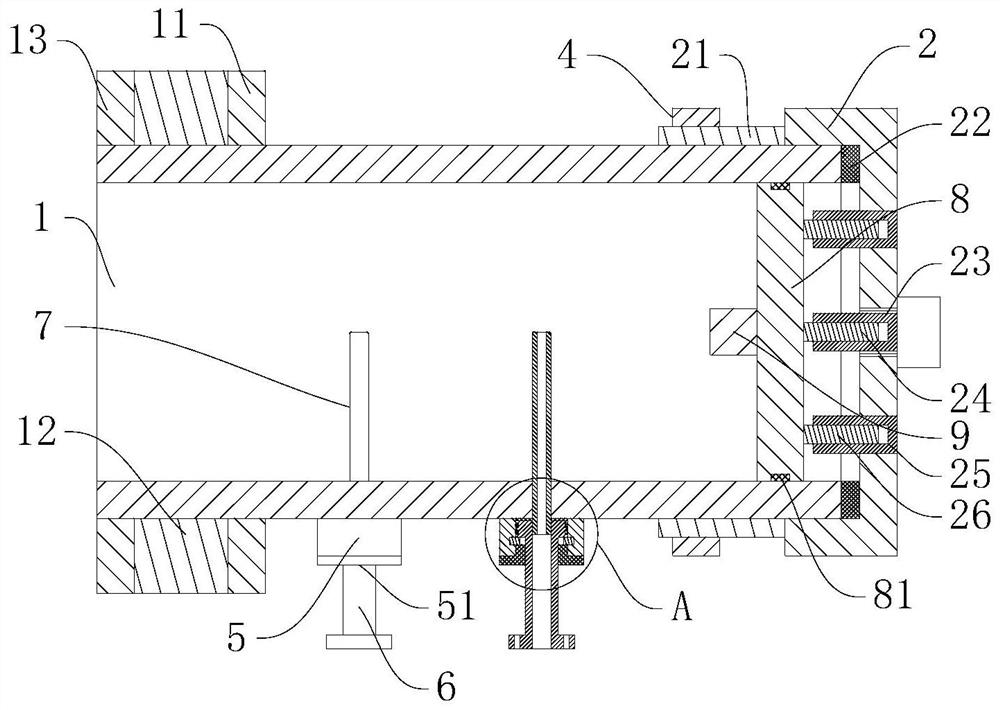

specific Embodiment approach

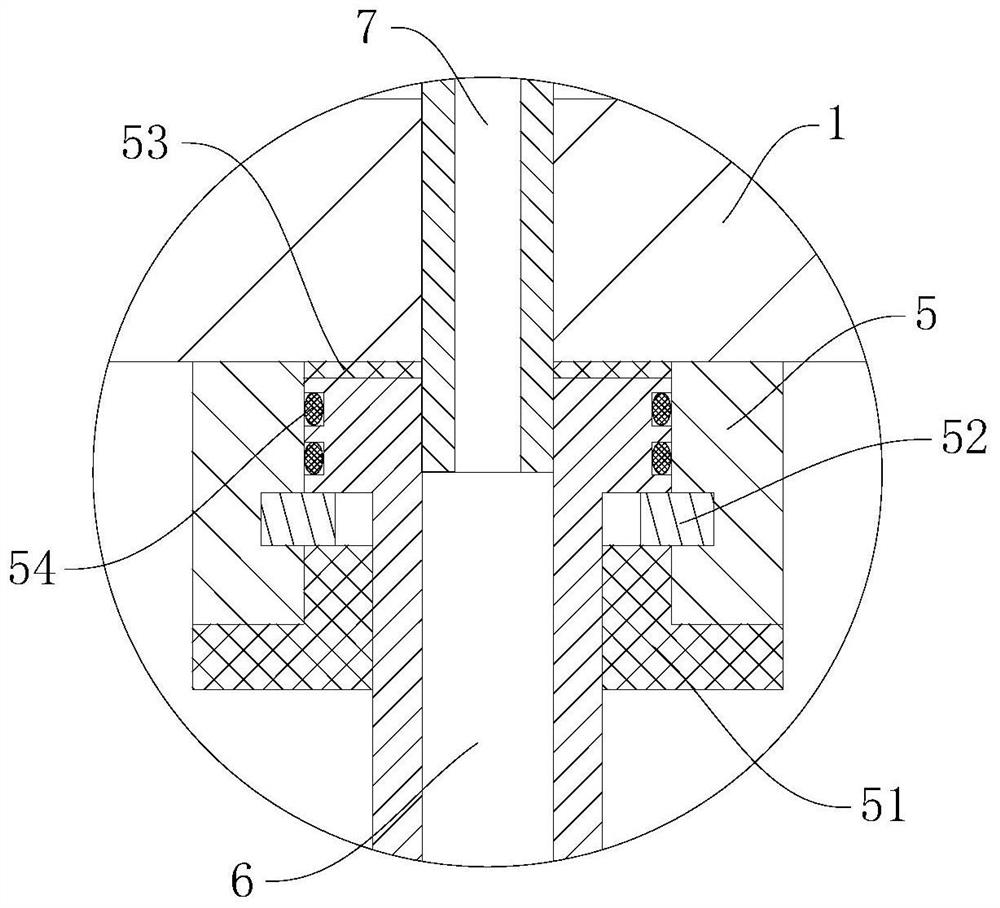

[0035] Specific implementation method: First, insert the dielectric material hollow post 7 into the rectangular waveguide cylinder 1, and insert the I-shaped inlet nozzle 6 into the outer cylinder 5, and then use tools to insert the retaining spring 52 into the outer cylinder 5 , and assembled to the inner annular slot of the outer cylinder 5, so that the I-shaped inlet water nozzle 6 is limitedly installed on the outer cylinder 5, and then the hollow insert 7 of the dielectric material is installed in the rectangular waveguide cylinder 1, and then the second can be rotated. A sleeve 23, because the first sleeve 23 is threadedly connected with the stud 24, so the rotation of the first sleeve 23 will make the stud 24 move left and right, and then drive the movable rectangular plate 8 to move along the inner wall of the rectangular waveguide 1 to suitable position, and then insert the movable rectangular plate 8 into the rectangular waveguide 1, so that the deployment column 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com