Chemical reaction kettle for solid-liquid reaction

A technology of chemical reaction and solid-liquid reaction, applied in chemical/physical/physical chemical fixed reactor, control/adjustment process, chemical instrument and method, etc., can solve the problem of reducing environmental protection of equipment, inconvenient recycling of water resources, etc. problems, to achieve the effect of improving environmental protection, avoiding blockage, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

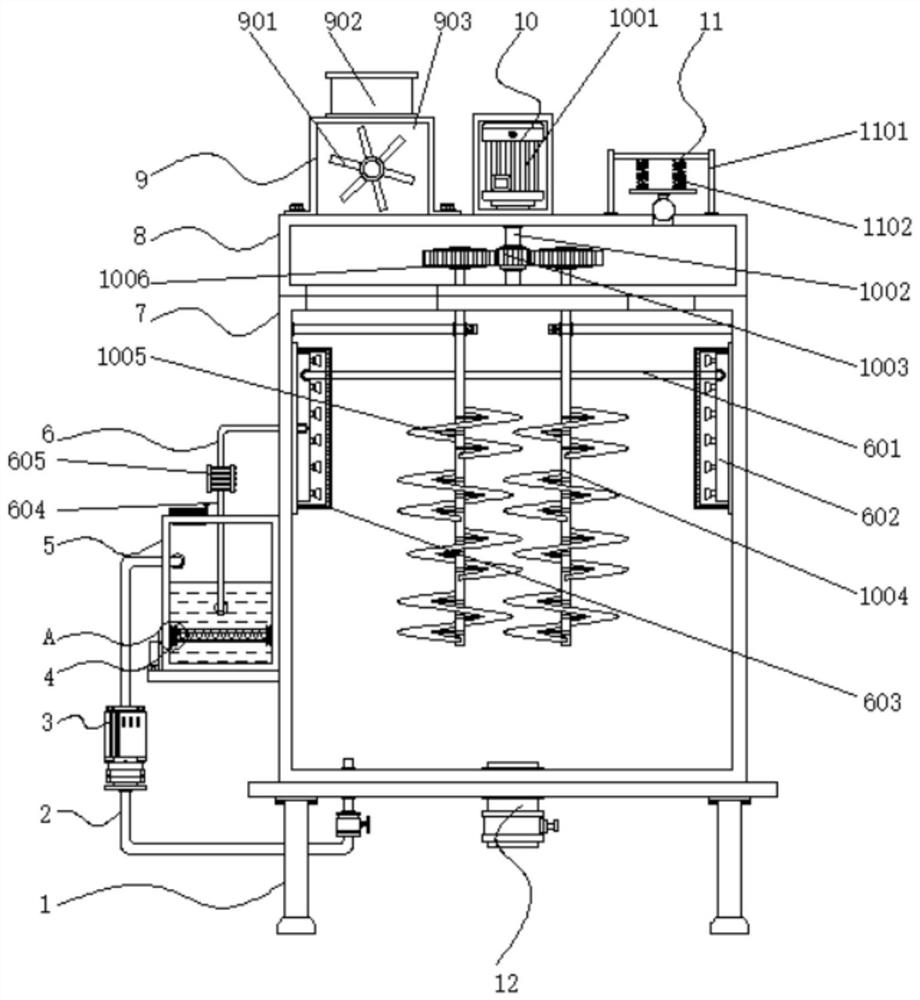

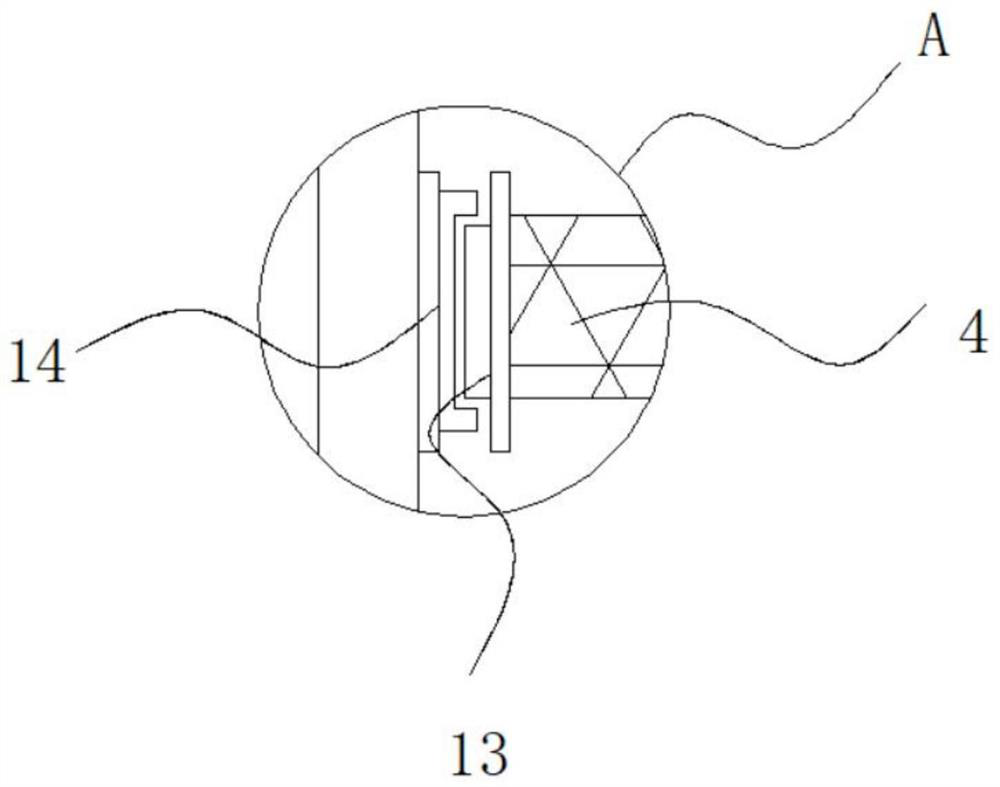

[0035] Example 1: See Figure 1-6, a chemical reaction kettle for solid-liquid reaction, comprising a kettle body 7, legs 1 are fixedly connected to both sides of the bottom end of the kettle body 7, a liquid outlet pipe 12 is fixedly connected to the middle position of the bottom end of the kettle body 7, and the bottom of the kettle body 7 One side is fixedly connected with a water tank 5, and the both sides of the kettle body 7 are provided with a spray mechanism 6, and the top of the kettle body 7 is fixedly connected with a connecting seat 8, and one side of the top of the connecting seat 8 is provided with a leveling mechanism 9, and the connecting seat The other side of the top of 8 is provided with a decompression structure 11, the middle position of the top of the connection seat 8 is provided with a stirring mechanism 10, and one side of the water tank 5 is provided with a recycling mechanism;

[0036] see Figure 1-6 A chemical reaction kettle for solid-liquid reac...

Embodiment 2

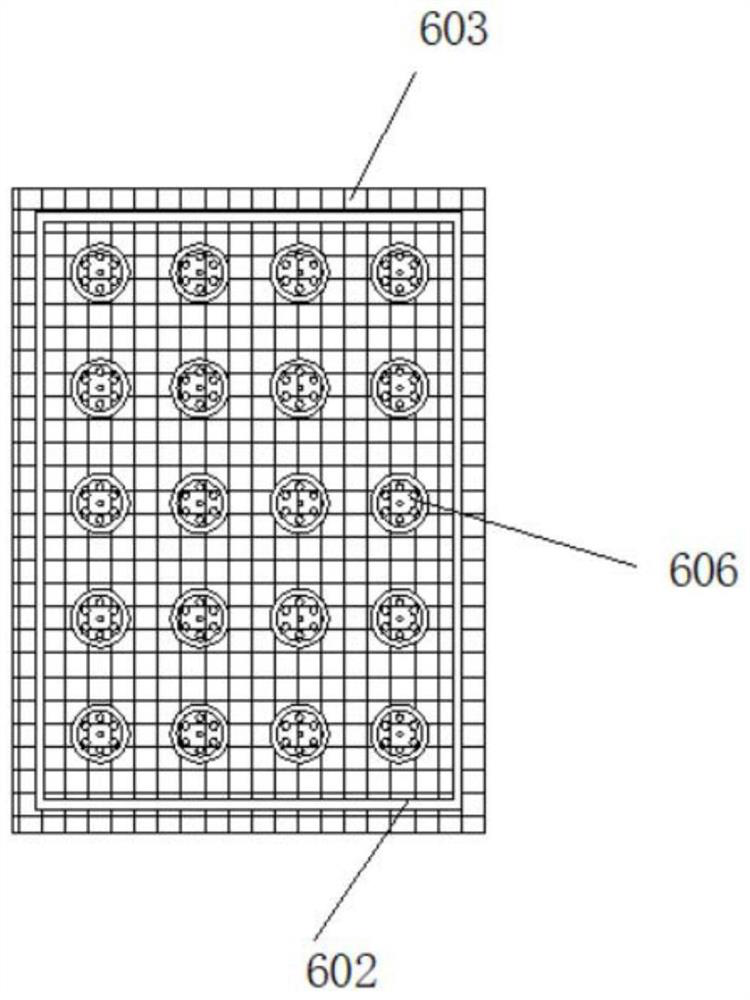

[0038] Embodiment 2: The spraying mechanism 6 is composed of a through pipe 601, a distribution pipe 602, a net cover 603, a water suction pipe 604, a water pump 605 and a spray nozzle 606. On both sides, the other side of the distribution pipe 602 is fixedly connected with a spray head 606, the outside of the distribution pipe 602 is provided with a net cover 603, the distribution pipe 602 is fixedly connected with a through pipe 601, and one side of the distribution pipe 602 is provided with a suction pipe 604, a water pump 605 is provided outside the top of the water suction pipe 604, the model of the water pump 605 can be QW, and the bottom end of the water suction pipe 604 runs through the inside of the water tank 5;

[0039] The lengths of the distribution pipes 602 are equal, and the distribution pipes 602 are symmetrically distributed about the vertical center line of the kettle body 7;

[0040] Specifically, such as figure 1 and figure 2 As shown, when the material...

Embodiment 3

[0041] Embodiment 3: The leveling mechanism 9 is composed of a leveling plate 901, a feed port 902, a fixed seat 903, a drive motor 904 and a first connecting shaft 905, the fixed seat 903 is fixedly connected to one side of the top of the connecting seat 8, and the fixed seat The top of the 903 is fixedly connected with a feed inlet 902, and the middle position inside the fixed seat 903 is fixedly connected with a first connection shaft 905, and the outside of the first connection shaft 905 is fixedly connected with multiple groups of screed plates 901, and the screed plate 901 The inner diameter is greater than the outer diameter of the first connecting shaft 905, and the uniform material plates 901 are arranged at equal intervals outside the feed port 902, and one side of the first connecting shaft 905 communicates with the output end of the driving motor 904. The model of the driving motor 904 is It can be ACM, and the driving motor 904 is fixedly connected to one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com