Automobile part machining device

A technology for auto parts and processing devices, which is applied in the direction of grinding drive devices, metal processing equipment, and parts of grinding machine tools, and can solve problems such as increasing work costs, increasing worker workload, and scrapping parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

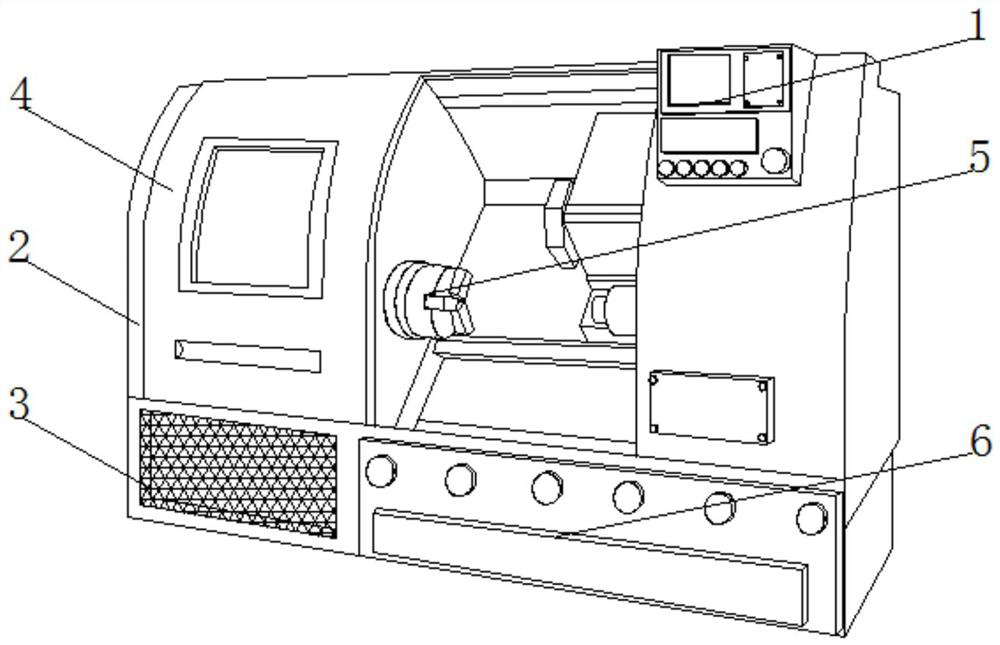

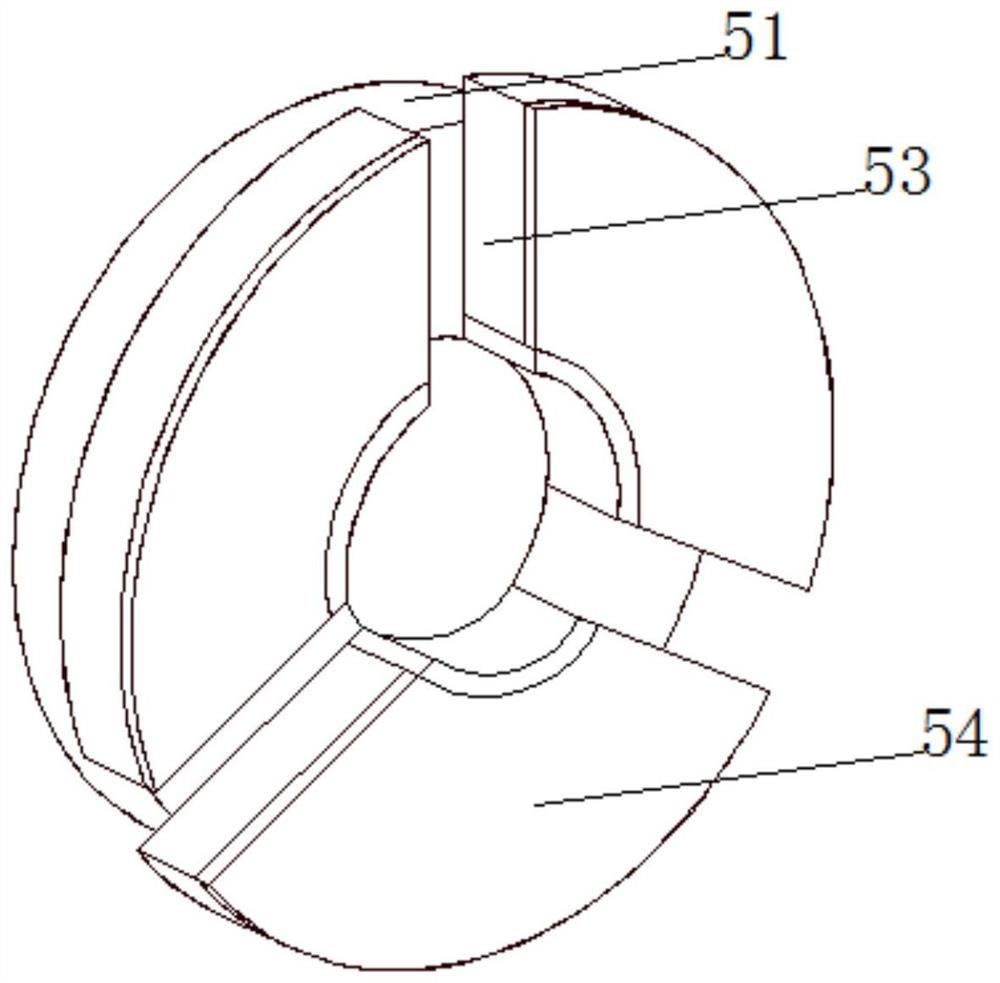

[0035] see Figure 1-3 , the present invention provides a technical solution: a processing device for auto parts, including a control panel 1, a body 2, a heat dissipation port 3, an opening and closing door 4, a spindle 5, a waste filter and discharge device 6, a control panel 1 and a body 2 The front end of the body is embedded and connected to the right, the heat dissipation port 3 and the body 2 are an integrated structure, the opening and closing door 4 is movably engaged with the body 2, the main shaft 5 is installed on the left side of the inner wall of the body 2, and the waste filter and discharge device 6 is connected to the body 2 connected, the main shaft 5 includes a chassis 51, a connecting block 52, a fixing seat 53, and a cover plate 54, the fixing seat 53 is threadedly connected with the connecting block 52 through a screw, the fixing seat 53 is slidingly connected with the chassis 51 through the connecting block 52, and the fixing seat 52 is away from One sid...

Embodiment 2

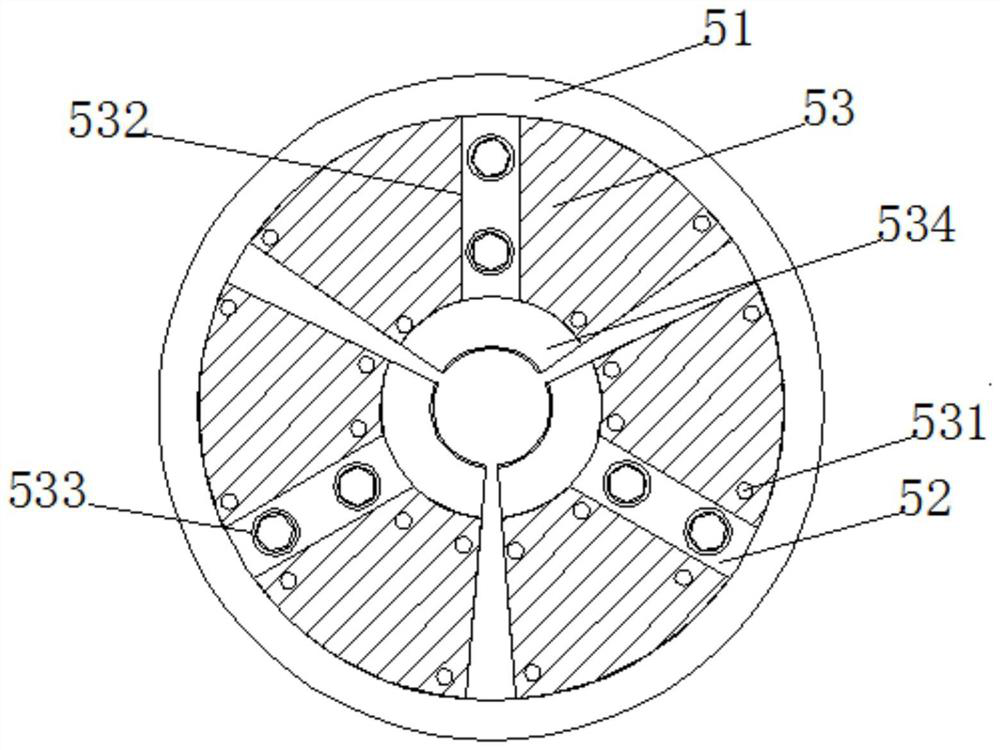

[0037] see Figure 3-4, on the basis of Embodiment 1, the present invention provides a technical solution: an auto parts processing device, the four corners of one side of the fixing seat 53 are provided with fixing slots 531, and the middle part of one side of the fixing seat 53 is provided with a rectangular slot 532, one side of the rectangular groove 532 is provided with a threaded hole 533, and the small diameter end of the fixed seat 53 is fixedly connected with a clamping mechanism 534, and the clamping mechanism 534 includes an arc-shaped connecting plate 341, a connecting air bag 342, an iron filings collection shell 343, a clip The holding device 344, the two ends of the arc-shaped connecting plate 341 are connected with the connecting air bag 342, and the side of the connecting air bag 342 away from the arc-shaped connecting plate 341 is fixedly connected with the iron filings collection shell 343, and the iron filings collecting shell 343 is far away from the side o...

Embodiment 3

[0039] see Figure 4-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a clamping device 344 of an auto parts processing device includes a connection intake housing 441, a connection reed 442, a moving column 443, an elastic ball 444, and a telescopic block 445, moving groove 446, the inner wall side connecting the air intake housing 441 is fixedly connected with the connecting reed 442, the connecting reed 442 is fixedly connected with the moving column 443 at the end far away from the connecting air intake housing 441, and the moving column 443 is away from the connecting reed One end of 442 penetrates through the intake housing 441 and is slidably connected with the moving groove 446, and the two sides connected to the intake housing 441 are fixedly connected with the telescopic block 445 through the elastic ball 444, and one side of the moving groove 446 is fixedly connected with a vulcanized rubber block. The moving column 443 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com