Corrugated paper cutting device

A cutting device and corrugated paper technology, applied in the field of corrugated paper, can solve problems such as unfavorable use of corrugated paper, loss of corrugated paper protection ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

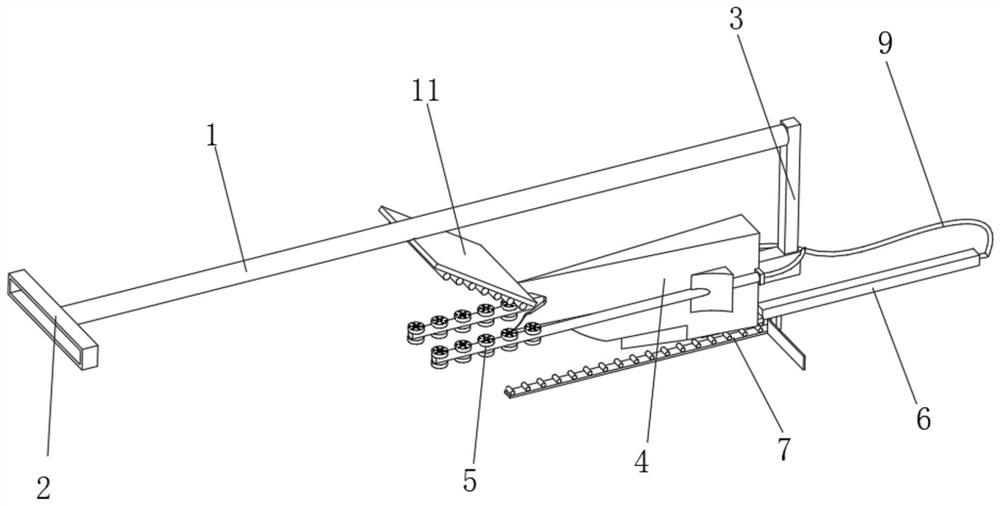

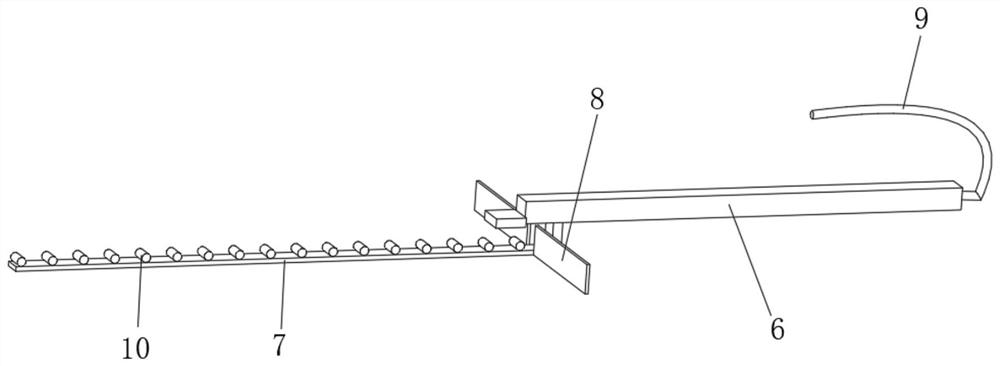

[0036] Such as Figure 1-2As shown, the present invention provides a technical solution: a corrugated paper cutting device, including a conductive link 1, the left side of the conductive link 1 is fixedly connected with a hand-held pull plate 2, and the end of the conductive link 1 away from the hand-held pull plate 2 is fixed An auxiliary baffle 3 is connected, one side of the bottom of the auxiliary baffle 3 is fixedly connected with a separation blade mechanism 4, and the front and rear ends of the separation blade mechanism 4 near the right side are fixedly connected with a stability limiting mechanism 5, and the back side of the separation blade mechanism 4 is close to The lower position is fixedly connected with an inflatable support mechanism 6, and the bottom of the inflatable support mechanism 6 is fixedly connected with a transmission base plate 7, and the front and rear ends of the connection between the inflatable support mechanism 6 and the transmission base plate ...

Embodiment 2

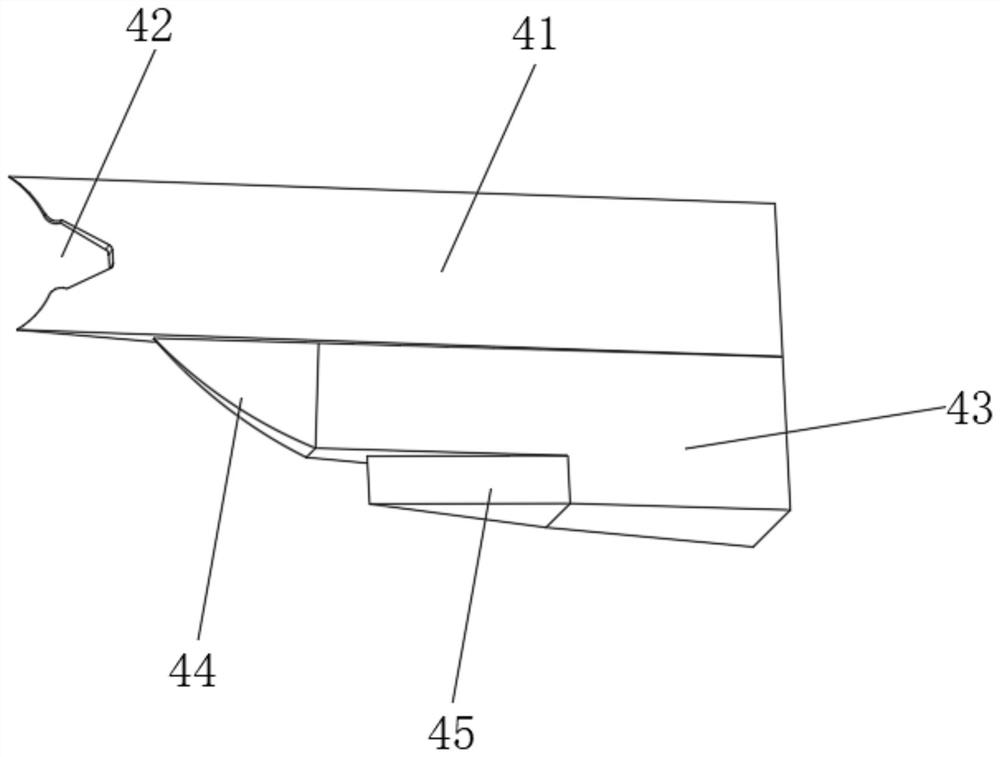

[0039] Such as image 3 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a corrugated cardboard cutting device, the separating blade mechanism 4 includes a cutting knife body 41, and the right side of the cutting knife body 41 is fixedly connected to the auxiliary baffle plate 3, The middle position on the left side of the cutting blade body 41 is fixedly connected with a top layer separation cut 42 .

[0040] The bottom of the cutter body 41 is fixedly connected with a cutter base 43, and the left side of the cutter base 43 is fixedly connected with a guide arc blade 44, and the guide arc blade 44 is arranged on the right side below the top layer separation otch 42. Finally, the upper, middle and lower parts of the corrugated paper are cut separately to avoid being squeezed and damaged when the corrugated paper corrugated core is cut, and to ensure the normal use of the corrugated paper after cutting.

[0041] The left side of the ...

Embodiment 3

[0043] Such as Figure 4 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a corrugated cardboard cutting device, the stability limiting mechanism 5 includes a corrugated hole rod 51, and an internal measurement and separation blade at one end of the corrugated hole rod 51 The right side surface of the mechanism 4 is fixedly connected, and the upper and lower ends of the corrugated hole bar 51 away from the side of the separating blade mechanism 4 are evenly and equidistantly connected with limiting guide wheels 52 for rotation. Now support the wavy core of corrugated paper to avoid deformation when the cutter contacts with corrugated paper.

[0044] The surface of the limiting guide wheel 52 away from the corrugated hole rod 51 is provided with punching nozzles 53 , the punching nozzles 53 communicate with the inside of the corrugated hole rod 51 , and the inside of the corrugated hole rod 51 communicates with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com