Automobile variable cross-section upper longitudinal beam with longitudinally segmented filling material, its use method and manufacturing method

A filling material and variable-section technology, which is applied in vehicle parts, superstructure, transportation and packaging, etc., can solve the problems of easy bending, can not ensure the safety of passengers in the car, and can not get crushed, wrinkled and deformed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

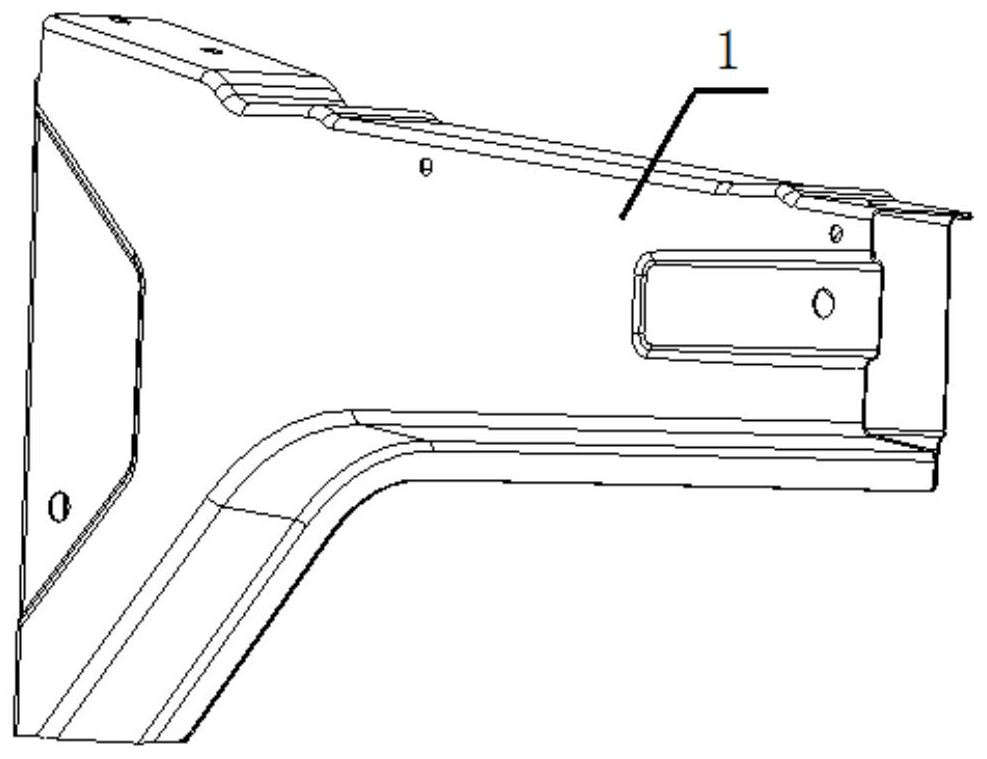

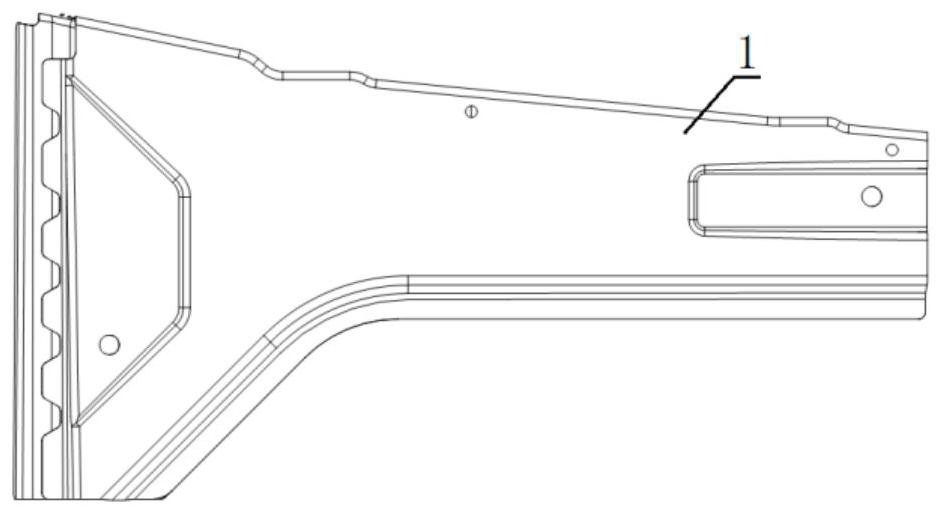

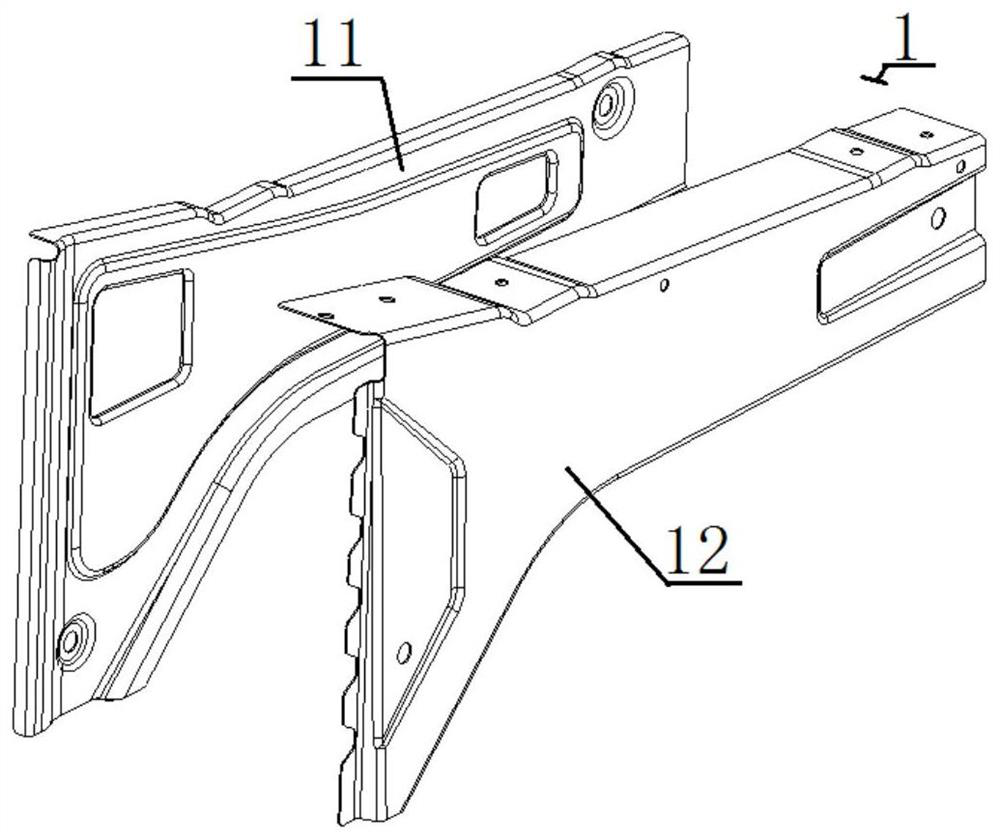

[0043] Figure 1-5 Shown is an automotive variable-section upper side rail with longitudinally segmented filling material, which includes an upper side beam shell 1; a multi-section filling material inside the upper side beam shell 1; and the structural glue 2 between adjacent sections of filling material. The filling material is composed of multi-section energy-absorbing materials 3 and rigid structural materials 4. The energy-absorbing materials 3 are arranged at the front end that is impacted, and the rigid structural materials 4 are arranged at the rear end that needs to be loaded. The continuous segment of energy-absorbing material 3 between the rear ends is adjacent to the rigid structural material 4, and the energy-absorbing material 3 of a single segment between the front end and the rear end is also adjacent to the rigid structural material 4.

[0044] Since the energy-absorbing material 3 is provided at the front end of the upper longitudinal beam shell 1, it can abs...

Embodiment 2

[0054] The present invention also relates to a method for using longitudinally sectioned longitudinal beams with variable cross-section filling materials. When encountering a frontal collision, the energy-absorbing material 3 filled at the front end of the impacted upper longitudinal beam shell 1 fully absorbs the impact Energy, then the rigid structural material 4 of the middle section adjacent to the front end energy-absorbing material 3 maintains the structural strength or rigidity of the upper longitudinal beam, and then the middle section energy-absorbing material 3 of the rigid structural material 4 adjacent to the middle section continues Absorb the remaining collision energy, and finally the rigid structural material 4 at the rear end blocks the remaining collision force.

[0055] Since the frontal collision will lead to crushing, wrinkling and deformation of the upper longitudinal beam, an energy-absorbing material 3 is arranged at the front end of the upper longitudin...

Embodiment 3

[0059] The present invention relates to a method for manufacturing an automobile variable-section upper longitudinal beam of the above-mentioned longitudinal section filling material, which specifically includes the following steps:

[0060] S1: Manufacture upper stringer shell 1;

[0061] S2: Coating structural glue 2 on the inner surface of the upper longitudinal beam shell 1;

[0062] S3: Fill energy-absorbing material 3 and rigid structural material 4 in the upper stringer shell 1, keep the front end of the upper stringer shell 1 filled with energy-absorbing material 3, and fill the rear end of the upper stringer shell 1 with a rigid structure Material 4, the energy-absorbing material 3 of the continuous section between the front end and the rear end needs to be adjacent to the rigid structural material 4 when filling, and the energy-absorbing material 3 of a single segment between the front end and the rear end must also be adjacent to the rigid structural material 4 when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com