Method for preparing nickel-cobalt-manganese ternary precursor with narrow particle size distribution

A narrow particle size distribution, nickel-cobalt-manganese technology, applied in the direction of chemical instruments and methods, electrical components, nickel compounds, etc., can solve the problems of wide particle size distribution of large particle products, failure to meet customer needs, low pH and low speed, etc., to achieve consistency Good performance, simple operation, and the effect of reducing the width of particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

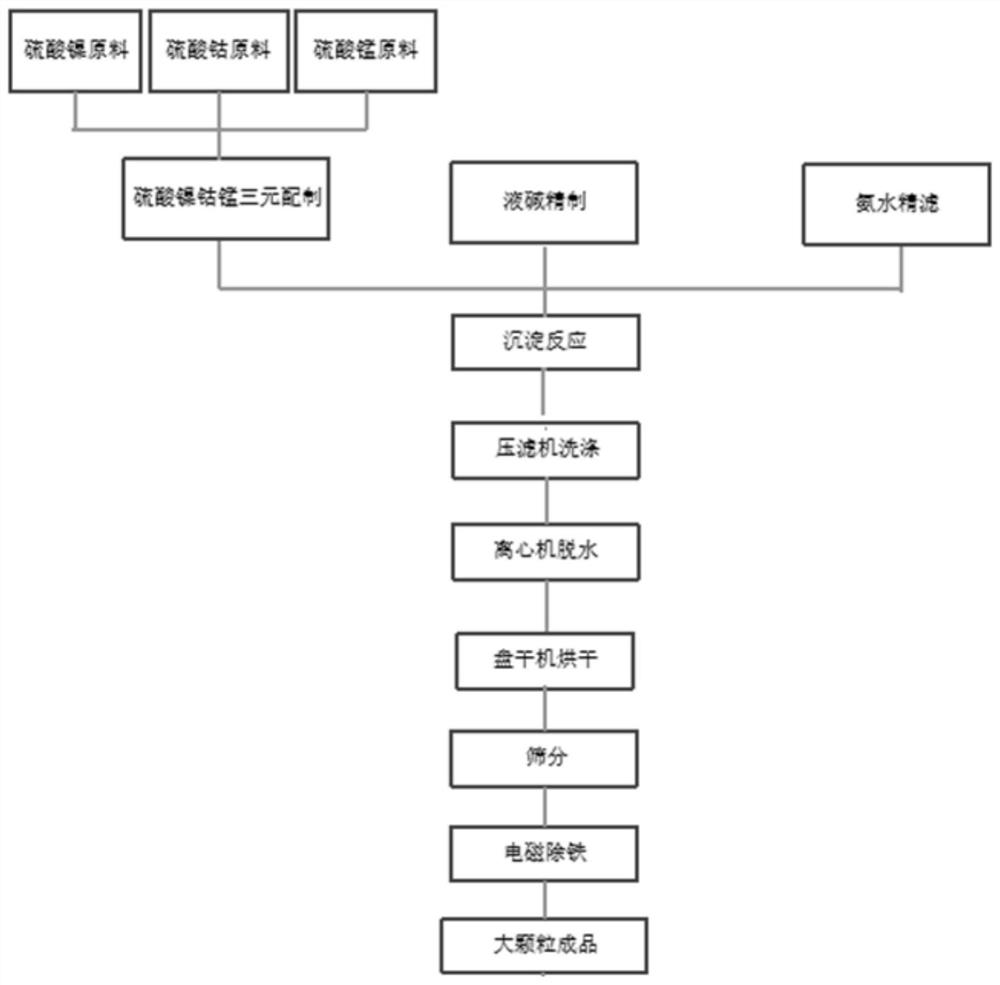

Image

Examples

Embodiment 1

[0017] will Ni 2+ 、Co 2+ , Mn 2+ Prepare a nickel-cobalt-manganese sulfate solution with a total metal concentration of 120g / L at a molar ratio of 34.8:34.0:34.2; 3 Prepare pH = 12, ammonia concentration = 9.5g / L, temperature is 65°C, and volume is 7.5m 3 The bottom liquid of the reaction kettle is fed with a nitrogen flow rate of 0.5m 3 / h, under the conditions of reaction temperature 65°C and reaction kettle stirring speed 350r / min, the above-mentioned salt solution, 20% ammonia solution and 35% liquid caustic soda are simultaneously added into the kettle through the corresponding liquid inlet pipe for reaction synthesis , in the first 8 hours of the reaction, while the dosage of nickel-cobalt-manganese sulfate solution was fixed at 200L / h, the dosage of liquid caustic soda and ammonia water was adjusted to lower and stabilize the pH at 10.5, and maintain the ammonia concentration at 9.0g / L. During the period from 8 hours to the end of the reaction, while fixing the dosa...

Embodiment 2

[0019] will Ni 2+ 、Co 2+ , Mn 2+ Prepare a nickel-cobalt-manganese sulfate solution with a total metal concentration of 100g / L at a molar ratio of 32.8:32.0:32.2; 3 Prepare pH = 11, ammonia concentration = 10.9g / L, temperature 55°C, volume 7.0m 3 The bottom liquid of the reaction kettle is fed with a nitrogen flow rate of 3m 3 / h, under the conditions of a reaction temperature of 55°C and a stirring speed of the reactor of 250r / min, the above-mentioned nickel-cobalt-manganese sulfate solution, 10% ammonia solution and 25% liquid caustic soda are simultaneously added to the kettle through the corresponding liquid inlet pipe Carry out reaction synthesis, within 8 hours in the early stage of the reaction, while fixing the dosage of nickel-cobalt-manganese sulfate solution at 250L / h, adjust the amount of liquid caustic soda and ammonia water so that the pH drops and stabilizes at 10.8, and the ammonia concentration maintains 10.5g / L. 8h to the end of the reaction, while fixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com