A method for producing fish collagen peptides from tilapia scale raw materials

A technology for fish collagen peptide and fish scale collagen, which is applied in the field of fish collagen peptide preparation, can solve the problems of complex extraction product components, troublesome purification and poor uniformity, etc., and achieves the improvement of resource utilization, yield, and molecular weight concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

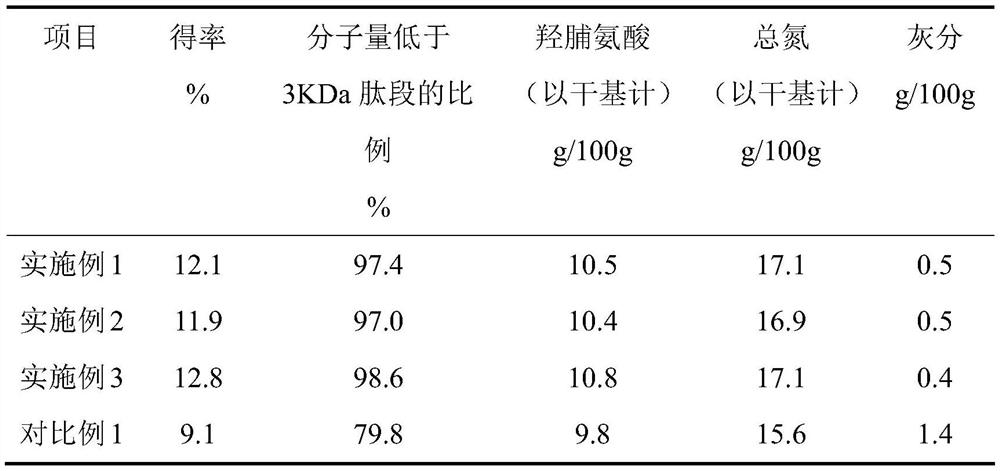

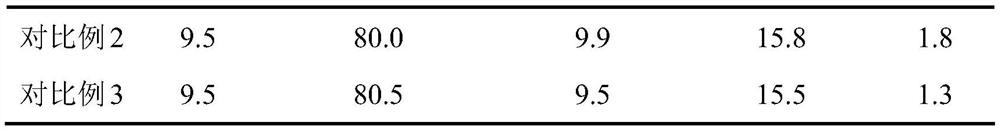

Embodiment 1

[0030] A method for producing fish collagen peptides from tilapia scale raw materials is prepared by the following steps:

[0031] 1) Pretreatment: add the cleaned tilapia scales to 0.05mol / L NaOH solution, stir for 8-10 hours, and control the water; then soak in 0.04mol / L HCl solution for 2 hours, and control the water; Finally, add it to the compound solution and soak for 50 minutes, wash with water until neutral, and obtain pretreated fish scales;

[0032] 2) Activation treatment: add the pretreated fish scales to the activation solution, soak at 35°C for 4 hours, raise the temperature to 90°C, keep for 5 minutes, naturally cool to room temperature, wash with water, control the moisture, dry, crush and pass through an 80-mesh sieve , to obtain activated fish scale powder;

[0033] 3) Extraction of collagen: mix activated fish scale powder, acid protease and deionized water, extract at 45±2°C and pH=6 for 3 hours, centrifuge, collect supernatant, and obtain primary collagen...

Embodiment 2

[0043] A method for producing fish collagen peptides from tilapia scale raw materials is prepared by the following steps:

[0044] 1) Pretreatment: add the cleaned tilapia scales to 0.05mol / L NaOH solution, stir for 8-10 hours, and control the water; then soak in 0.04mol / L HCl solution for 2 hours, and control the water; Finally, add it to the compound solution and soak for 30 minutes, wash with water until neutral, and obtain pretreated fish scales;

[0045] 2) Activation treatment: add the pretreated fish scales to the activation solution, soak at 45°C for 2 hours, raise the temperature to 95°C, keep for 3 minutes, naturally cool to room temperature, wash with water, control the moisture, dry, crush and pass through a 100-mesh sieve , to obtain activated fish scale powder;

[0046] 3) Extraction of collagen: mix activated fish scale powder, acid protease and deionized water, extract at 45±2°C, pH=6 for 1 hour, centrifuge, collect supernatant, and obtain primary collagen liq...

Embodiment 3

[0056] A method for producing fish collagen peptides from tilapia scale raw materials is prepared by the following steps:

[0057] 1) Pretreatment: add the cleaned tilapia scales to 0.05mol / L NaOH solution, stir for 8-10 hours, and control the water; then soak in 0.04mol / L HCl solution for 2 hours, and control the water; Finally, add it to the compound solution and soak for 40 minutes, wash with water until neutral, and obtain pretreated fish scales;

[0058] 2) Activation treatment: Add the pretreated fish scales to the activation solution, soak at 40°C for 3 hours, raise the temperature to 92°C, keep for 4 minutes, naturally cool to room temperature, wash with water, control the moisture, dry, crush and pass through a 90-mesh sieve , to obtain activated fish scale powder;

[0059] 3) Extraction of collagen: mix activated fish scale powder, acid protease and deionized water, extract at 45±2°C, pH=6 for 2 hours, centrifuge, collect supernatant, and obtain primary collagen liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com