A kind of rh pre-evacuation device and method

A pre-evacuation and vacuum chamber technology, applied in the field of RH pre-evacuation devices, can solve the problems of inability to have a vacuum degree and difficulty in opening the main valve, and achieve the effect of improving the RH efficiency and reducing the difficulty of opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

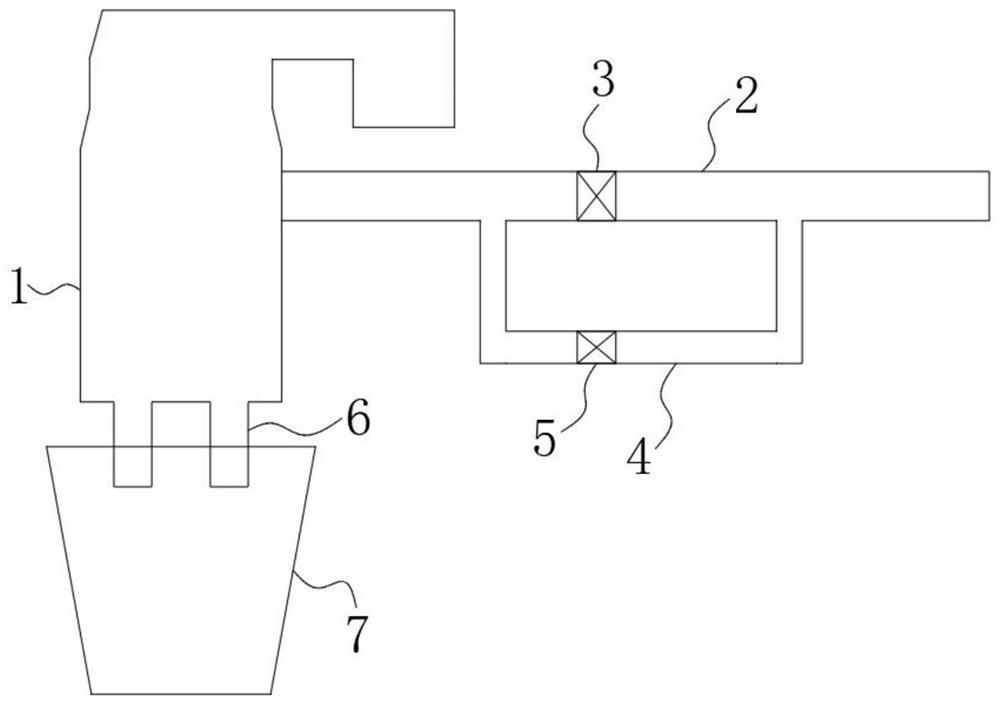

[0038] In the prior art, before RH, the main valve is closed first, and the air extraction pipeline is pre-evacuated by a vacuum system, so that the air extraction pipeline has a certain degree of vacuum. During the RH process, the main valve is opened, the vacuum chamber gradually forms a vacuum degree through the pumping pipeline, and then RH is performed on the molten steel. Since the main valve is in a low vacuum degree on one side of the vacuum system and is in a normal pressure state on the side of the vacuum chamber, it is difficult to open the main valve. And in the whole vacuum process, the vacuumization speed of the vacuum chamber 1 is slow.

[0039] Among them, the RH mentioned in the present invention refers to the molten steel vacuum circulation refining method. The RH front mentioned in the present invention refers to the time when the vacuum chamber is not in contact with the molten steel, and at this time, the vacuum system is used to pre-evacuate the pumping ...

Embodiment 2

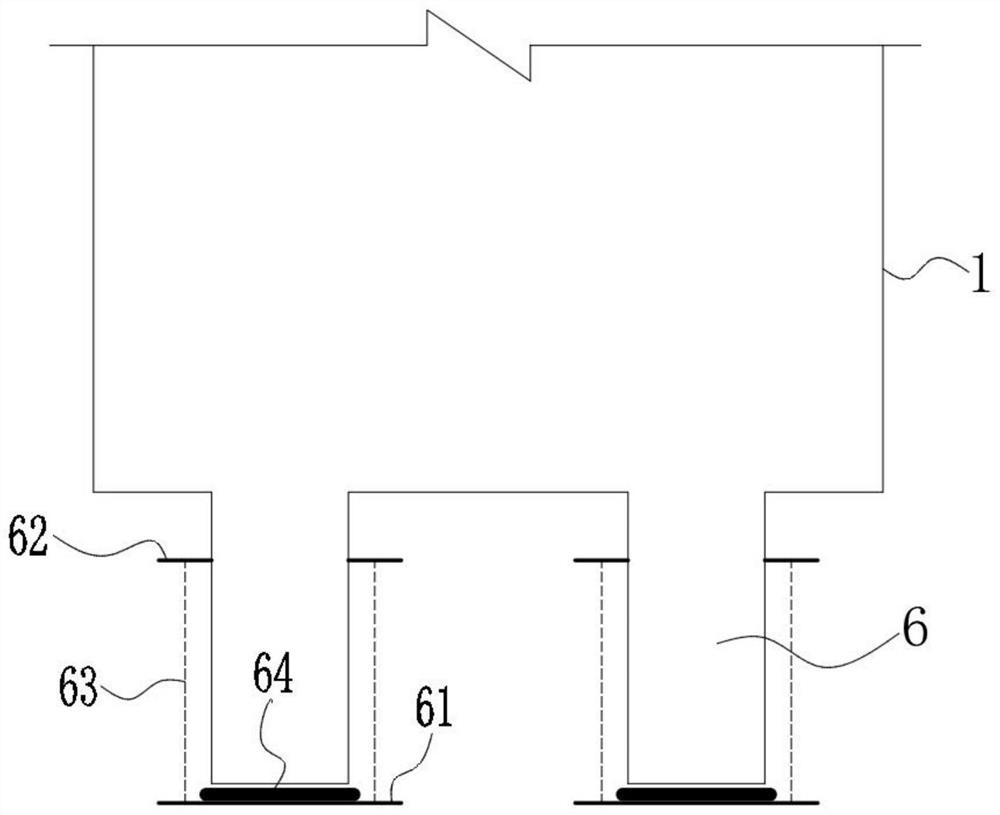

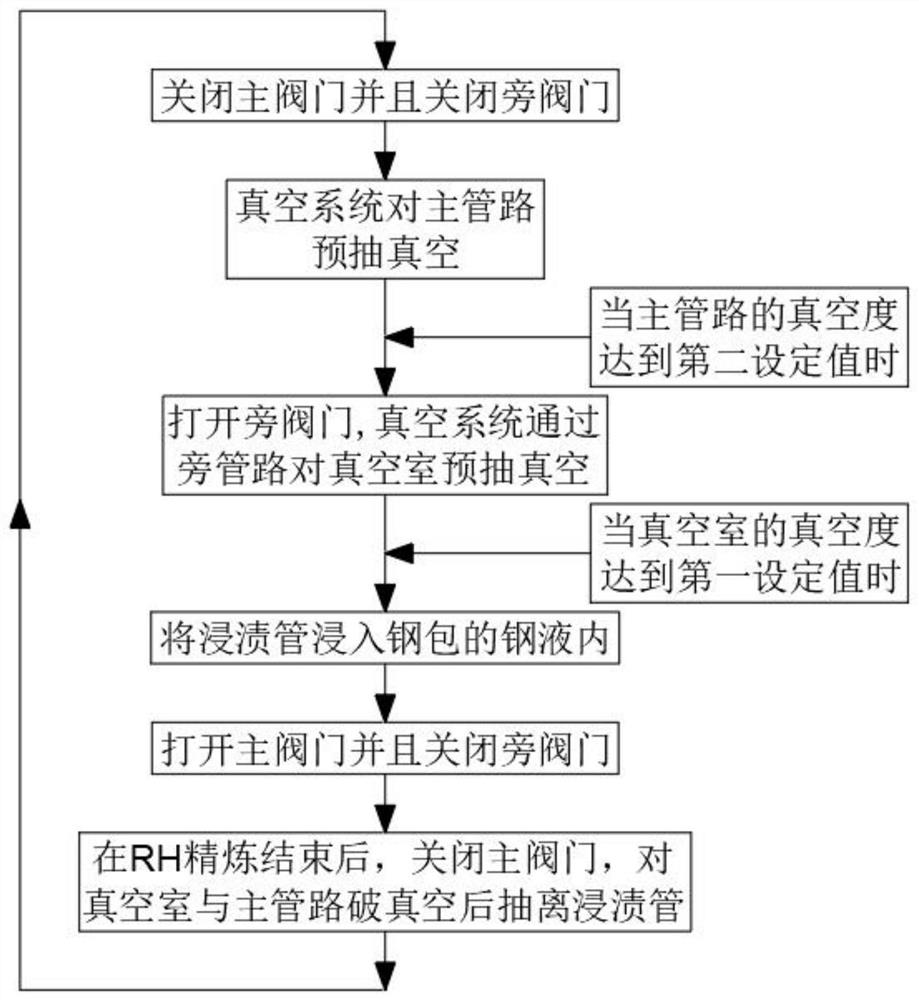

[0046] In the second aspect, the present invention also provides a RH pre-evacuation method, such as image 3As shown, close the main valve 3 and open the side valve 5 before RH to start the vacuum system. Since the dip tube 6 has been blocked by the blocking device, the vacuum system pre-evacuates the vacuum chamber 1 through the bypass line 4 . When the vacuum degree of the vacuum chamber 1 reaches the first set value, wait for the molten steel to be processed. Then the ladle 7 is lifted to the position of the dip tube 6, the dip tube 6 is immersed in the molten steel of the ladle 7, the main valve 3 is opened and the side valve 5 is closed. The blocking plate 61 and the sealing member 64 dissolve into the molten steel, and the molten steel enters the vacuum chamber 1 through the dip tube 6 under the action of atmospheric pressure for RH. After the RH is over, close the main valve 3, and perform vacuum breaking treatment on the vacuum chamber 1 on one side of the main valv...

Embodiment 3

[0051] A 210t RH vacuum chamber 1 is selected, the diameter of the main pipeline 2 is set to 1500mm, and the diameter of the bypass pipeline 4 is set to 250mm. When the vacuum degree of the main line 2 reaches 0.02MPa, the side valve 5 is opened. Continue to pre-evacuate the vacuum chamber 1 through the bypass pipeline 4. When the vacuum degree of the vacuum chamber 1 reaches 0.05MPa, close the side valve 5 and prepare to vacuum the molten steel in the ladle 7. In the whole pre-evacuation process, it is measured that the time for the existing RH vacuum chamber 1 to reach a deep vacuum is 5 minutes, and the time for the RH vacuum chamber 1 of the present invention to reach a deep vacuum is 3.5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com