Automatic fixing piling device

A technology of piling device and fixing device, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., and can solve problems such as single function and inability to fix wooden piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

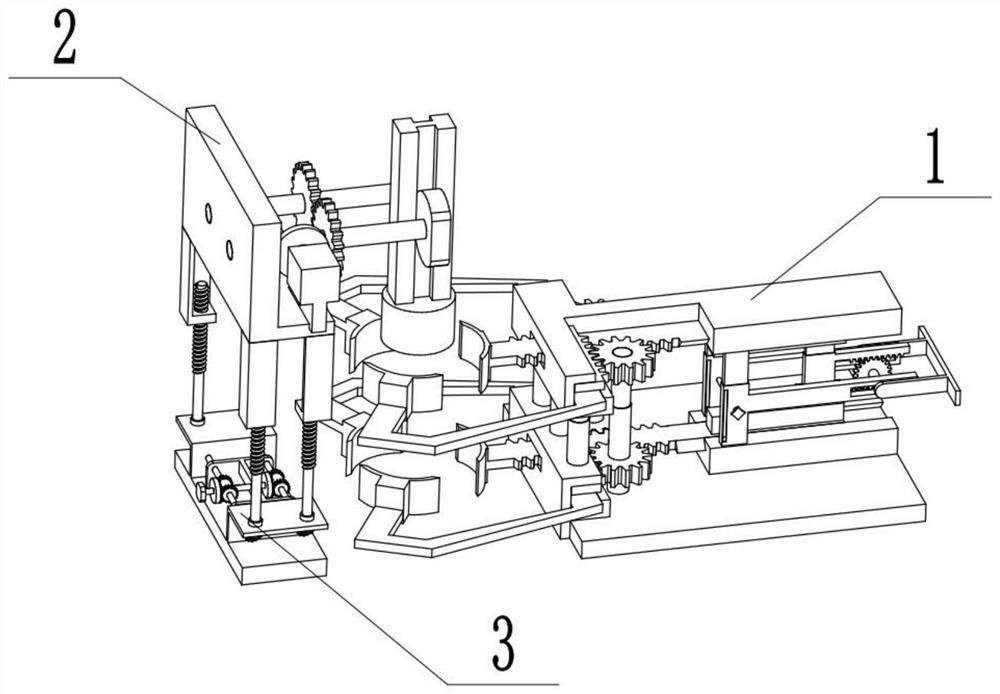

[0028] Combine below Figure 1-12 Describe this embodiment, an automatic fixed piling device, including a fixing device 1; a piling device 2;

specific Embodiment approach 2

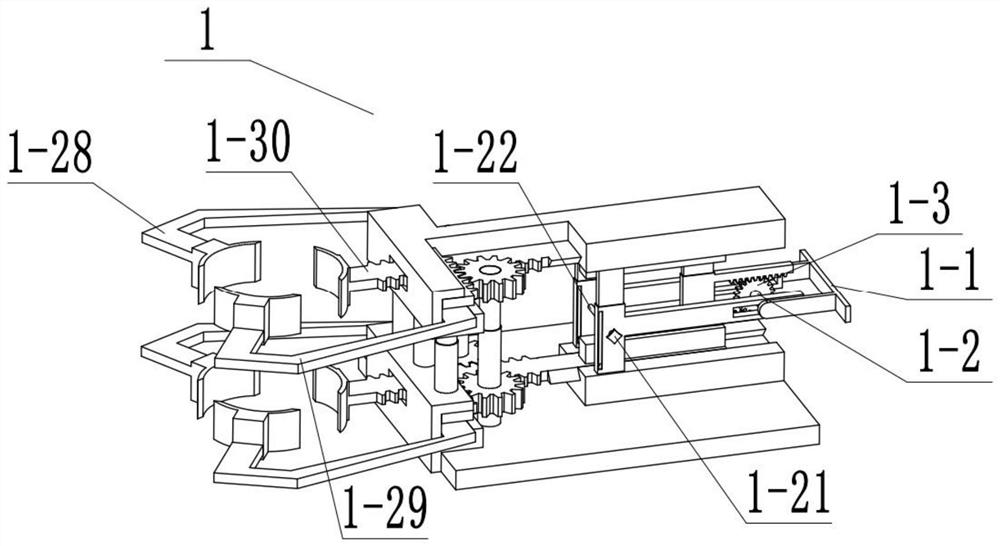

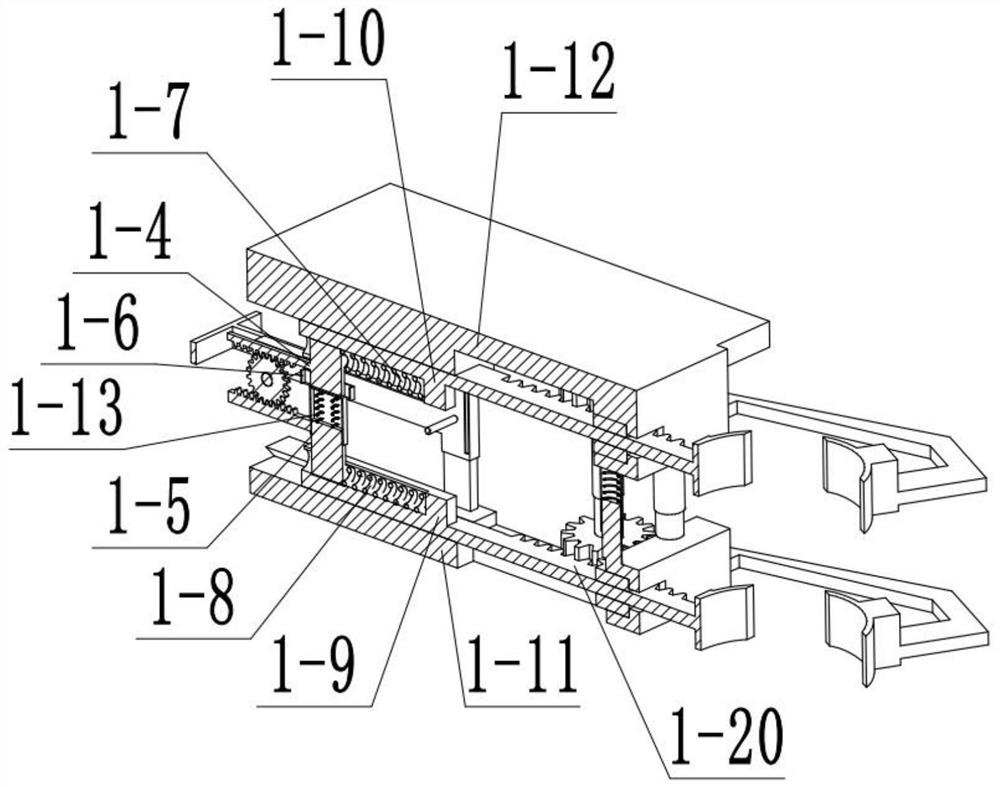

[0030] Combine below Figure 1-12Describe this embodiment, this embodiment will further explain Embodiment 1, the described fixing device 1 includes a push rod 1-1; a rotating shaft 1-2; a gear 1-3; an upper slider 1-4; a lower slider 1-5; notch slider 1-6; upper spring 1-7; lower spring 1-8; lower rod 1-9; upper slider 1-10; lower base 1-11; upper base 1-12; tension Spring one 1-13; Gear two 1-14; Small cylinder one 1-15; Gear three 1-16; Small cylinder two 1-17; Lower power arm one 1-18; Lower power arm two 1-19; Lower power Arm three 1-20; Turn button 1-21; Rotating shaft two 1-22; Pinion 1-23; Vertical tooth 1-24; Tension spring two 1-25; Vertical pipe 1-26; Small cylinder three 1-27; Upper power arm one 1-28; upper power arm two 1-29; upper power arm three 1-30, both ends of the rotating shaft one 1-2 are fixedly connected with the push rod 1-1, and the rotating shaft one 1-2 is connected with the gear one 1 -3 rotating connection, gear one 1-3 is connected with upper s...

specific Embodiment approach 3

[0033] Combine below Figure 1-12 Illustrate this embodiment, this embodiment will further explain Embodiment 1, described piling device 2 comprises fixed boss 2-1; Motor 2-2; Runner 2-3; Gear four 2-4; Motor slider 2 -5; cylinder three 2-6; heterosexual wheel 2-7; vertical bar 2-8; left groove 2-9; round wheel 2-10; gear five 2-11; Gravity column 2-14; Motor notch 2-15, motor 2-2 is fixedly connected with runner 2-3, runner 2-3 is connected with gear four 2-4, motor 2-2 is connected with motor slide block 2 -5 is fixedly connected, gear four 2-4 is fixedly connected with cylinder three 2-6, fixed boss 2-1 is rotationally connected with cylinder three 2-6, cylinder three 2-6 is fixedly connected with opposite sex wheel 2-7, left groove 2-9 is arranged on the vertical rod 2-8, the opposite sex wheel 2-7 is connected with the left groove 2-9, the right groove 2-13 is arranged on the vertical rod 2-8, and the round wheel 2-10 is connected with the right groove 2-9. 13 is mating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com