Waterproof construction method for convex skylight of steel structure roof

A steel structure and skylight technology, applied in the direction of skylight/dome, can solve the problems of rising construction and maintenance costs, affecting the appearance of the building exterior, and poor waterproof quality of skylights, achieving low maintenance costs in the later stage, good promotion and application prospects and value, Good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

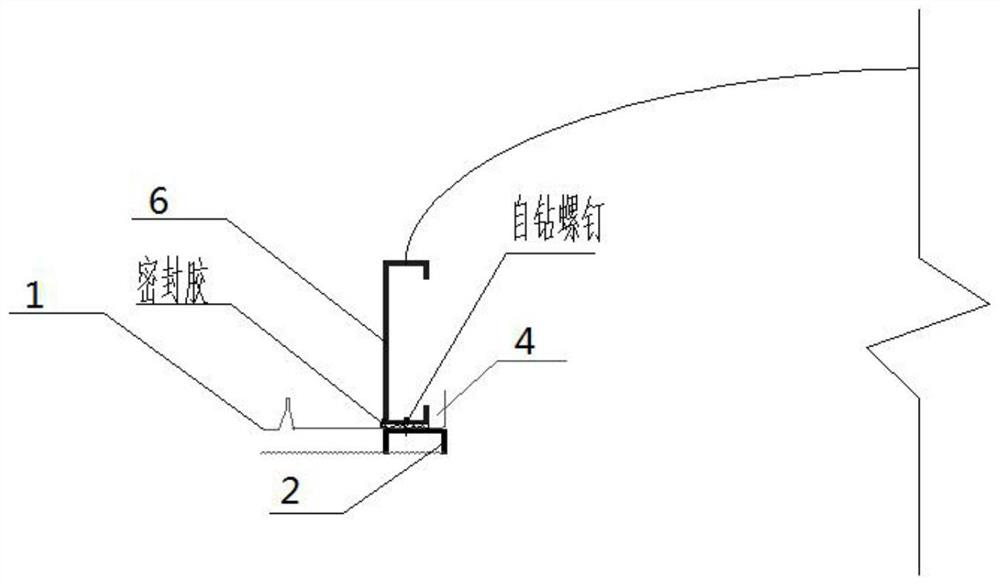

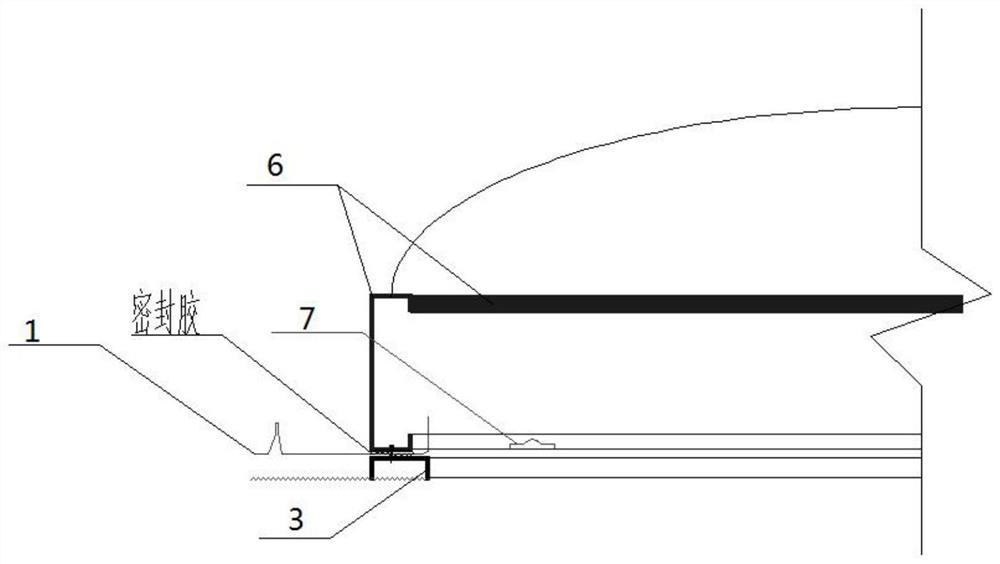

[0031] The steel structure roof raised skylight waterproof construction method of the present invention comprises the following steps:

[0032] S1. Construction preparation: drawing construction drawings and purchasing materials;

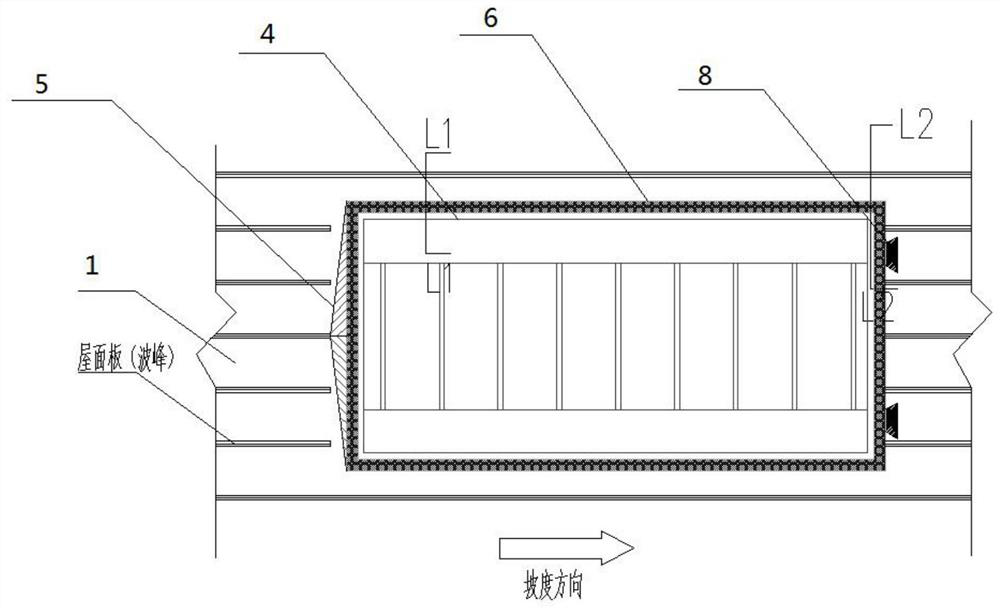

[0033] S2. Construction positioning: Determine the position of the skylight opening on the roof panel according to the drawings and perform positioning by marking, and reduce the size of each side of the opening by 50mm for later production of the internal diversion groove, and lay pedestrian passages around the opening of the skylight to prevent falling from high altitude;

[0034] S3. Opening cutting: Drill four holes with a diameter of 12mm at the four corners of the defined skylight opening, and use a reciprocating saw blade to cut off all the peaks at the roof where the skylight is installed, and then use a hand-held shears to cut the roof In the flat area, avoid the insulation cotton, fold up the cut roof panel and remove it, and clean the roo...

Embodiment 2

[0045] Dingyu logistics warehousing project 2# logistics warehouse project: the structure type is steel structure, the ground floor is partly two floors, the construction area is 3052㎡, the start date is October 8, 2018, the construction method is the same as the embodiment, and the completion date is 2019 On October 8, after the installation was completed, a single-stage water spray test was carried out, and there was no water seepage or wet stains, and it has been used so far without damage.

Embodiment 3

[0047]Construction of Beijing Jiaotong University Seaside Rail Transit Comprehensive R&D Experimental Base (Tender 1)-B7# project: the structure is a portal steel frame light steel structure, the ground floor is partly two floors, the construction area is 4520.97㎡, and the start date is April 2018 On the 5th, the construction method was the same as that of the embodiment, and the completion date was May 31, 2019. After the installation was completed, a single-stage water spray test was carried out, and there was no water seepage or wet stains, and it has been used so far without damage.

[0048] The steel structure roof raised skylight waterproof construction technology used in Examples 1-3 uses the double waterproof construction method of outer deflector + inner diversion groove, which can not only ensure the waterproof purpose of installing raised components on the steel structure roof, but also achieve economical efficiency. Aesthetic effect. The construction components are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com