Damping and leveling assembly structure and mounting method thereof

A component structure and leveling technology, applied in building structure, floor, covering/lining, etc., can solve the problems of easily damaged component structure, reduce component service life, inconvenient operation, etc., to increase its own strength and avoid shrinkage deformation. , The effect of obvious foolproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to more clearly illustrate the embodiments of the present invention and the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations. In addition, the belonging of the design orientation only indicates the relative positional relationship between the components, not the absolute positional relationship.

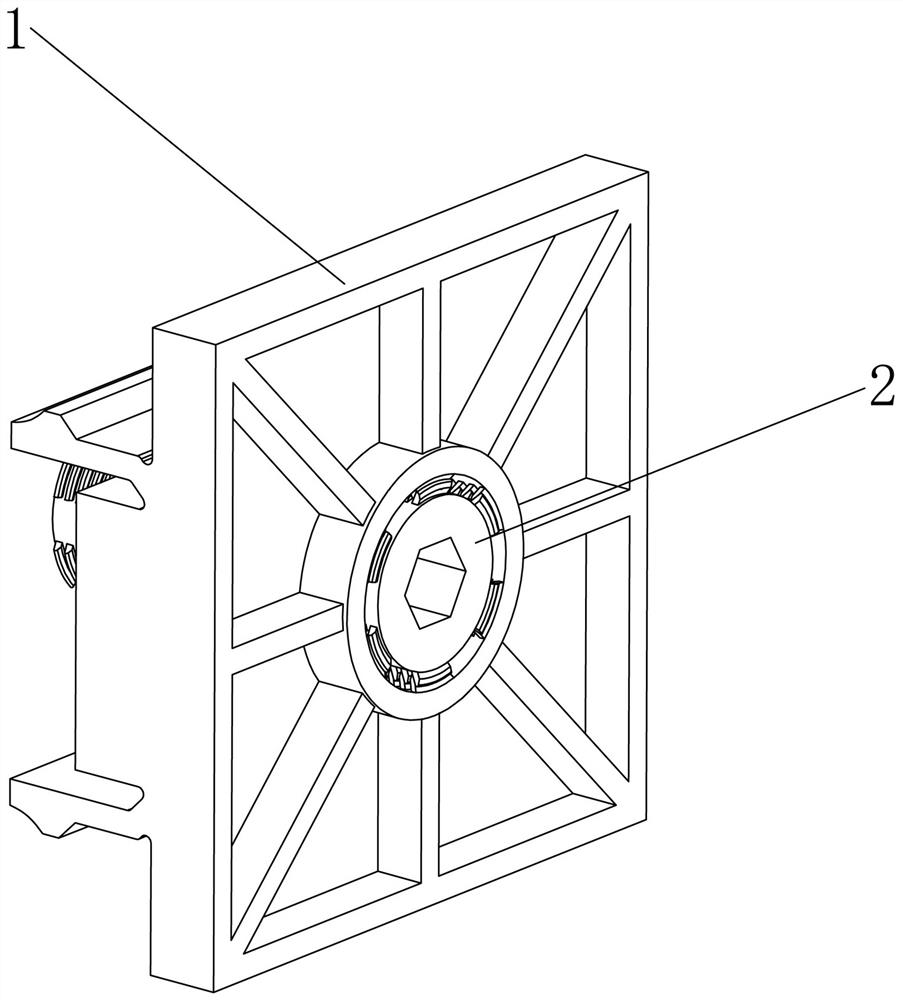

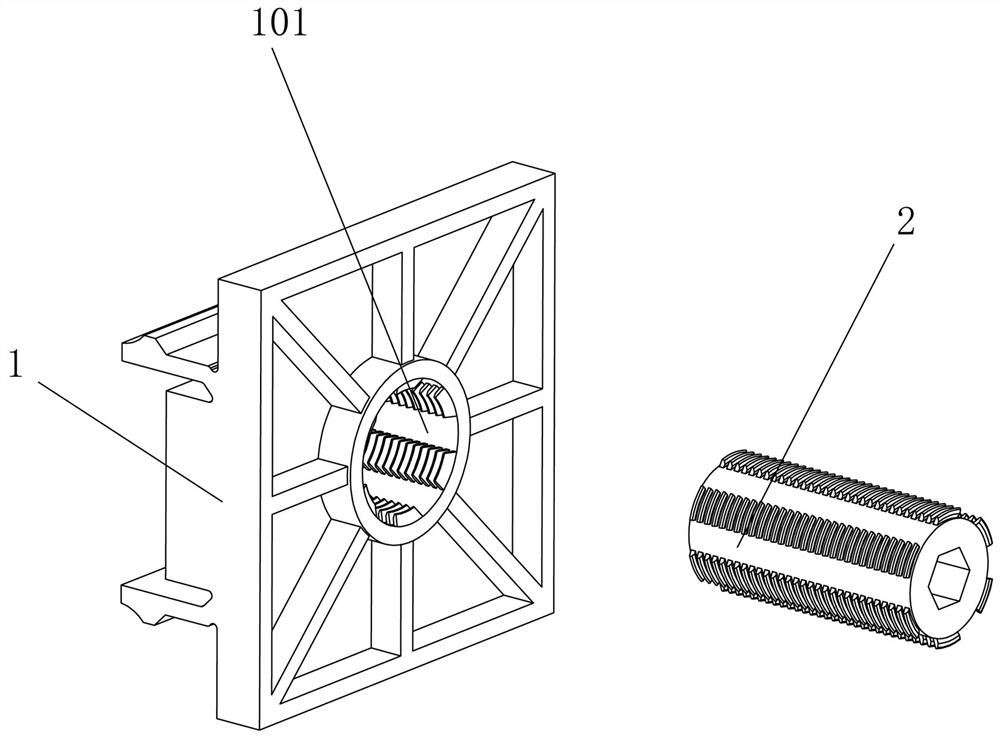

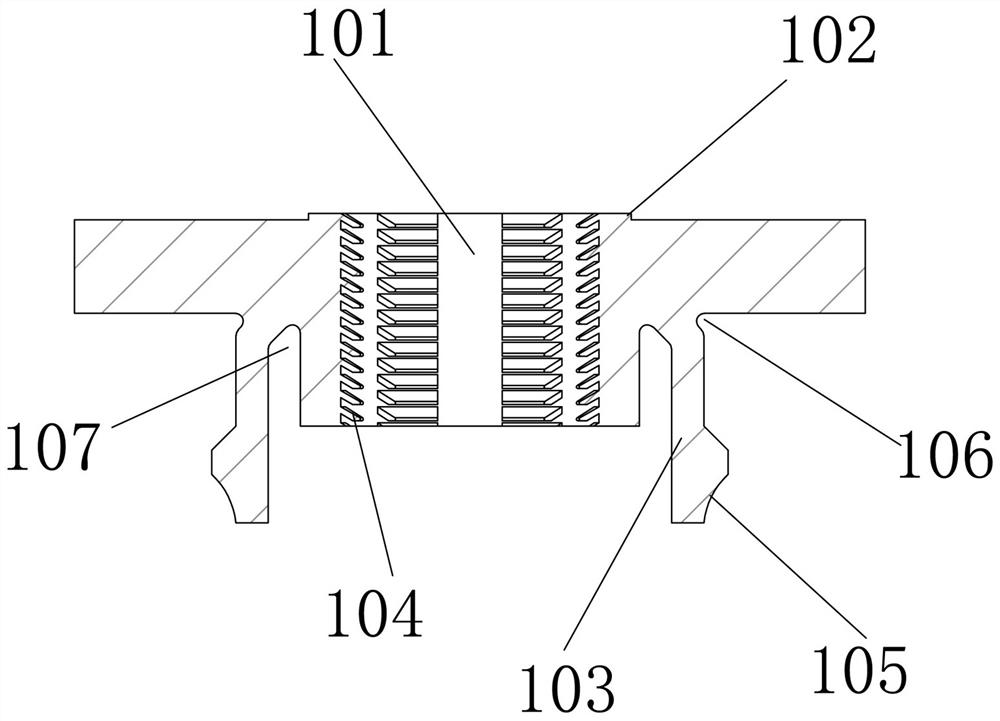

[0037] In order to realize the efficient production, processing and installation of assembled interior leveling products, in the embodiment of the present invention, the vibration-absorbing leveling component structure is composed of a support base and leveling studs, all of which are manufactured by injection mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com