Installation anchoring device of composite heat preservation formwork and using method of installation anchoring device

A technology of composite thermal insulation and anchoring device, which is applied in the direction of thermal insulation, formwork/formwork/work frame connectors, formwork/formwork/work frame, etc., which can solve the problem of lack of uniformity in the installation of composite thermal insulation formwork, easy damage to the insulation layer, and lower Heat insulation effect and other issues, to improve the quality of installation and anchoring, to facilitate plugging, and to ensure the effect of anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

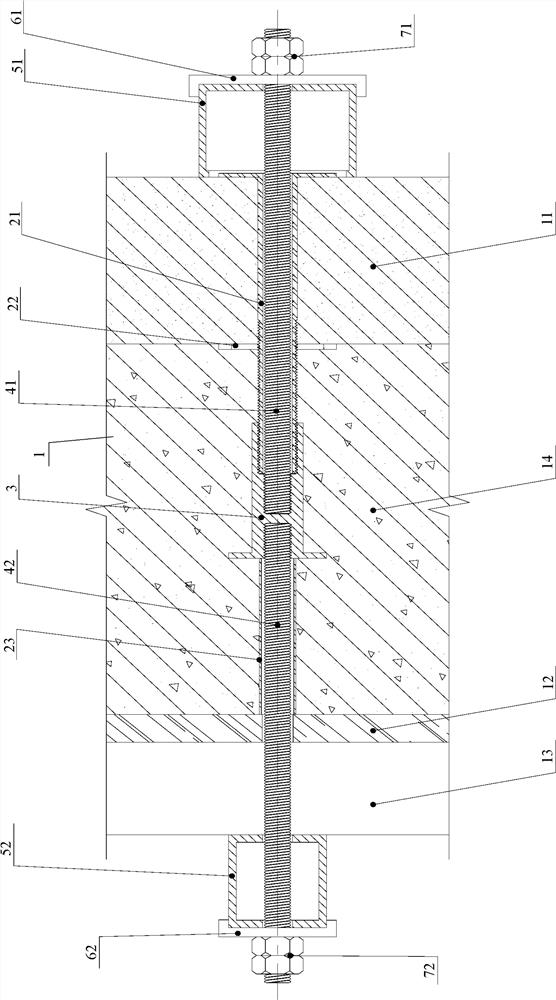

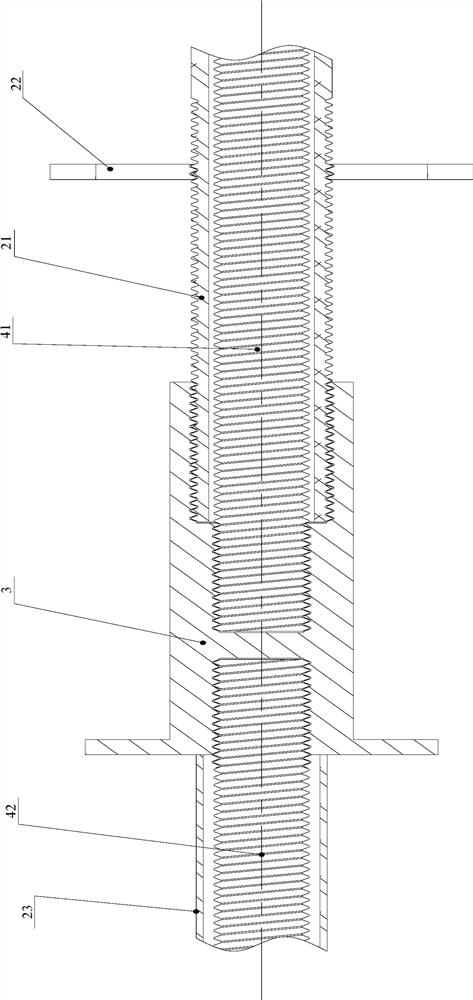

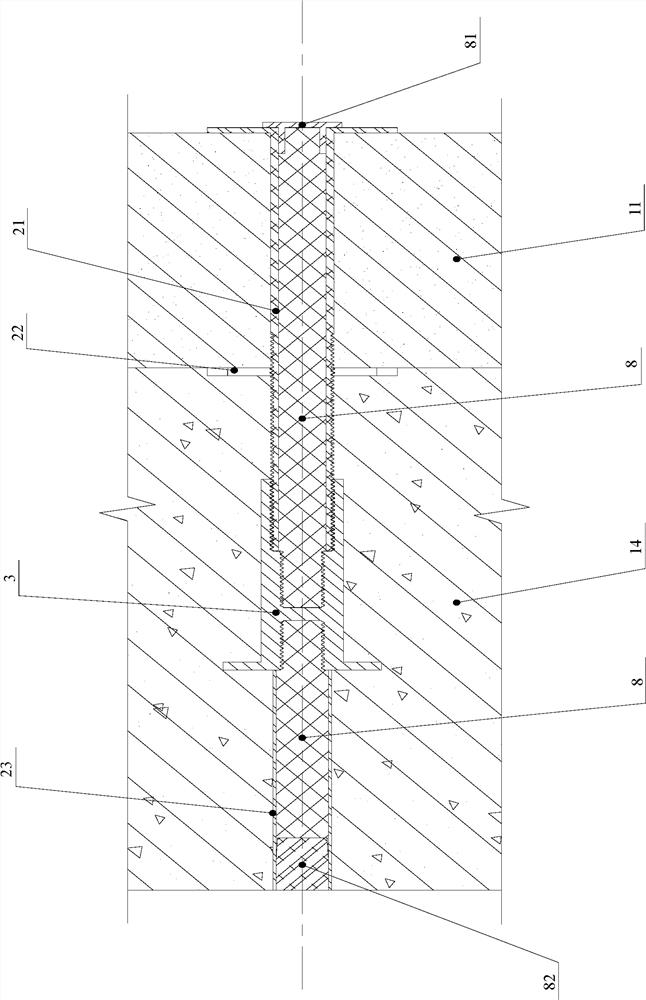

[0039] An installation and anchoring device for a composite thermal insulation formwork, comprising a composite thermal insulation formwork 11, an inner template 12, a keel 13, an outer sleeve 21, a gland 22, an inner sleeve 23, an anchor connector 3 for tension, an outer pull screw 41, an inner pull Screw rod 42, outer square pipe 51, inner square pipe 52, outer pressing plate 61, inner pressing plate 62, outer nut 71 and inner nut 72, as figure 1 and figure 2 As shown, the specific structure is:

[0040] Both the composite thermal insulation formwork 11 and the inner formwork 12 are vertical and are arranged facing each other through their respective inner surfaces. The area between the inner formwork 11 and the outer wall composite formwork 12 forms a pouring area 1, and pouring in the pouring area 1 Concrete 14, the inner surface of the keel 13 is attached to the outer surface of the inner formwork 12;

[0041]The outer surface of the outer sleeve 21 is provided with ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com