anti-corrosion oil pipeline

A technology for oil pipelines and oil pipes, which is applied in pipeline anticorrosion/rust protection, damage protection, and pipeline protection. Guaranteed sealing performance and improved anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

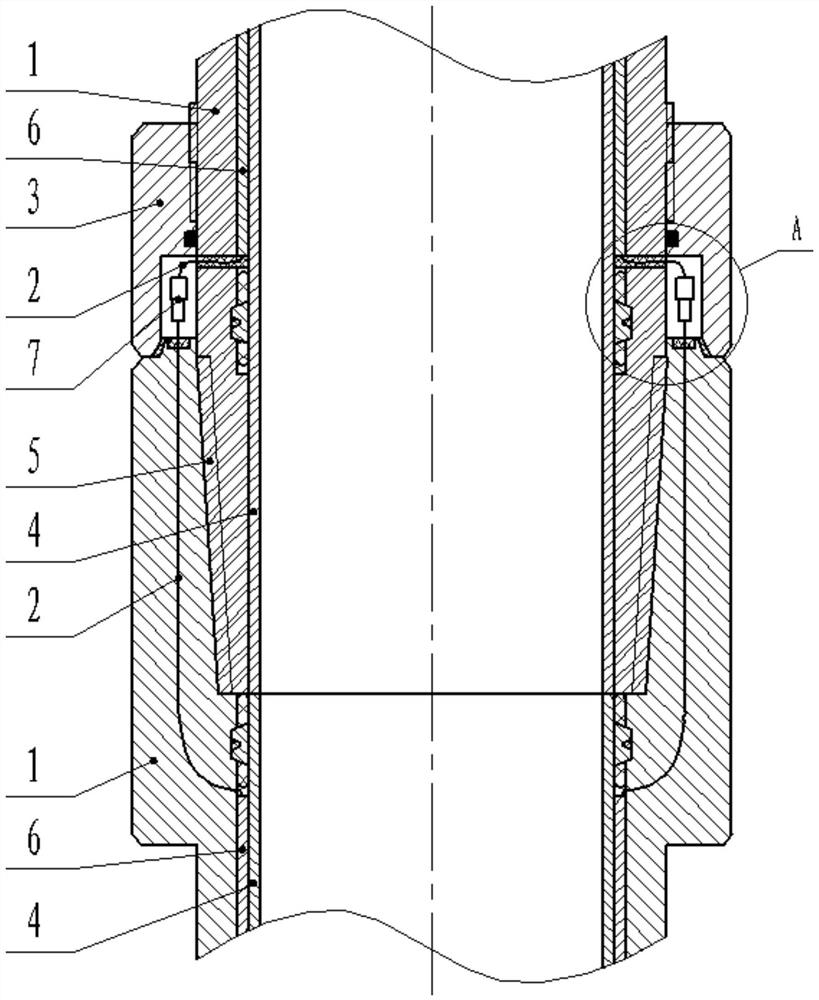

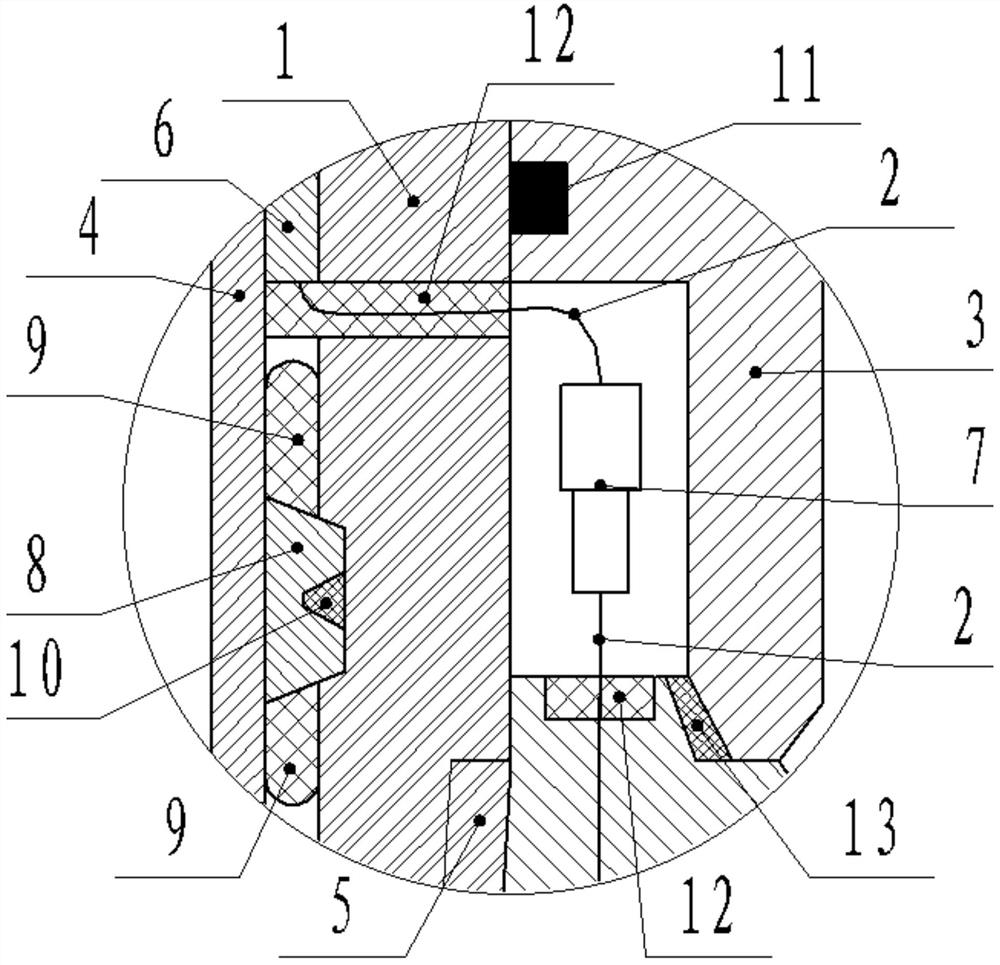

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as figure 1 As shown, the present invention includes an oil pipe body 1, the upper and lower ends of the oil pipe body 1 are respectively provided with an upper joint and a lower joint, and the inner side of the upper joint and the outer side of the lower joint are respectively processed with matching standard oil pipe sealing tapered threads 5, which are connected The two oil pipes are still connected through the conventional standard oil pipe sealing taper thread 5, which can fully guarantee the sealing performance and connection strength of the oil pipe joint, and is compatible with all conventional downhole tools.

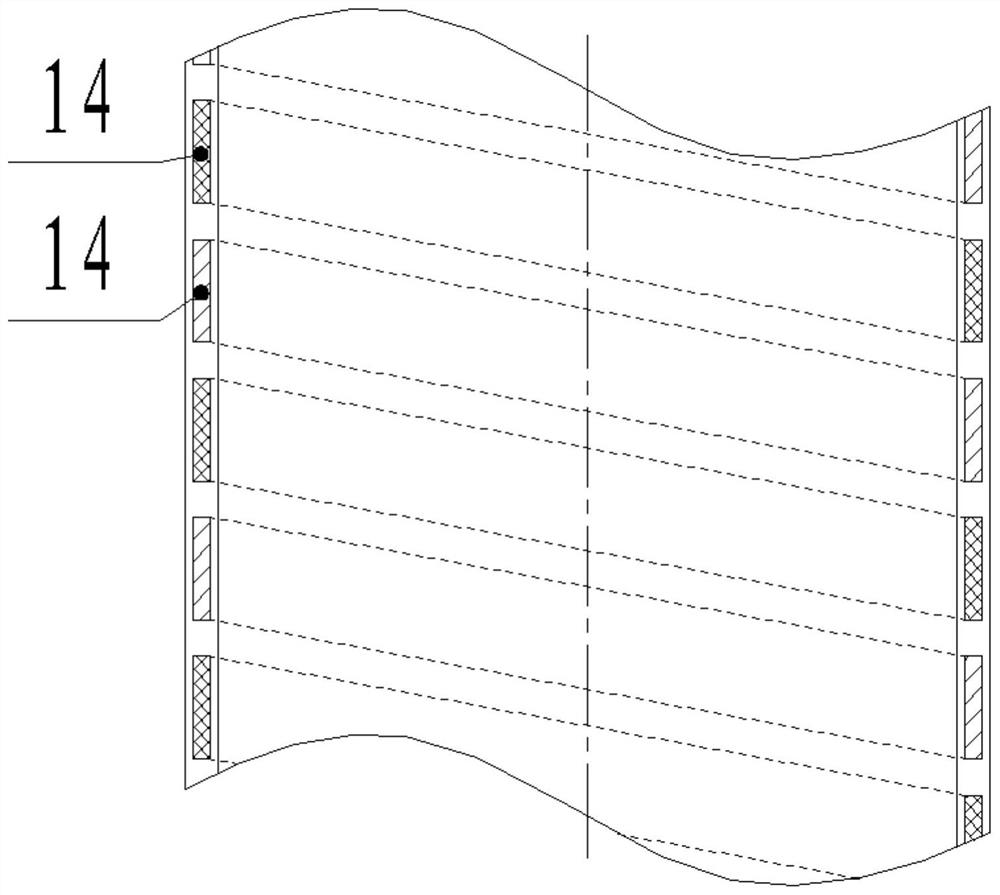

[0026] Such as figure 1 As shown, the inner side of the oil pipe body 1 is provided with an inner liner 4 made of stainless steel, the inner liner 4 extends upward to the lowermost end of the inner thread of the upper joint, and extends downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com