Filter element service life calculation method based on double engines

A filter element life and calculation method technology, applied in the field of water purifiers, can solve the problems of unchangeable time variable calculation model, poor reliability of results, and inaccurate results, so as to protect drinking water safety and prevent inaccurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

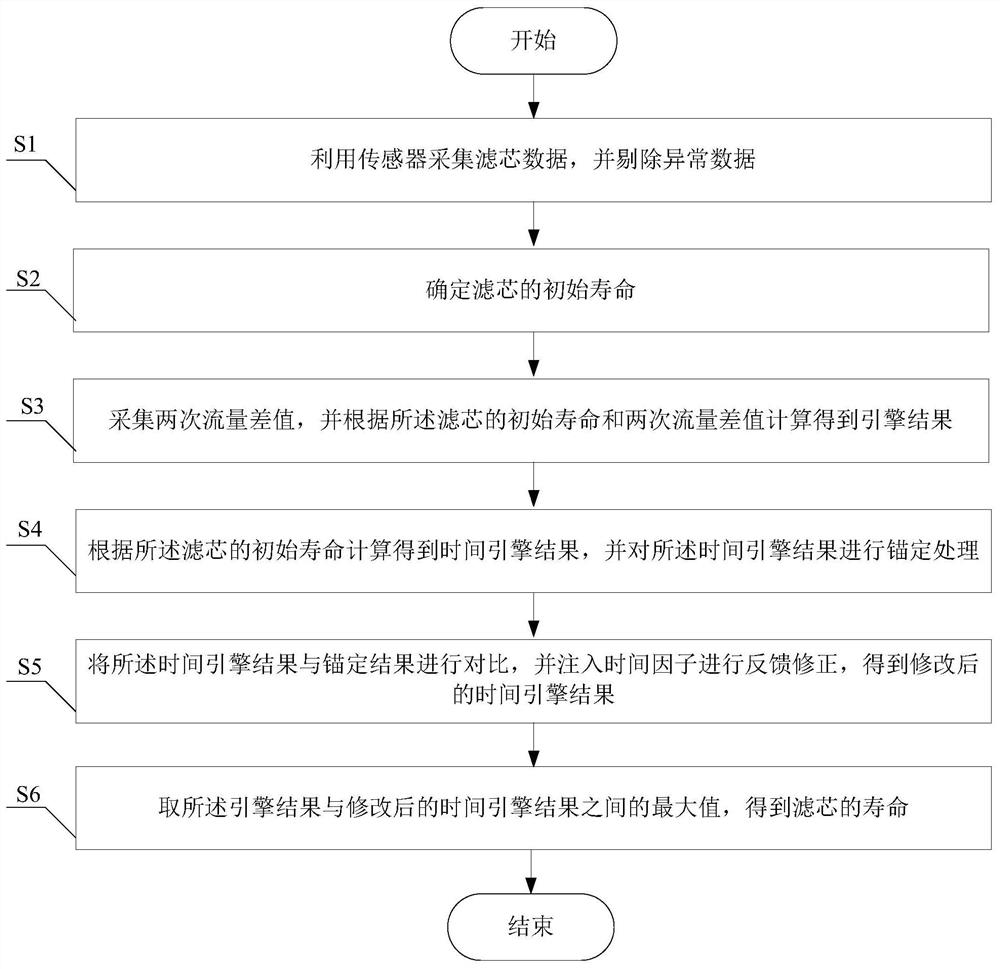

[0044] like figure 1 As shown, the present invention provides a method for calculating the life of a filter element based on dual engines, and its implementation method is as follows:

[0045] S1. Use the sensor to collect the data of the filter element, and eliminate the abnormal data of the filter element;

[0046] In this embodiment, the abnormal data removal includes: the absolute value of the flow rate exceeding the limit, the temperature and humidity data exceeding the limit, and the TDS sensor data exceeding the limit.

[0047] S2. Determine the initial life of the filter element, which is specifically:

[0048] Get the initial life of the filter element based on the typical service life of the filter element; or

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com