Multilayer core body and preparation method thereof

A core and porous layer technology, applied in the field of diapers, can solve the problems of thick diapers, lumps, faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

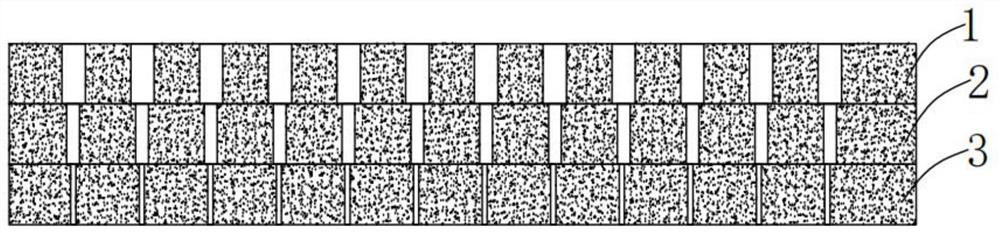

[0031] [Manufacturing method of multilayer core according to an embodiment of the present invention]

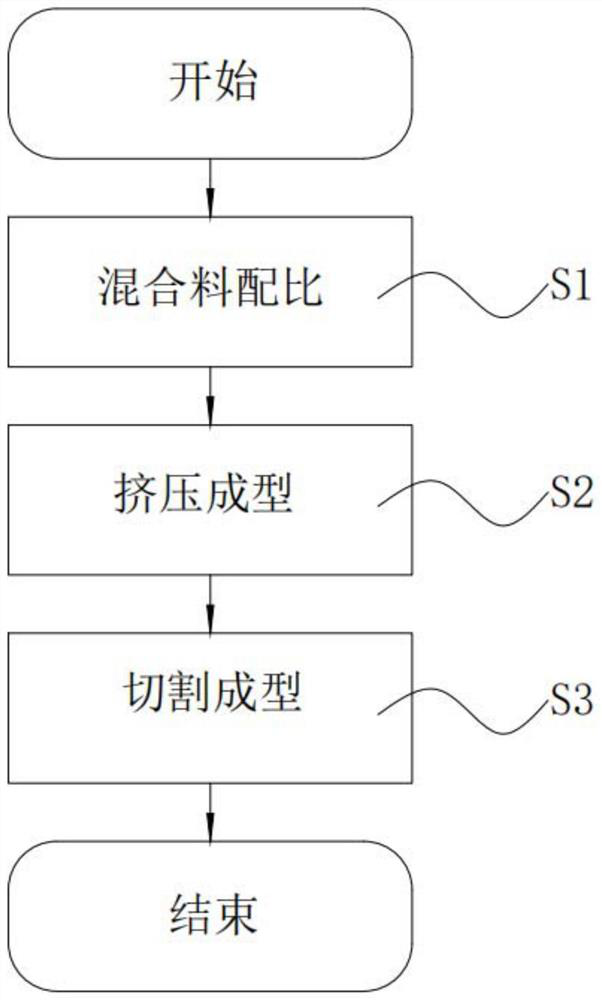

[0032] According to the preparation method of the multi-layer core body of the embodiment of the present invention, refer to figure 2 , the preparation method comprises:

[0033] Mixture proportioning step: proportioning the corresponding A mixture, B mixture and C mixture of the upper absorbent layer 1, the middle absorbent layer 2 and the lower absorbent layer 3;

[0034] Extrusion molding step: input the proportioned A mixture, B mixture and C mixture into the corresponding feed holes of the extrusion device respectively, and extrude and form through the extrusion device;

[0035] Cutting and molding step: cutting and separating the shaped cores to form several cores.

[0036] Preferably, the A mixture, the B mixture and the C mixture all include raw materials, pore-forming agents and water-retaining materials, and the upper absorbent layer 1, the middle absorbent layer...

Embodiment 1

[0045] Prepare the raw materials for preparing the core, NaHCO 3 , SAP powder, mix them and stir evenly to make A mixture, B mixture and C mixture, NaHCO in A mixture, B mixture and C mixture 3 The addition amount decreases sequentially, and the addition amount of SAP powder increases sequentially. The A mixture, the B mixture and the C mixture are respectively passed into the mixing chamber, and are transported to the multi-layer co-extrusion composite distributor through the corresponding feeding hole by the metering pump. Extruded through a slit die, finally foamed and matured to form upper absorbent layer 1, middle absorbent layer 2 and lower absorbent layer 3, and finally upper absorbent layer 1, middle absorbent layer 2 and lower absorbent layer 3 are bonded by hot melt adhesive Composite, and finally cut into cores.

Embodiment 2

[0047] Prepare the raw materials for preparing the core, NaHCO 3 , SAP powder, NaCl, mix them and stir evenly to make A mixture, B mixture and C mixture respectively, NaHCO in A mixture, B mixture and C mixture 3 The amount of addition decreases in turn, and the amount of SAP powder added in turn increases. The A mixture, B mixture and C mixture are respectively passed into the mixing chamber, and are transported to the multi-layer co-extrusion compound distributor through the corresponding feeding hole by the metering pump. Extruded through a slit die, finally foamed and matured to form upper absorbent layer 1, middle absorbent layer 2 and lower absorbent layer 3, and finally upper absorbent layer 1, middle absorbent layer 2 and lower absorbent layer 3 are bonded by hot melt adhesive Composite, and finally cut into cores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com