Mite-removing cleaning wet tissue and preparation method thereof

A technology for wet wipes and cleaning, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., and can solve the problems of no wet wipes and large skin irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

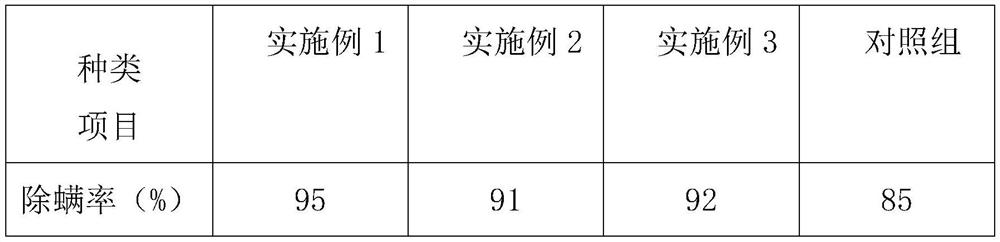

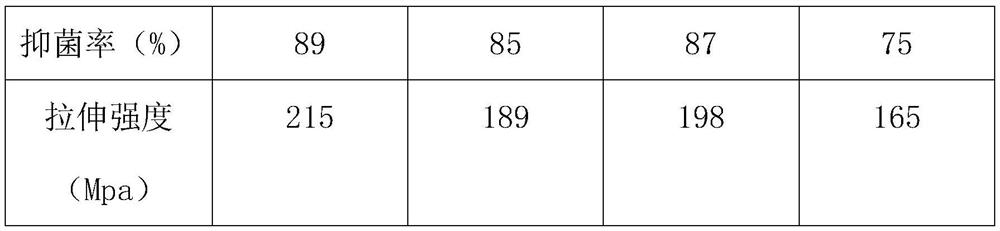

Examples

Embodiment 1

[0022] S1, the preparation of base cloth: choose 12 parts of polylactic acid fibers, 28 parts of cotton fibers, 12 parts of bamboo pulp fibers and 13 parts of wood pulp fibers, after mixing polylactic acid fibers, cotton fibers, bamboo pulp fibers and wood pulp fibers, pass The opener is used for loosening and breaking up, and the prepared mixed fiber is ready for use. The mixed fiber is sent to the carding machine for carding and diffusion, and then the carded mixed fiber is sent to the web-laying machine to obtain a composite fiber web, and the composite fiber web is transported into the main machine. The carding machine is used for carding to obtain the upper layer thin net and the lower layer thin net, which are transported to the heat-sealing forming device, and the composite non-woven fabric made after the heat-sealing operation is wound up, and the base fabric is obtained after cutting ;

[0023] S2, preparation of infusion: select 7 parts of wormwood leaves and 22 part...

Embodiment 2

[0026] S1, the preparation of base cloth: choose 10 parts of polylactic acid fiber, 20 parts of cotton fiber, 10 parts of bamboo pulp fiber and 10 parts of wood pulp fiber, after polylactic acid fiber, cotton fiber, bamboo pulp fiber and wood pulp fiber are mixed, pass The opener is used for loosening and breaking up, and the prepared mixed fiber is ready for use. The mixed fiber is sent to the carding machine for carding and diffusion, and then the carded mixed fiber is sent to the web-laying machine to obtain a composite fiber web, and the composite fiber web is transported into the main machine. The carding machine is used for carding to obtain the upper layer thin net and the lower layer thin net, which are transported to the heat-sealing forming device, and the composite non-woven fabric made after the heat-sealing operation is wound up, and the base fabric is obtained after cutting ;

[0027] S2, preparation of soaking solution: select 5 parts of wormwood leaves and 15 p...

Embodiment 3

[0030] S1, the preparation of base cloth: select 15 parts of polylactic acid fibers, 35 parts of cotton fibers, 15 parts of bamboo pulp fibers and 15 parts of wood pulp fibers, after mixing polylactic acid fibers, cotton fibers, bamboo pulp fibers and wood pulp fibers, pass The opener is used for loosening and breaking up, and the prepared mixed fiber is ready for use. The mixed fiber is sent to the carding machine for carding and diffusion, and then the carded mixed fiber is sent to the web-laying machine to obtain a composite fiber web, and the composite fiber web is transported into the main machine. The carding machine is used for carding to obtain the upper layer thin net and the lower layer thin net, which are transported to the heat-sealing forming device, and the composite non-woven fabric made after the heat-sealing operation is wound up, and the base fabric is obtained after cutting ;

[0031] S2, preparation of soaking liquid: select 10 parts of wormwood leaves and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com