Welding equipment for 5G signal element machining

A technology for signal components and welding equipment, applied in the field of welding equipment for 5G signal component processing, can solve the problems of inconvenience, affect welding quality, and cannot guarantee the complete level of signal components, and achieve convenient welding, improve welding quality, and prevent upward rebound. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

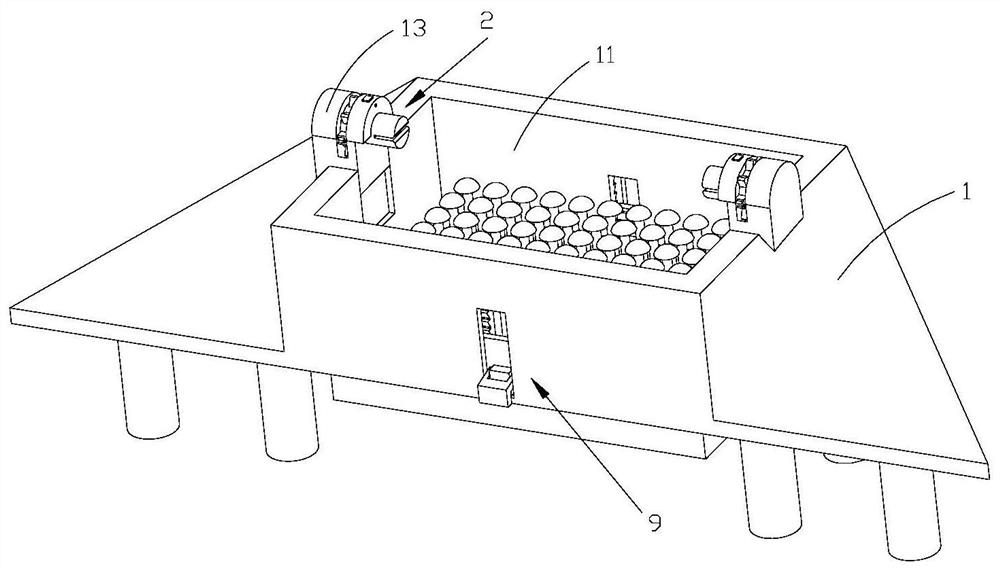

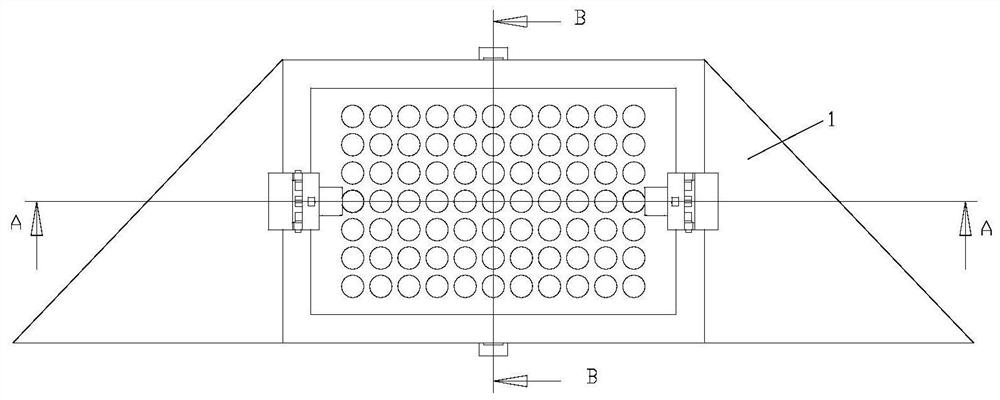

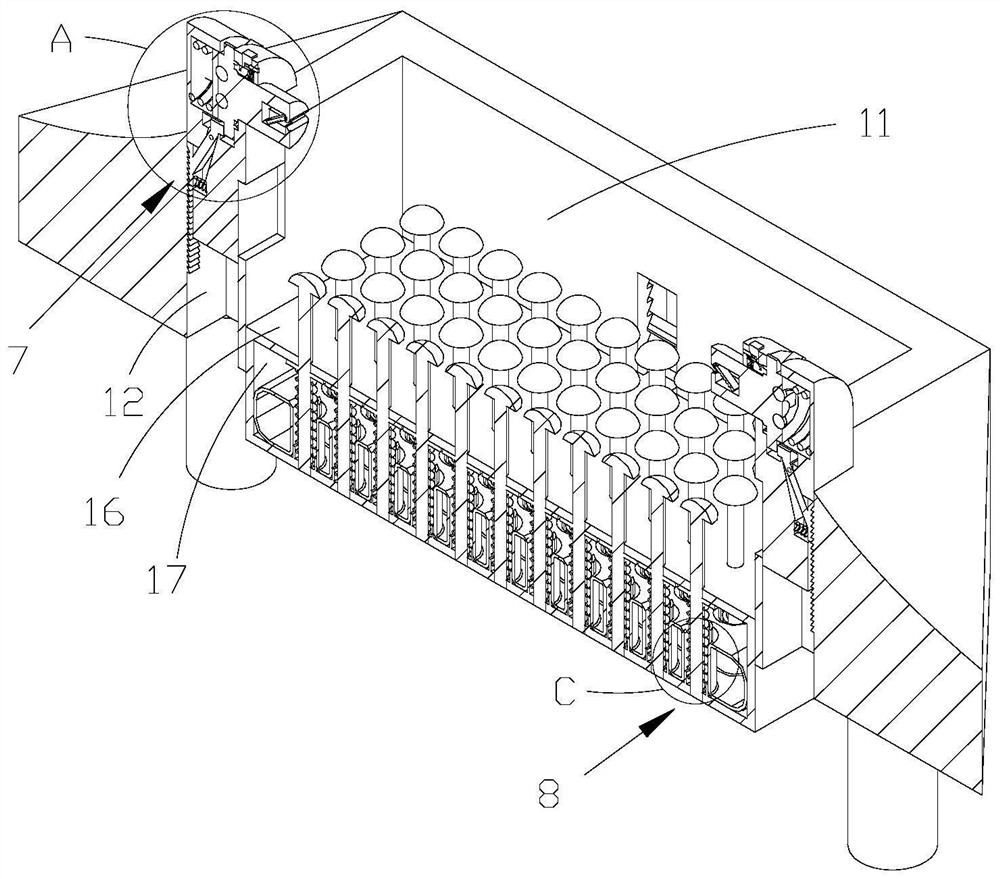

[0033] Such as Figure 1-13 As shown, a welding device for processing 5G signal components, including a base 1, a processing groove 11, a through groove 12, a slider 13, a first fixed block 14, a return spring 15, a clamping part 2, a first limit Component 7, extrusion plate 16, extrusion cavity 17, multiple extrusion components 8, second limiting component 9; processing groove 11 is provided on the base 1, through groove 12 is symmetrically provided on the base 1, The slide block 13 is respectively arranged on the said through groove 12 movable up and down, and the first fixed block 14 is symmetrically arranged on the said slide block 13, and the two ends of the back-mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com