Inspection robot system for wind turbine generator

A technology for inspecting robots and wind turbines, applied in manipulators, program-controlled robots, manufacturing tools, etc., can solve problems such as the inability to meet the real-time monitoring of wind turbines, the failure to monitor important components of wind turbines, and the daily maintenance requirements, etc. The effect of light weight, solving space limitation problems, and simple path planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

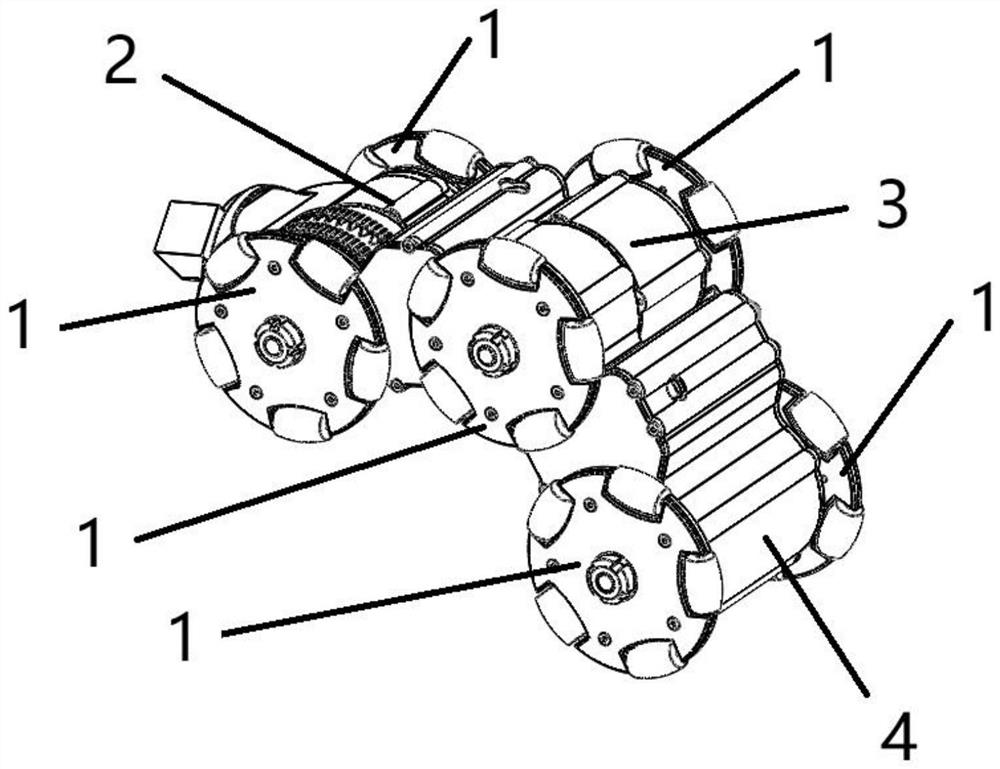

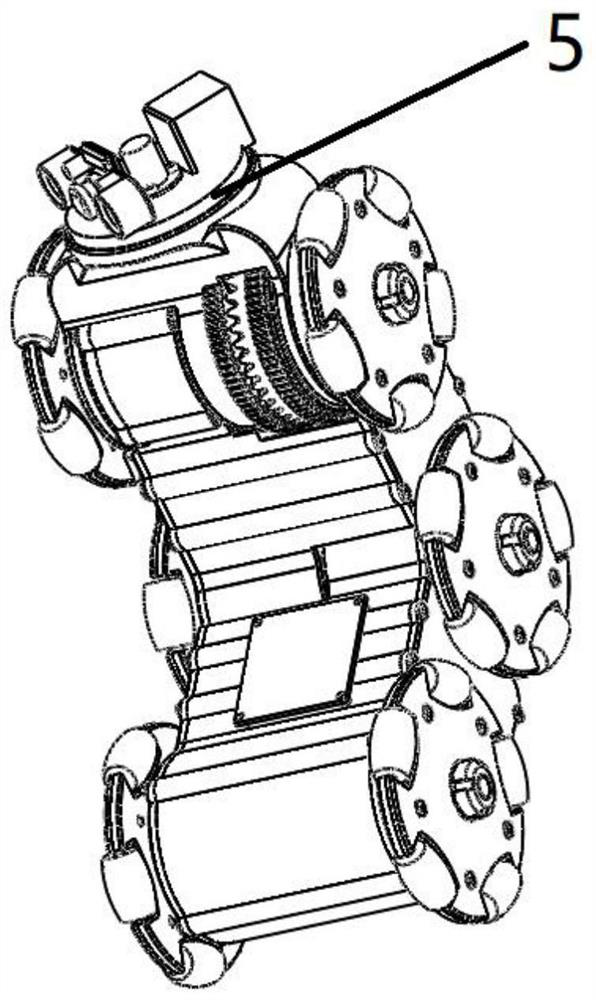

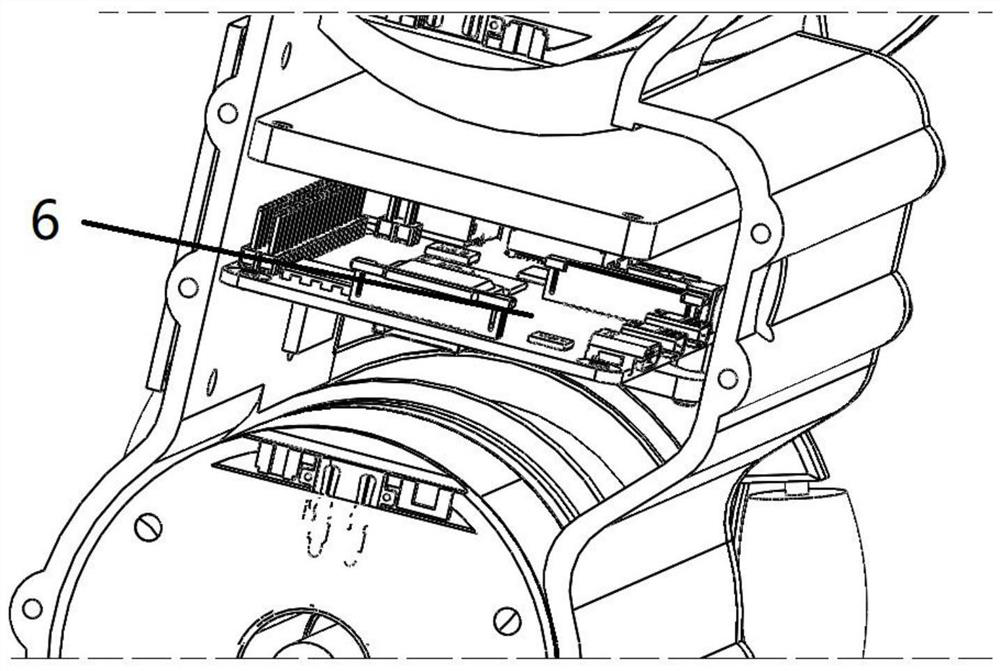

[0028] This embodiment provides a wind turbine inspection robot system, including a nacelle intelligent inspection robot, a robot cabin cabinet, a robot tower bottom cabinet, and an intelligent inspection robot remote monitoring station;

[0029] The engine room intelligent inspection robot is equipped with monitoring sensors, which are used to travel in the engine room according to the prescribed route, and inspect the monitoring points inside the engine room through the equipped monitoring sensors; monitoring sensors include infrared night vision cameras, thermal imaging cameras, smoke sensors, sound Sensors, temperature and humidity sensors; the monitoring points inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com