Car roof assembly and vehicle

A technology of assembly and car body, applied in the field of roof assembly and vehicles, can solve the problems of low lightweight level, high production cost and low production efficiency of all-stainless steel roof, and achieve convenient lightweight design, installation and disassembly operations. Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In the prior art, the low floor trail usually uses all-aluminum alloy roof or all stainless steel roofs. However, the entire aluminum alloy car is formed by welding of aluminum profiles, not only high in raw material, but also high-aluminum mold is high, but also high welding requirements; low production efficiency; the top quality of all stainless steel vehicles, high center, leading to light weight Low level, and the vehicle is easily unstable, and the safety is poor.

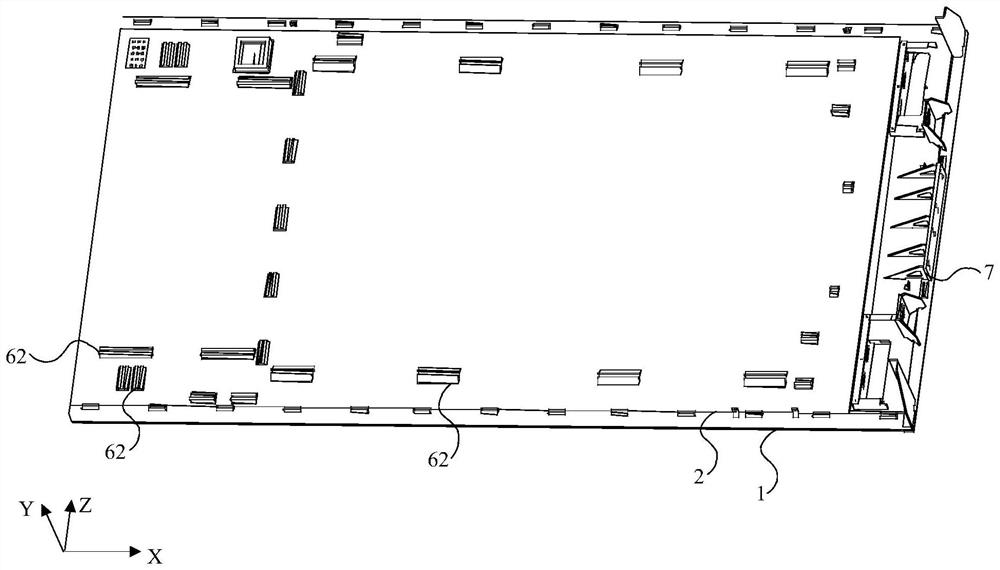

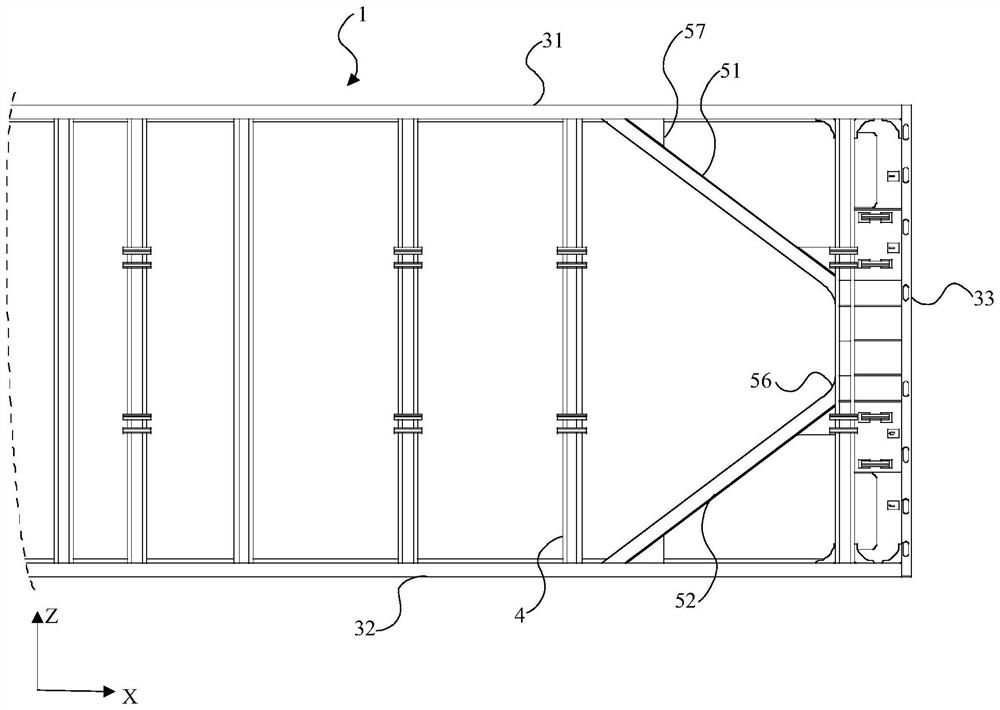

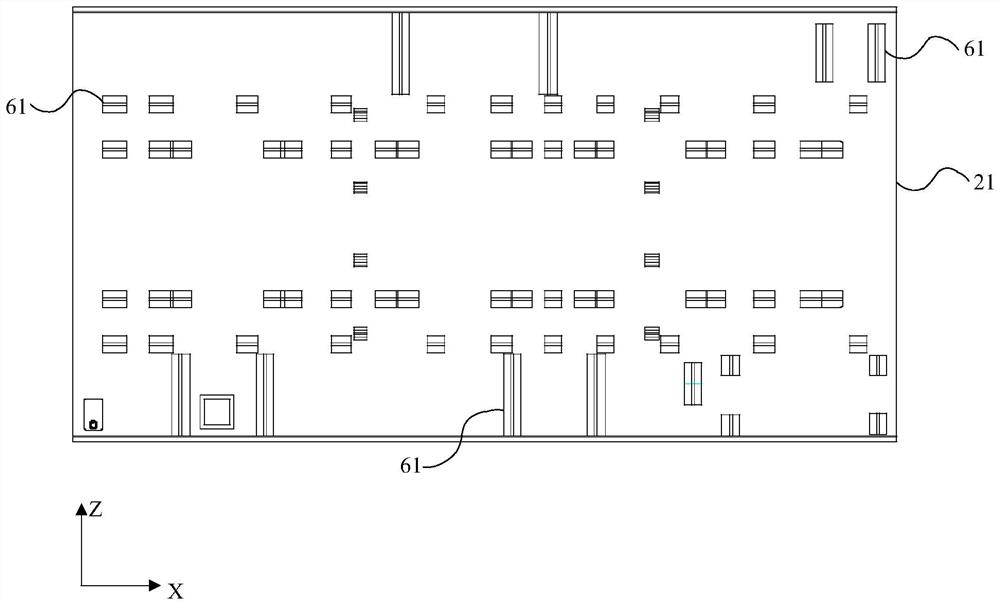

[0036]In view of this, the present invention provides a roof assembly and a vehicle, by adopting a roof frame and a top plate assembly, wherein the steel skeleton includes a frame and a plurality of vertical beams connected to the frame. The top plate assembly includes a first aluminum plate layer, a second aluminum sheet layer, and a sandwich layer bonded between the first aluminum plate layer and the second aluminum sheet, but also the structure is simple, it is advantageous to reduce production cost, improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com