Rotary bearing mechanism and engine split assembly tray

A technology of carrying mechanism and carrying plate, which is applied in the direction of packaging, transportation and packaging, rigid containers, etc., can solve the problems of reducing production efficiency, increasing labor costs, and difficult operations for operators, so as to avoid overturning, prevent tilting, and optimize rotation stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

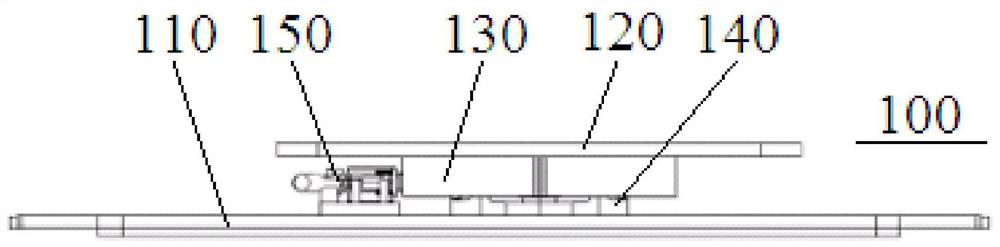

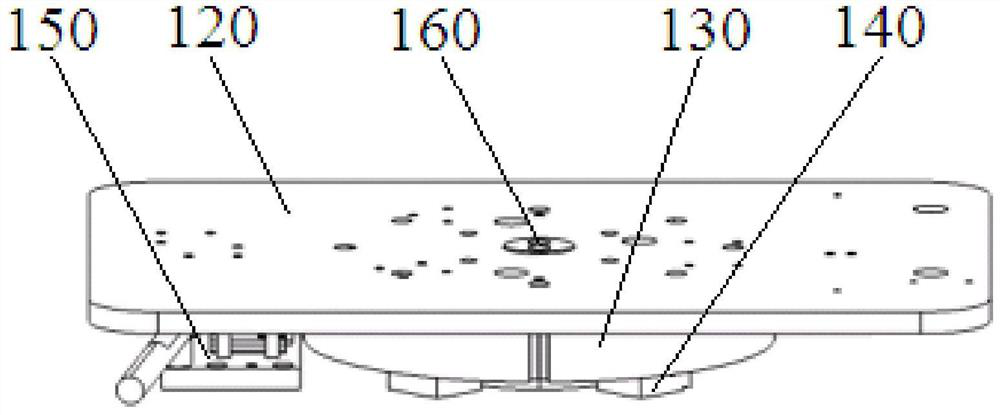

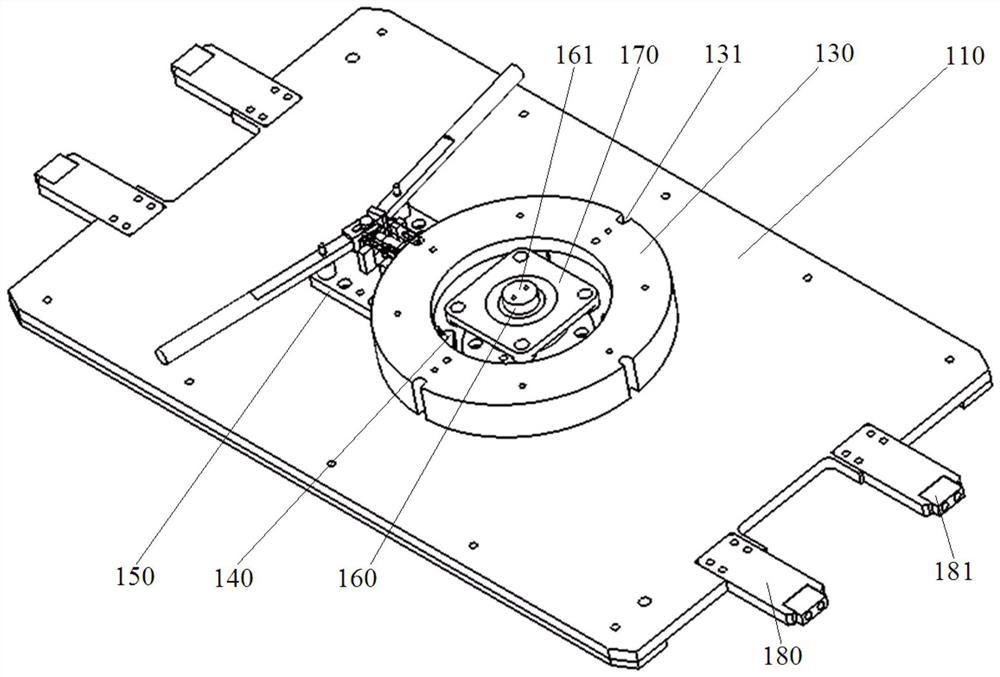

[0043] An embodiment of the present invention provides a rotating bearing mechanism 100, the structure of which is as follows Figure 1 to Figure 3 As shown, it specifically includes a tray base 110, a rotating shaft 160, a bearing plate 120, a rotating bearing plate 130 and more than three load bearing components 140. The tray base 110, load bearing components 140, rotating bearing plate 130 and bearing plate 120 Arranged sequentially from bottom to top to form a multi-layer bearing structure, the rotating shaft 160 is rotationally connected to the tray base 110 or the loading plate 120, and the rotating loading plate 130 is fixedly connected to the loading plate 120, and the rotating shaft 160 connects the loading plate 120, the tray base 110 to the The rotating bearing plate 130 is connected as a bearing body to realize the functions of load-bearing and stably supporting the engine and the transmission. The rotating bearing plate 130 is set on a plurality of load-bearing co...

Embodiment 2

[0057] Based on the same inventive concept, this embodiment provides an engine sub-package tray, its structure is as follows Figure 8 with Figure 9 As shown, the rotary bearing mechanism 100 including the engine support assembly, the transmission support base 230 and the above-mentioned embodiment 1, the engine support assembly and the transmission support base 230 are installed on the bearing plate 120 of the rotation bearing mechanism 100, the specific details of the rotation bearing mechanism 100 Refer to Embodiment 1 for the structure, and details are not repeated here.

[0058] see Figure 8 with Figure 11 , in this embodiment, the engine support assembly includes an engine support base 220 and an engine support module 210, the engine support base 220 is installed on the carrier plate 120 through a support column 250, and the engine support module 210 is detachably installed on the engine support base 220, The engine support module 210 is special-purpose. The size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com