Full-automatic towel feeding device

A technology of feeding device and towel machine, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., which can solve the problems of insufficient flatness of towels, low operation efficiency, and high product failure rate, so as to improve operation efficiency and ensure smoothness Degree, the effect of improving the product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

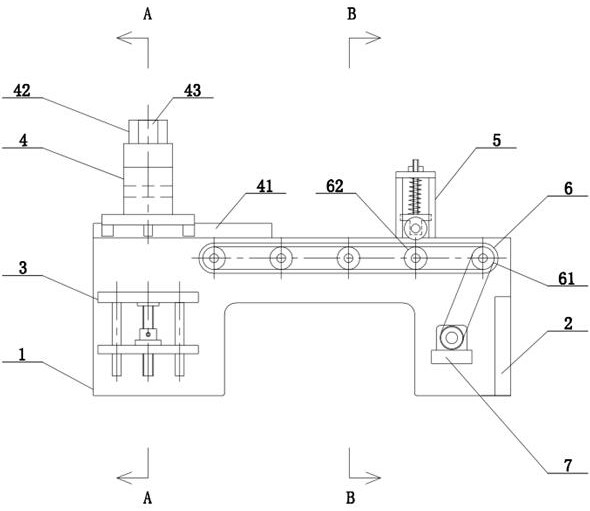

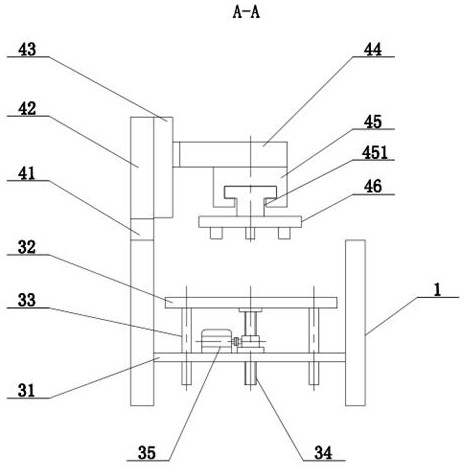

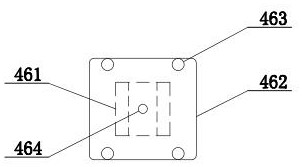

[0021] see Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: it includes two side plates 1, connecting plate 2, material lifting mechanism 3, feeding mechanism 4, flattening mechanism 5, transmission mechanism 6, driving mechanism 7; connecting plate 2 It is arranged between the two side plates 1; the material lifting mechanism 3 includes a bottom plate 31, a lifting plate 32, a guide shaft 33, a turbine screw lifter 34, and a first drive motor 35; the bottom plate 31 is arranged on the two side plates 1 between, and the bottom plate 31 is located on the left side of the side plate 1; the guide shafts 33 are arranged symmetrically at the bottom of the lift plate 32 in groups of two; wherein, the guide shafts 33 pass through the base plate 31, and then the top of the guide shaft 33 and the lift plate 32 Connection; the connection relationship between the guide shaft 33 and the base plate 31 is a sliding connection; the turbine screw lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com