Two-section type lifting deceleration strip

A deceleration belt, two-stage technology, applied in the field of two-stage lifting deceleration belt, can solve the problem of low function of deceleration belt, achieve fast response, good lifting function, stable and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

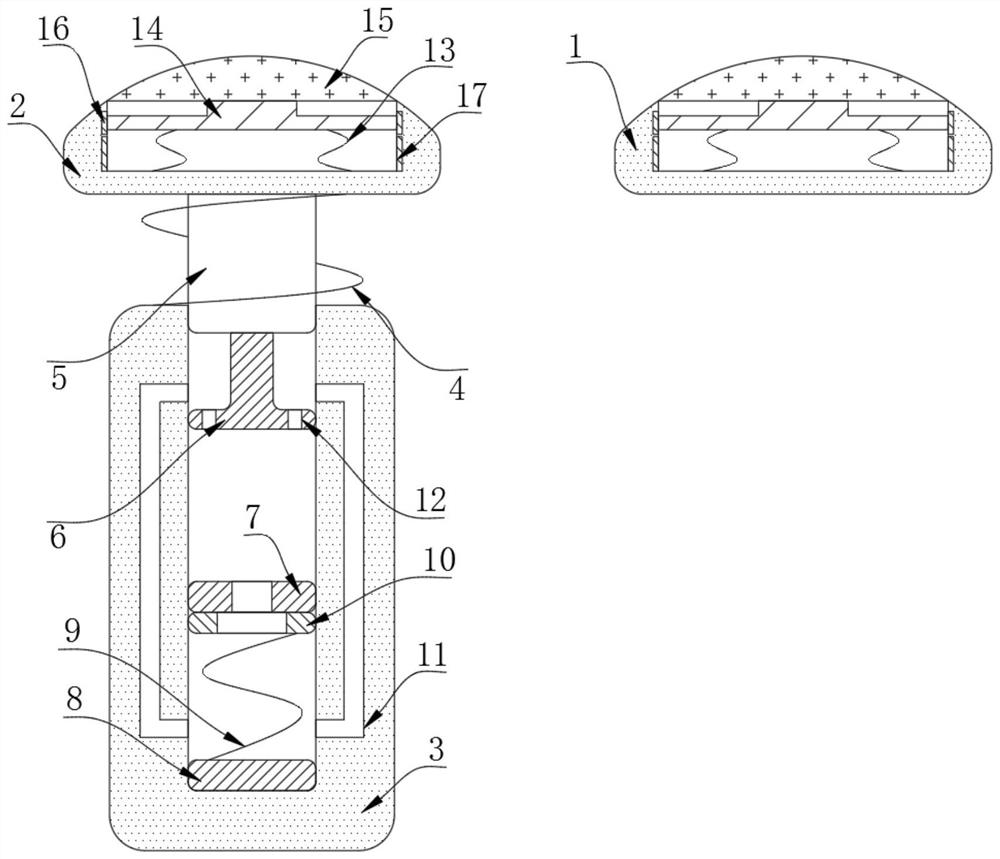

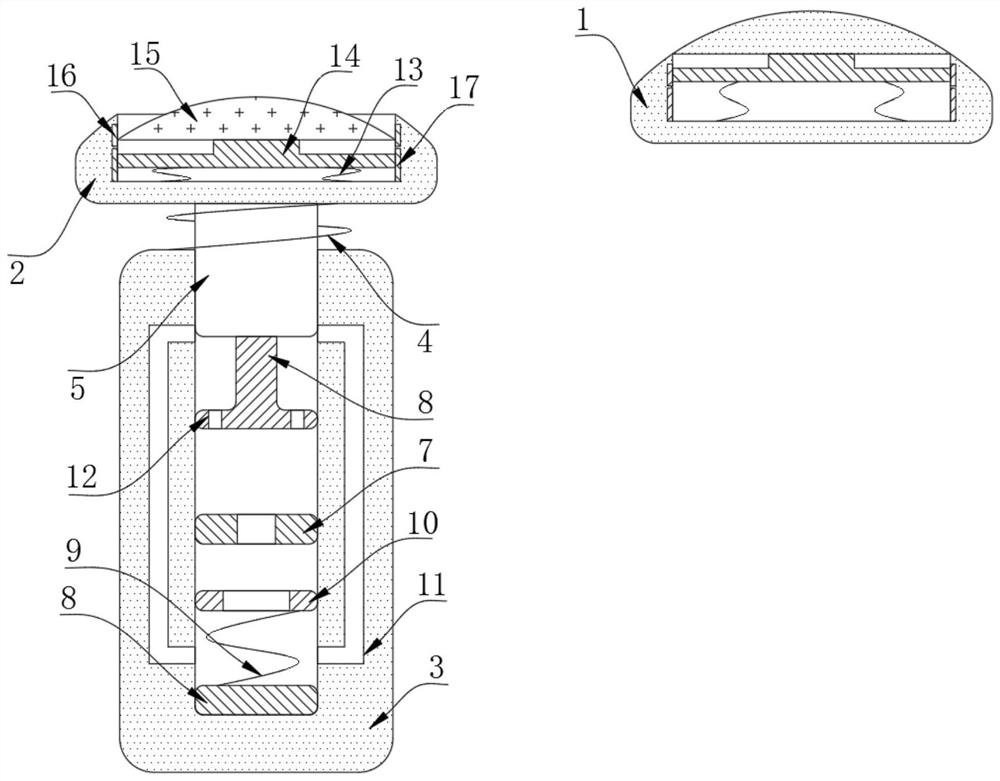

[0021] refer to Figure 1-2 , a two-stage lifting deceleration belt, including a front end 1, a rear end 2 and a buried column 3, the interior of the front end 1 and the rear end 2 are equipped with a starting mechanism, and the upper end of the buried column 3 is connected to the rear end 2 through a return spring 4 , the bottom of the rear end 2 is fixed with a sliding rod 5 that is sealingly and slidingly connected with the inner wall of the buried column 3, and the bottom of the sliding rod 5 is fixed with a push plate 6 that is sealingly and slidingly connected with the inner wall of the buried column 3, and the inner wall of the buried column 3 is fixed with a spacer ring 7. The bottom of the buried column 3 is provided with a pushback mechanism.

[0022] The push-back mechanism includes a suction block 8 fixed on the bottom of the buried column 3, the suction block 8 is an electromagnet, the upper end of the suction block 8 is connected with a push-back ring 10 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com