Mixed supporting system for steel structure integral lifting construction

An overall lifting and mixed support technology, which is applied in building construction, building material processing, construction, etc., can solve problems such as failure to meet the support coverage requirements of lifting points, and achieve small deformation, short force transmission path, and direct force transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

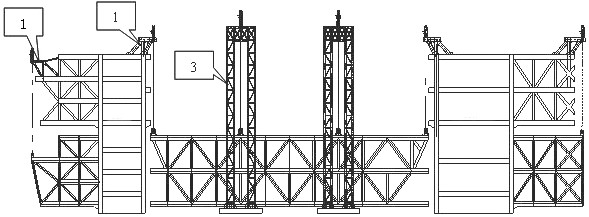

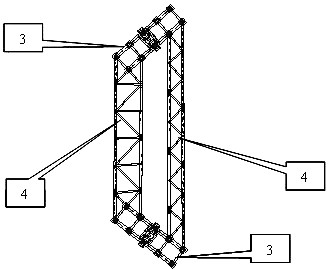

[0018] Such as figure 1 , 2 Shown: A hybrid support system for the overall lifting construction of steel structures. After determining the layout points of the lifting points, based on careful structural calculations, through the original structure itself, outside the original structure, and the extension structure of the original structure A large number of different types of support structures are arranged on the ground to build a complete lifting hybrid support system, which enables the lifting of extremely complex structures. The specific implementation method is as follows:

[0019] A hybrid support system for overall lifting construction of a steel structure is characterized in that it includes the following steps:

[0020] Step 1: According to the structural characteristics, analyze the force system of the original structure, and determine the location of the lifting points according to the number of beams or columns that need to be lifted;

[0021] Step 2: Classify ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com