Pressing device for planar antenna and layout method

A technology of a pressing device and a plane antenna, which is applied in the field of aerospace vehicles, can solve the problems of difficulty in ensuring accuracy, increased thickness of the antenna, and increased release stroke of the pressing rod, so as to solve the interference problem, improve the reliability, and reduce the processing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

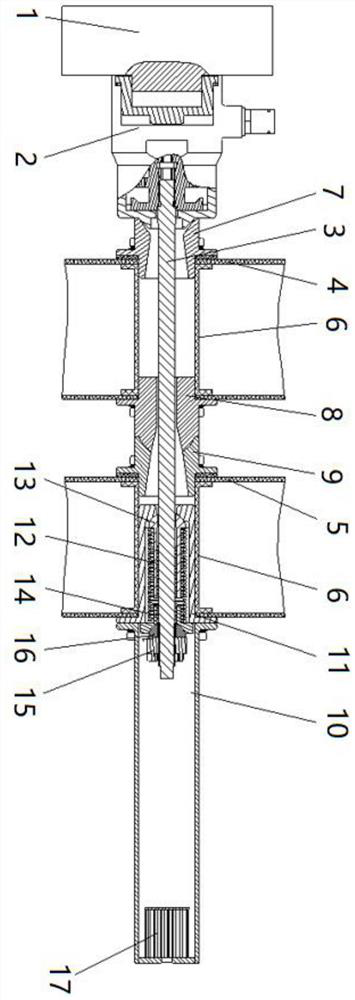

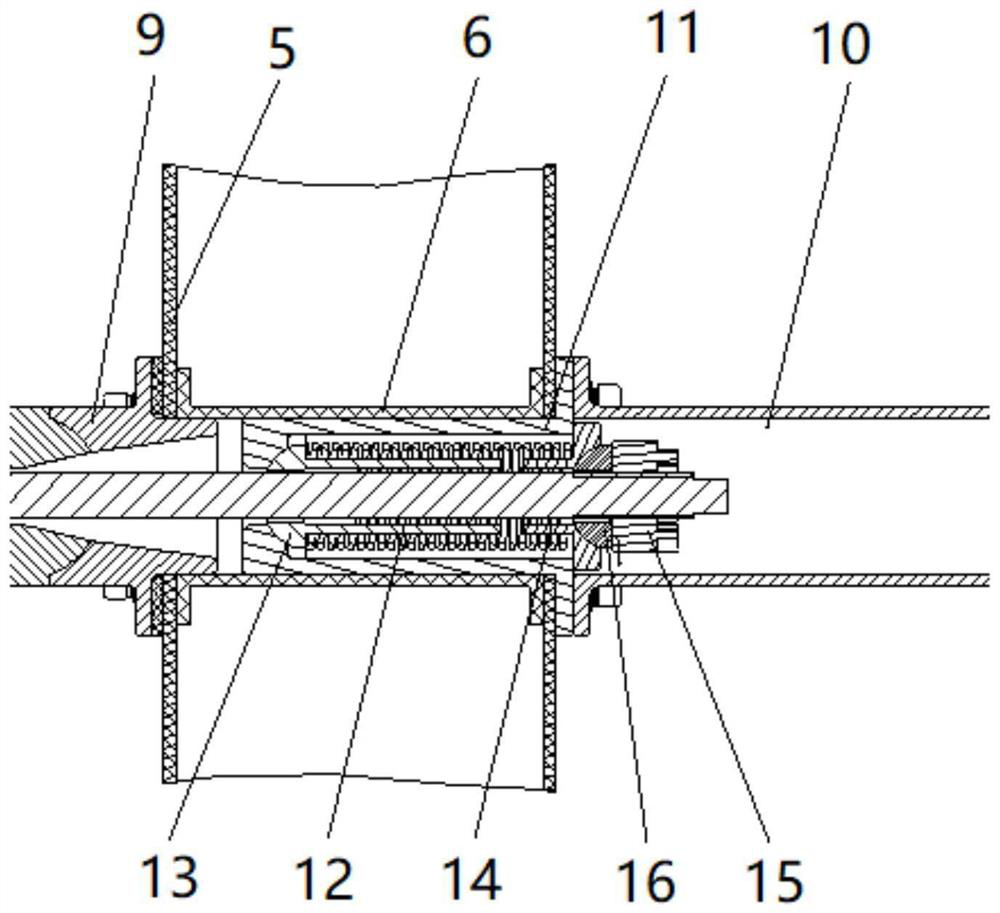

[0045] see figure 1 and figure 2 , the present embodiment provides a pressing device 01 facing a planar antenna, which is used for pressing two adjacent antenna boards. Among the two adjacent antenna boards, the one close to the satellite platform 1 is the first antenna board 4, and the other is the first antenna board 4. The second antenna board 5 , the first antenna board 4 and the second antenna board 5 are all provided with through holes for passing the pressing device 01 .

[0046] The pressing device 01 includes a first connecting piece, a second connecting piece, a third connecting piece, a force applying sleeve 11, a spring 12, a fastener, a pressing rod 3, an outer sleeve 10 and a lock fixed to the satellite platform 1 Tight parts. According to the distance from the satellite platform 1 from near to far, it is the locking part, the first connecting part, the first antenna board 4, the second connecting part, the third connecting part, the second antenna board 5 and...

Embodiment 2

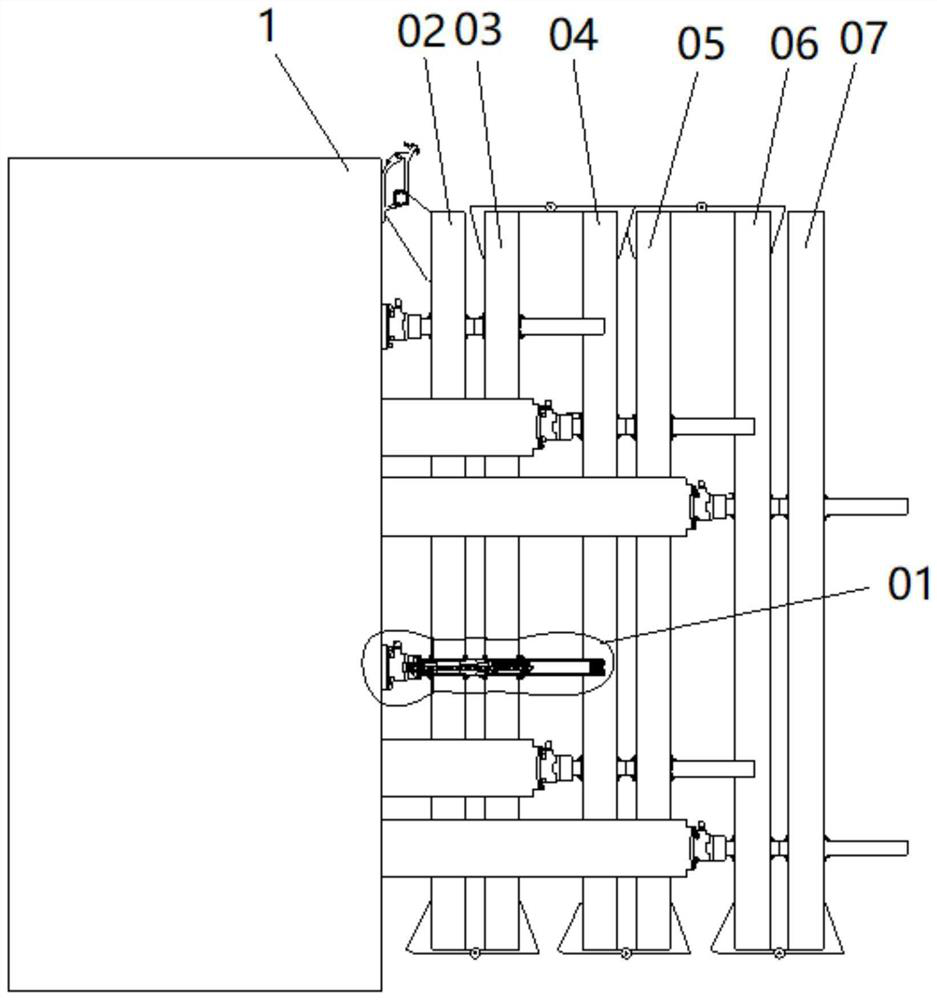

[0061] see image 3 , this embodiment provides a planar antenna-oriented pressing device layout method based on Embodiment 1.

[0062] According to distance from the satellite platform 1, every two antenna boards are divided into one group of antenna board groups from near to far, and the two antenna boards in each group of antenna board groups adopt the pressing device 01 facing the planar antenna as in Embodiment 1. Compression, all the compression devices 01 cooperate with each other to compress all the antenna boards to the folded state.

[0063] Taking six antenna boards as an example, they are antenna board A 02, antenna board B 03, antenna board C 04, antenna board D 05, antenna board E 06 and antenna board F 07 according to the distance from satellite platform 1 from near to far. The six antenna boards are divided into three layers, antenna board A02 and antenna board B 03 are a group of antenna boards, antenna board C 04 and antenna board D 05 are a group of antenna ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com