Zipper roller shutter structure

A rolling shutter structure and zipper technology, which is applied to building components, building structures, door/window protection devices, etc., can solve the problems that the skylight cannot be used for horizontal operation, the curtain wall structure cannot be used, and the curtain is easy to wrinkle and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

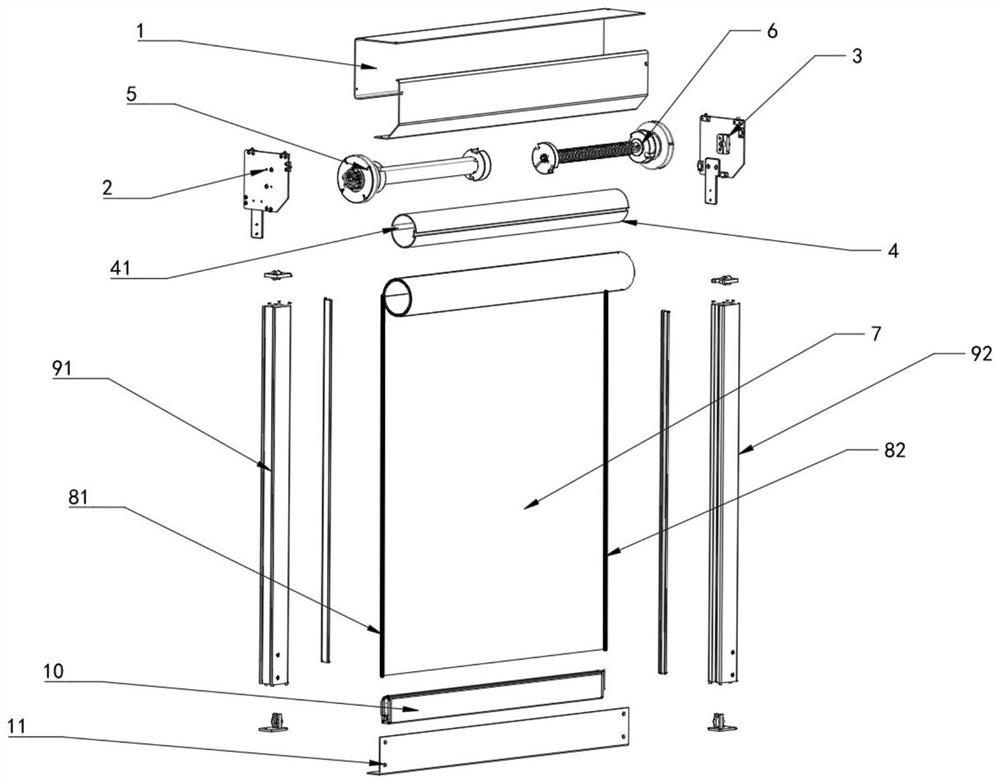

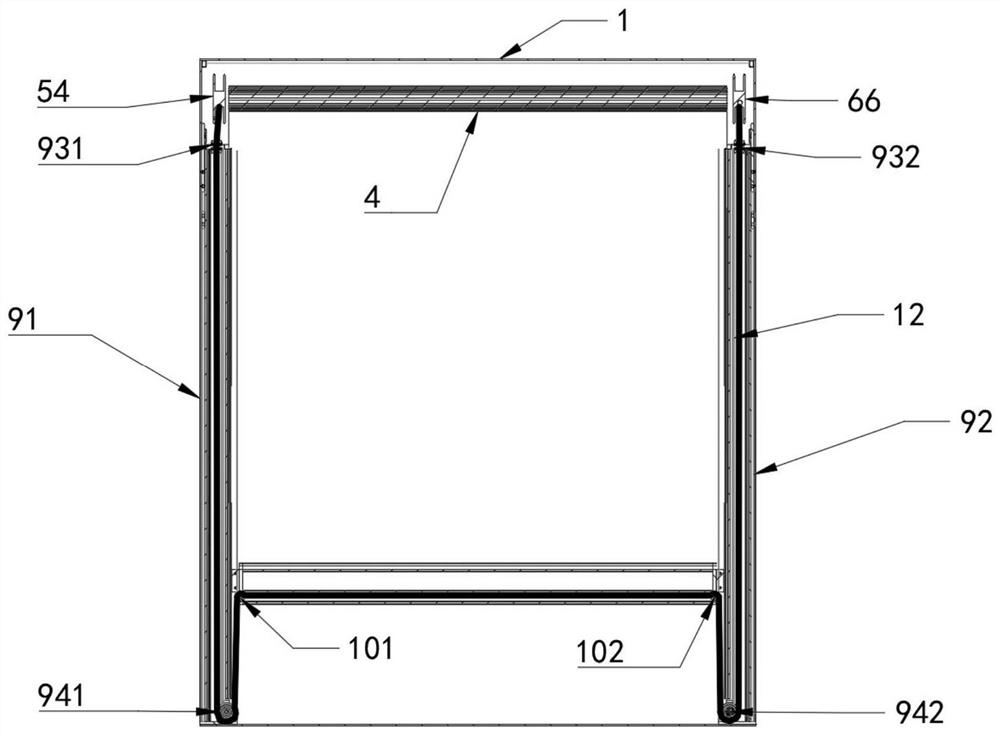

[0021] Depend on figure 1 As shown, the zipper roller blind structure of the present invention includes a casing 1 composed of a "7"-shaped upper casing and an "L"-shaped lower casing that cooperate with each other. The left and right ends of the casing 1 are respectively fixedly connected with a left mounting plate 2 and a right mounting plate 3. The casing 1 is provided with a reel 4 .

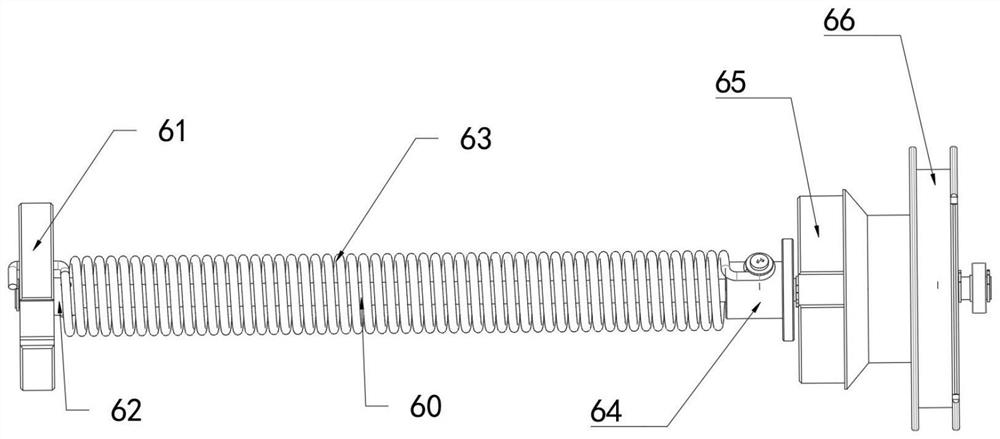

[0022] Reel 4 is provided with motor assembly 5, torsion spring assembly 6, and motor assembly 5 is inserted in the reel 4 from the left end of reel 4, and torsion spring assembly 6 is inserted in the reel 4 from the right end of reel 4.

[0023] The inner wall of the drum 4 has axially extending ribs 41 . The outer wall of the reel 4 is wound with a cord 7. The left and right edges of the cord 7 are respectively welded with a left slide fastener 81 and a right slide fastener 82. The left and right sides of the cord 7 are respectively provided with a left rail assembly 91 and a right rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com