A centrifugal fan collector with double arc profile

A centrifugal fan and current collector technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the few problems mentioned by the current collector, achieve improved efficiency, improve aerodynamic performance, and improve fan efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

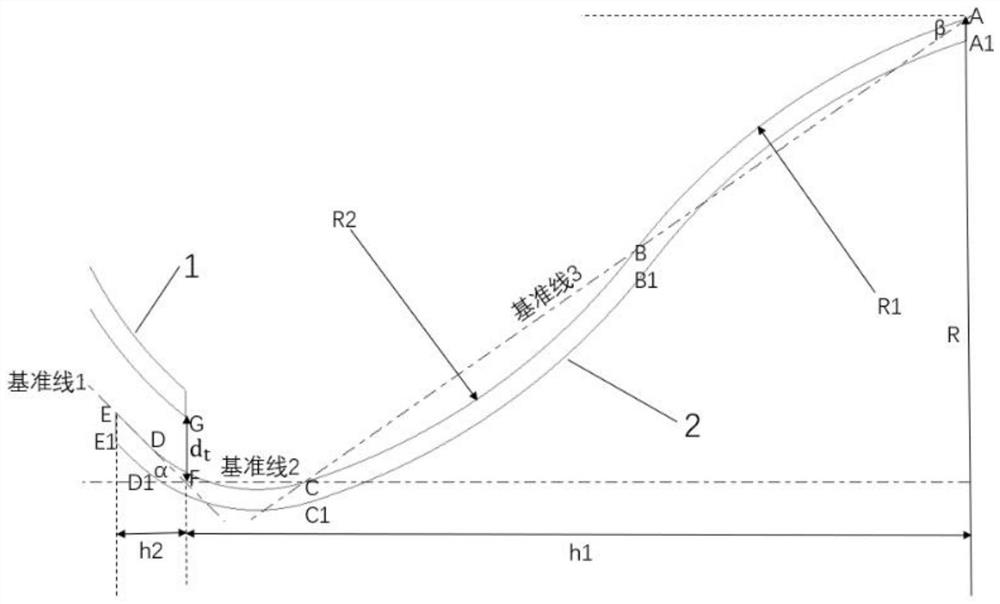

[0060] A kind of current collector design method for centrifugal fan of the present invention, specifically comprises the following steps:

[0061] Step 1, determine three baselines, the specific process is as follows:

[0062] Step 1.1, first determine the position of point A;

[0063] Such as figure 1 As shown, the radial distance from point A to the impeller rotation axis is R, and the axial distance from the impeller inlet end face is h1, and the position of point A can be determined according to R and h1;

[0064] In step 1.1, R and h1 are determined by the following formulas (1), (2):

[0065] R=(0.5)D out (1);

[0066] h1=(0.302)D out (2);

[0067] Among them, D out is the outer diameter of the impeller;

[0068] More preferably, R=0.5D out =250mm, h1=0.302D out =151mm, where D out = 500mm.

[0069] Step 1.2, determine the position of point F;

[0070] The radial distance between point F and point G on the inner wall surface of the impeller front disc 1 i...

example 2

[0090] Under different working conditions of the fan, on the basis of Example 1, keep R, h1, h2 unchanged, keep the three points of A, B, and C fixed, and change R1=R2=0.80*h1=120mm, that is, double circle The length and position of the arc chord remain unchanged, the radius of the arc is reduced, and the curvature of the double-arc line is increased. Follow the steps in Example 1 to draw the current collector line, and design a matching volute according to the changed current collector bus. Shell size parameters. Compared with Example 1, the radian of the double-arc profile line in Example 2 is significantly increased, which makes the angle between the airflow direction at the inlet and the collector profile line larger. Compared with Example 1, the curvature of the inlet section AB of the double-arc profile line increases. Small flow conditions are likely to cause the airflow to collide with the wall of the collector to form a vortex, which reduces the gentleness of the airf...

example 3

[0092] Under different working conditions of the fan, on the basis of Example 1, keep R, h1, h2 unchanged, keep the three points of A, B, and C fixed, and change R1=R2=0.90*h1=136mm, that is, double circle The length and position of the arc chord remain unchanged, the radius of the arc is increased, and the curvature of the double-arc line is reduced. Follow the steps in Example 1 to draw the current collector line, and design a matching one according to the changed current collector bus. Volute size parameters. Compared with Example 1, the radian of the double-arc line in Example 3 is reduced, and the airflow direction change angle is increased, which weakens the ability of the double-arc line to reduce the flow separation at the fan inlet, but compared with the prototype, the air flow is stable Enhanced performance, more suitable for small flow conditions.

[0093] Table 1 shows the experimental test data of the centrifugal fan with double-arc-shaped line collectors in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com