Gap coating valve and gap coating device

A gap and valve distribution technology, which is applied in the direction of valve device, device for coating liquid on the surface, valve operation/release device, etc., can solve problems such as uneven coating thickness, affecting coating quality, and easy blocking of slurry , to achieve the effect of improving coating uniformity, easy adjustment, and not easy to flow delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be described below in conjunction with the drawings in the embodiments of the present application.

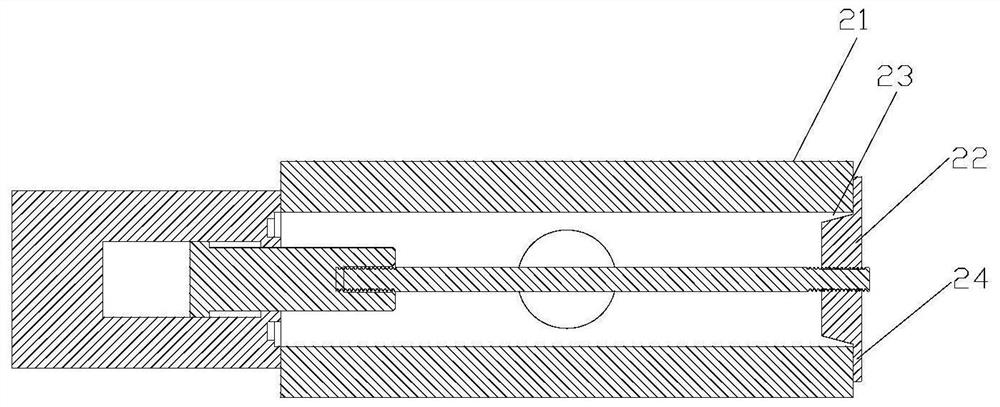

[0032] figure 2 It is a schematic cross-sectional structure diagram of a gap coating valve in the prior art. see figure 2 , the existing gap coating valve includes a valve core 22 and a valve body 21 that accommodates the valve core 22, the valve body 21 is provided with a valve port 23, and the valve core 22 slides relative to the valve body 21 in the direction of extension of the valve body 21 to Open or close valve port 23.

[0033] The spool 22 has a baffle 24. When the spool 22 closes the valve port 23 of the valve body 21, the plate surface of the baffle 24 is in sealing fit with the end surface where the valve port 23 is located, that is, when the spool 200 closes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com