Panel type angle stop valve for oxygen cabin

An angle globe valve, oxygen chamber technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of difficult to meet installation requirements, inconvenient installation and maintenance, and high maintenance costs, so as to reduce adverse effects and reduce maintenance costs. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

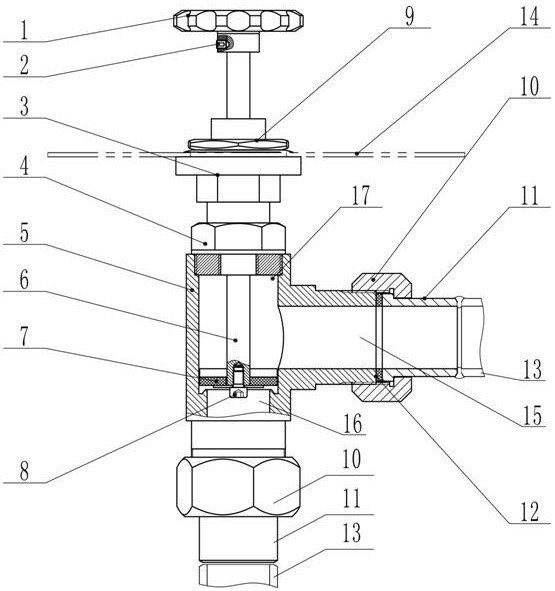

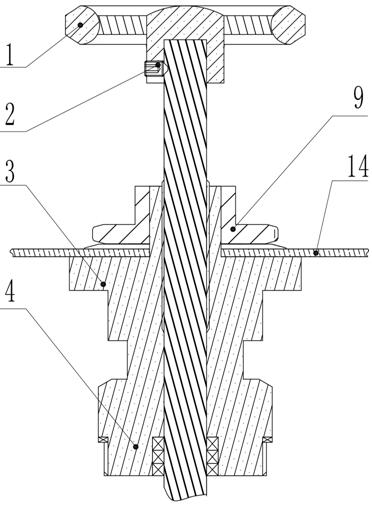

[0027] Such as figure 1 , figure 2 A panel type angle stop valve for an oxygen chamber as shown in the present invention includes a valve body 5, a gasket 1 7, and a valve stem 6; The air inlet 15, the air outlet 16 and the valve hole 17; the valve hole 17 is arranged directly above the air outlet 16; the ends of the air inlet 15 and the air outlet 16 are respectively detachably connected with a pipeline 13; Gasket one 7 is arranged in the valve body 5 corresponding to the air outlet 16 (located directly above the air outlet 16); the upper end of the valve rod 6 is arranged outside the valve body 5, and the lower end extends into the valve body 5 through the valve hole 17 and seals Gasket 7 is detachably connected and can move axially in the valve body 5 (while the valve stem 6 moves axially) to push the gasket 7 to block the air outlet 16 or pull the gasket 7 away from the air outlet 16; The upper end of the rod 6 is detachably connected with a hand wheel 1, so that the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com