Power station boiler air pre-heater anti-blocking device

A technology for power station boilers and air preheaters, applied in combustion methods, indirect carbon dioxide emission reduction, heat exchange equipment, etc., can solve problems such as large amount of engineering transformation, and achieve the effects of small transformation investment, high feasibility and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

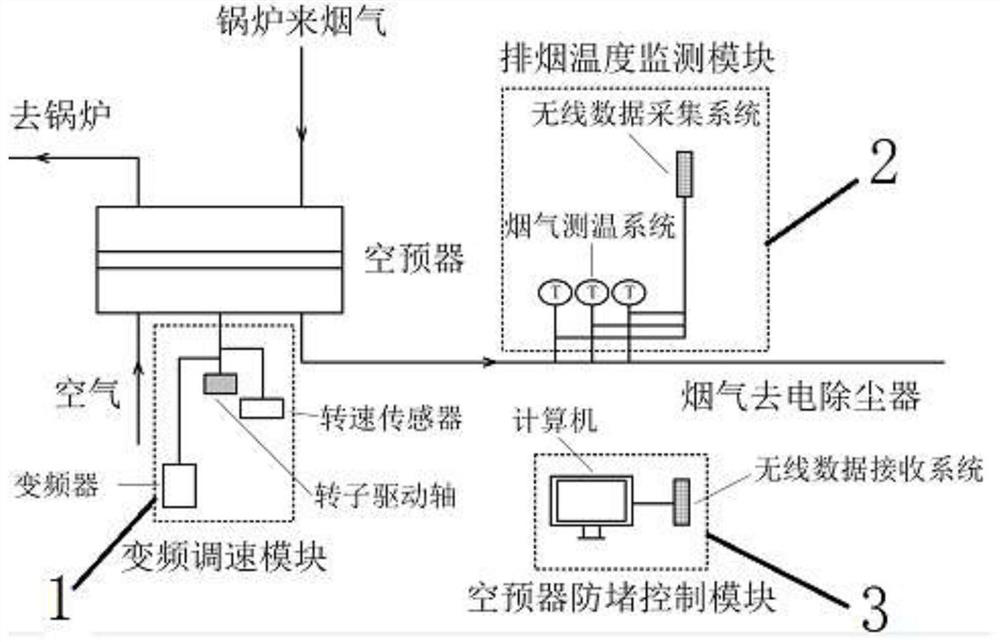

[0016] The present invention is a power plant boiler air preheater anti-blocking device, such as figure 1 As shown, it includes the air preheater, the air preheater is connected with the frequency conversion speed regulation module 1, the air preheater is equipped with the exhaust gas temperature monitoring module 2, the frequency conversion speed regulation module 1 is connected with the anti-blocking control module 3, and the anti-blocking control module 3 Connect the exhaust gas temperature monitoring module 2.

[0017] The frequency conversion speed regulation module 1 includes a rotor drive shaft, a frequency converter and a speed sensor are connected to the rotor drive shaft, and both the frequency converter and the speed sensor are connected to the anti-blocking control module 3 .

[0018] The exhaust gas temperature monitoring module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com