Biomass particle combustion furnace

A biomass particle and combustion furnace technology, which is applied in household stoves/stoves, solid heating fuel, lighting and heating equipment, etc., can solve the problem of not being able to reduce the slag of biomass particles, and achieve the effect of the best utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

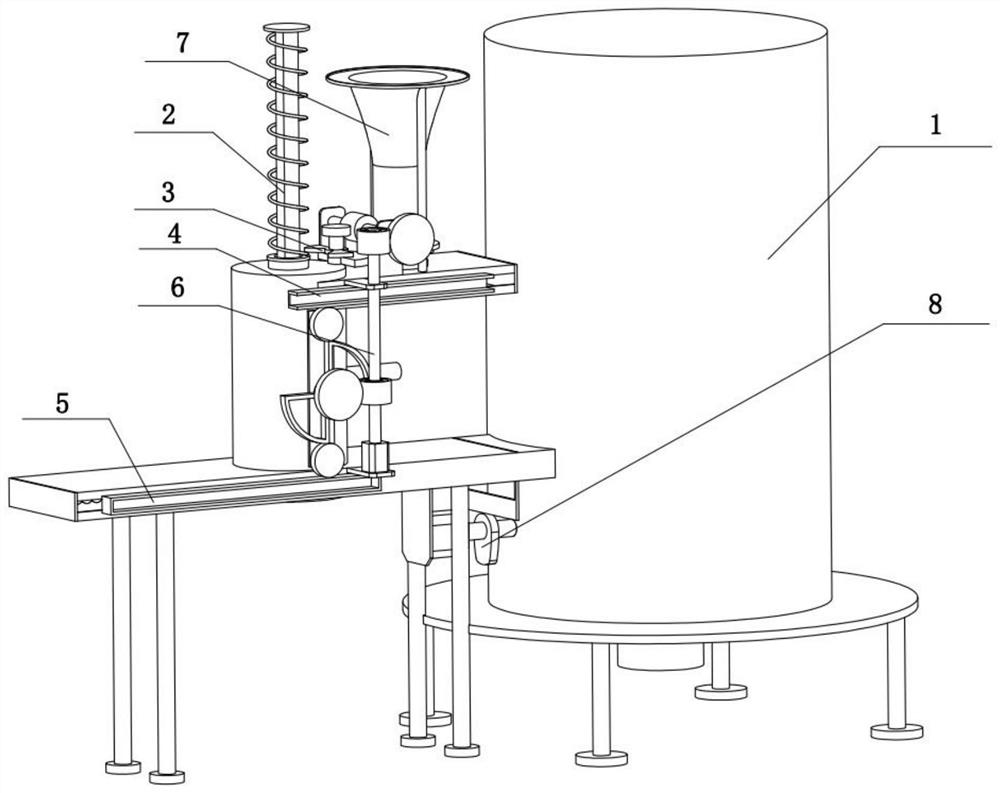

[0032]Bonded belowFigure 1-10In the present embodiment, the biomass particle combustion furnace includes a housing assembly 1, a compression assembly 2, a transmission assembly 3, a feed assembly 4, a discharge assembly 5, a drive assembly 6, a carrier assembly 7, and a feed combustion assembly 8. The compression assembly 2 is slidably coupled to the housing assembly 1, and the transmission assembly 3 rotates on the housing assembly 1, the compression assembly 2 and the transmission assembly 3 mesh the transmission, the feed assembly 4 slides on the housing assembly 1, out The material assembly 5 is slidably connected to the lower end of the housing assembly 1, and the drive assembly 6 is fixed to the housing assembly 1, the transmission assembly 3 and the drive assembly 6 mesh the transmission, the feed assembly 4 and the discharge assembly 5 mesh with the drive assembly 6. The carrier assembly 7 is fixed to the housing assembly 1, the carrier assembly 7 and the drive assembly 6 me...

specific Embodiment approach 2

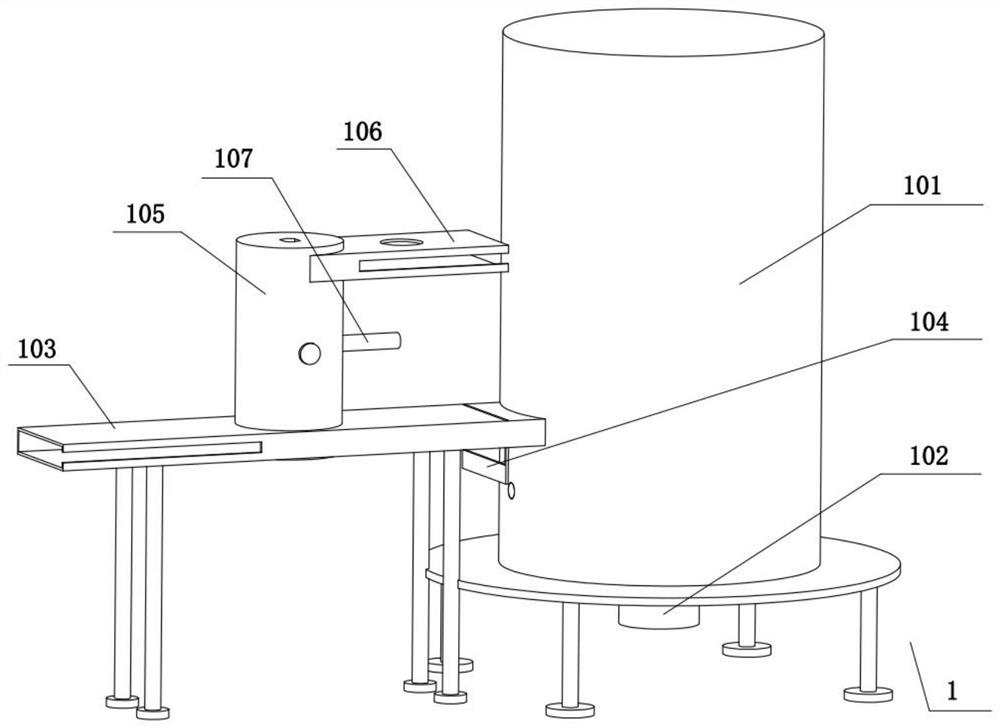

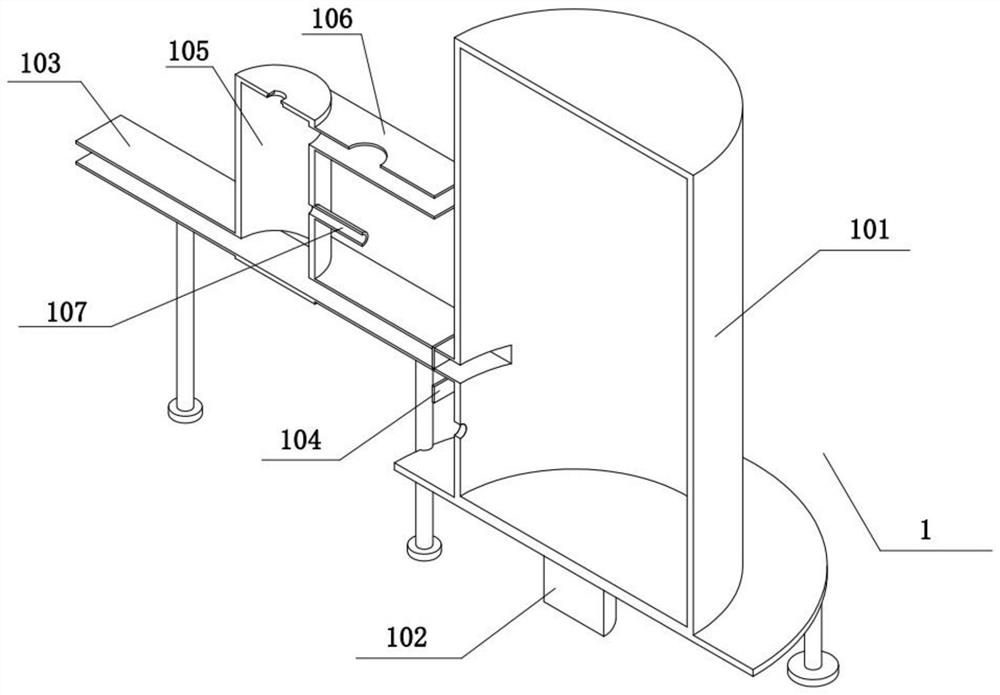

[0035]Bonded belowFigure 1-10In the present embodiment, the housing assembly 1 includes a combustion furnace 101, a ignition mechanism 102, a lower slide 103, a feed baffle 104, a shaped bucket 105, a bundle 106, and a connecting tube 107, and a lower end fixed connection of the combustion furnace 101. There is a ignition mechanism 102, and the lower slide 103 is fixed to the combustion furnace 101, and the add baffle 104 slides on the lower sliding track 103, and the shaped bucket 105 is fixed to the lower slide 103, and the upper slide 106 is fixed to the shaped bucket 105 The upper end is fixed to the connection tube 107 on the molded bucket 105.

specific Embodiment approach 3

[0037]Bonded belowFigure 1-10In the present embodiment, the compression assembly 2 includes a pressure type plate 201, a waist-type threaded rod 202, a threaded pipe gear 203, a spring plate 204, and a reset spring 205, and the shaped plate 201 is slidably connected to the molded bucket 105, a pressure type plate Fixed lumbar thread rod 202, the threaded pipe gear 203 is rotated on the shaped bucket 105, and the lumbar threaded rod 202 and the threaded pipe gear 203 are rotated by the threaded drive, and the spring plate 204 rotates on the threaded pipe gear 203, waist The upper end of the thread rod 202 and the spring plate 204 are fixed to the reset spring 205.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com