Micro-LED test circuit, device and method

A technology for testing circuits and testing electrodes, which is applied in the directions of measuring devices, circuits, measuring electricity, etc., can solve the problems of low efficiency of wafer LED testing and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

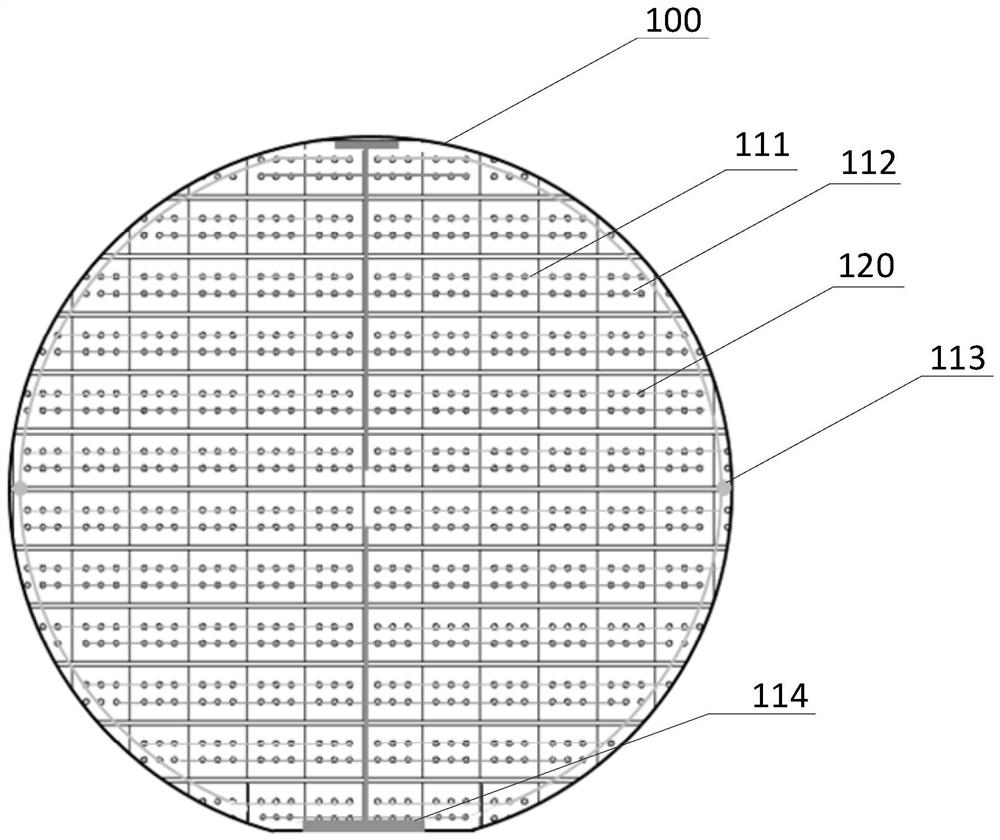

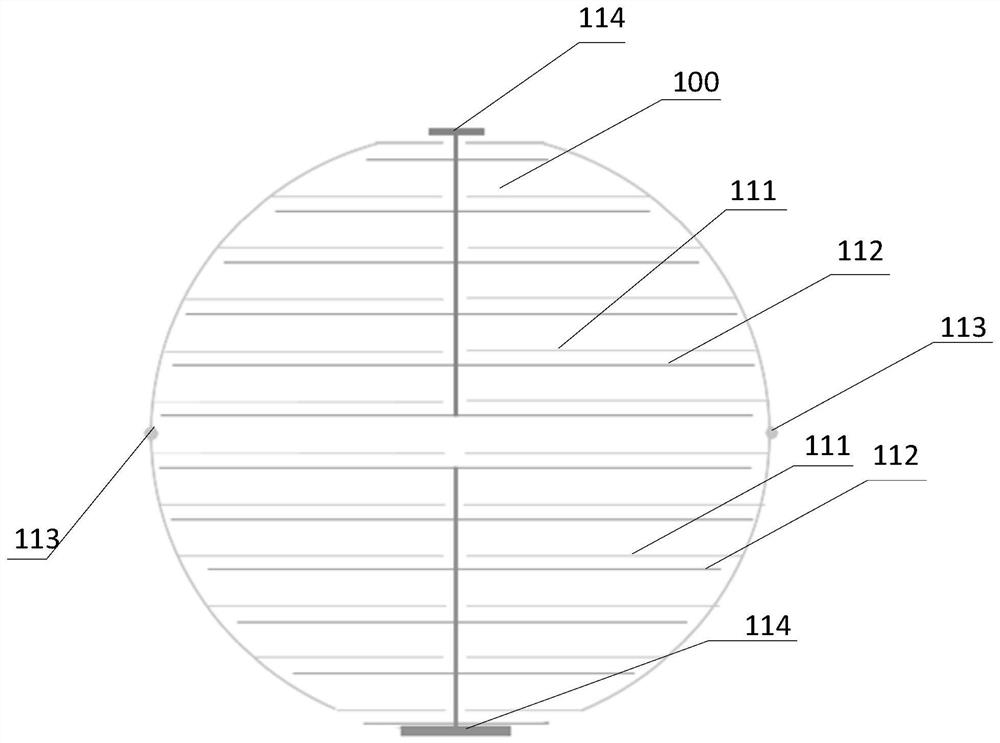

[0051] figure 1 It is a structural schematic diagram of an implementation mode of the Micro-LED test circuit in the embodiment of the present invention. Such as figure 1 As shown, the present embodiment provides a test circuit 100, including a first metal lead 111, a second metal lead 112, a first test electrode 113 and a second test electrode 114; the first metal lead 111 and the LED 120 of the wafer The anode is connected and extends to the outside of the epitaxial wafer or the light-emitting area of the wafer; the second metal lead 112 is connected to the cathode of the LED 120 of the wafer, and extends to the outside of the epitaxial wafer or the light-emitting area of the wafer; the first test electrode 113 is located on the extension section of the first metal lead 111; the second test electrode 114 is located on the extension section of the second metal lead 112; when the first test electrode 113 and the second test electrode 114 are respectively electrically conne...

Embodiment 2

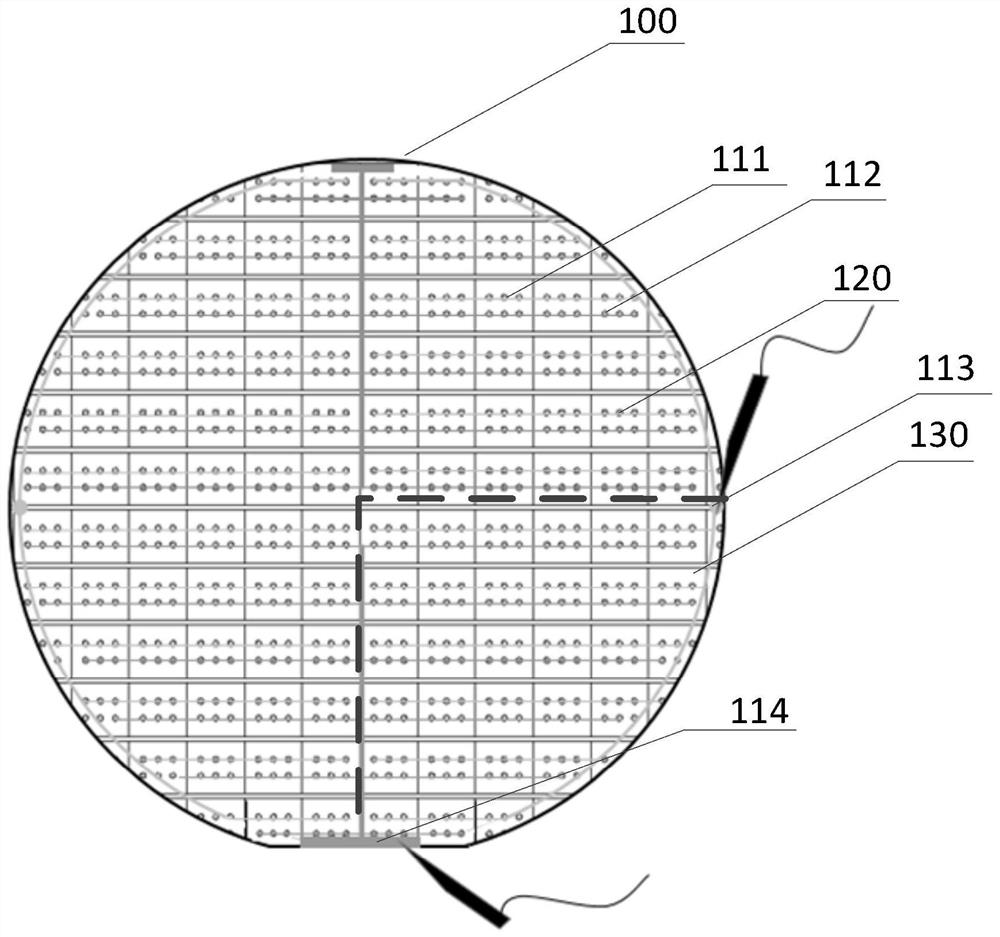

[0059] figure 2 It is a schematic structural diagram of another implementation of the Micro-LED test circuit in the embodiment of the present invention. Such as figure 2 As shown, the present embodiment provides a test circuit 100, including a first metal lead 111, a second metal lead 112, a first test electrode 113 and a second test electrode 114; the first metal lead 111 and the LED 120 of the wafer The anode is connected and extends to the outside of the epitaxial wafer or the light-emitting area of the wafer; the second metal lead 112 is connected to the cathode of the LED 120 of the wafer, and extends to the outside of the epitaxial wafer or the light-emitting area of the wafer; the first test electrode 113 is located on the extension section of the first metal lead 111; the second test electrode 114 is located on the extension section of the second metal lead 112; the first metal lead 111 and the second metal lead 112 divide the LED 120 of the wafer into two and ...

Embodiment 3

[0070] Figure 4 It is a structural schematic diagram of an implementation mode of the Micro-LED testing device in the embodiment of the present invention. Such as Figure 4 As shown, the present embodiment provides a test device 200, including: a stage 210, an image collector 220, a power supply 230, and a computer 240; The electrodes are contacted and connected to the second test electrodes, and are used to provide test signals to the LEDs of the wafer 250; the image collector 220 is used to collect test images corresponding to the wafer 250 during the test, and send the test images to the computer 240; the computer 240 A test result of the LEDs of the wafer 250 is obtained according to the test image.

[0071] In this embodiment, the wafer 250 has figure 1 , figure 2 In the shown test circuit, when testing, the wafer 250 is placed on the stage 210, and the probes connected to the power supply 230 or the test equipment are contacted with the first test electrode and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com