Graphite thermal expansion coefficient testing method capable of improving testing precision

A technology of thermal expansion coefficient and test method, applied in the direction of material thermal expansion coefficient, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as the influence of unresolved test results, and achieve the effect of avoiding adverse effects and uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

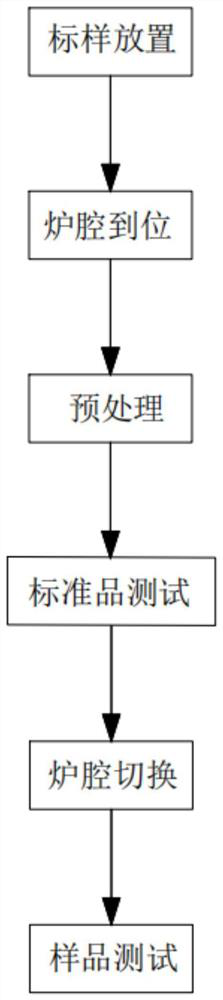

[0072] Such as figure 1 Shown, a kind of graphite thermal expansion coefficient test method that improves test precision, comprises the following steps:

[0073] Step 1, place the standard sample, place the standard sample of known expansion coefficient in the test groove 414 of the sample bracket 413 in the measuring mechanism 4 of the tester;

[0074] Step 2, the furnace cavity is in place, and the resistance furnace 2 facing the sample-testing bracket 413 is driven by the sliding mechanism 3 installed at the bottom to move toward the sample-testing bracket 413, so that the sample-testing bracket 413 extends into the The inside of the furnace chamber 21 of the resistance furnace 2;

[0075] Step 3, pretreatment, after the sample bracket 413 is inserted into the inside of the furnace chamber 21 of the resistance furnace 2, the vacuuming process is carried out through the vacuum pumping hole 212 on the furnace chamber 21, and then through the vacuum pumping hole 212 on the fu...

Embodiment 2

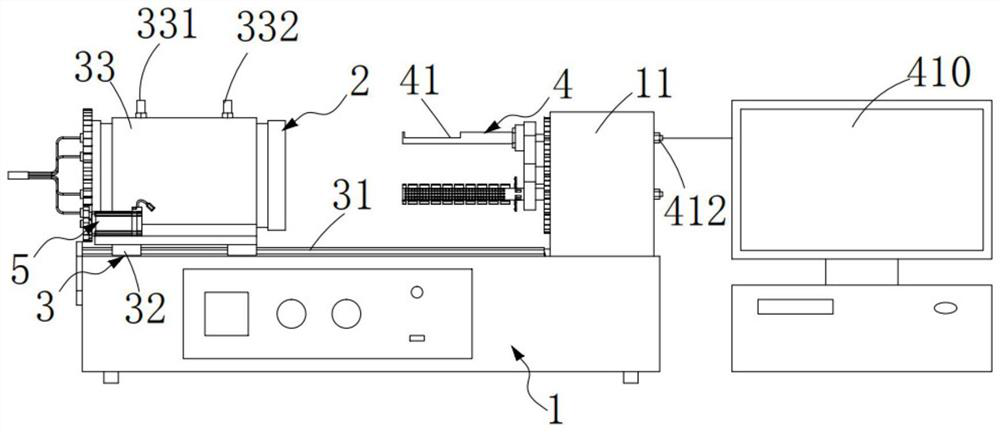

[0092] Such as Figure 2 to Figure 15 As shown, a high-efficiency graphite thermal expansion tester includes a horizontal box 1, and also includes:

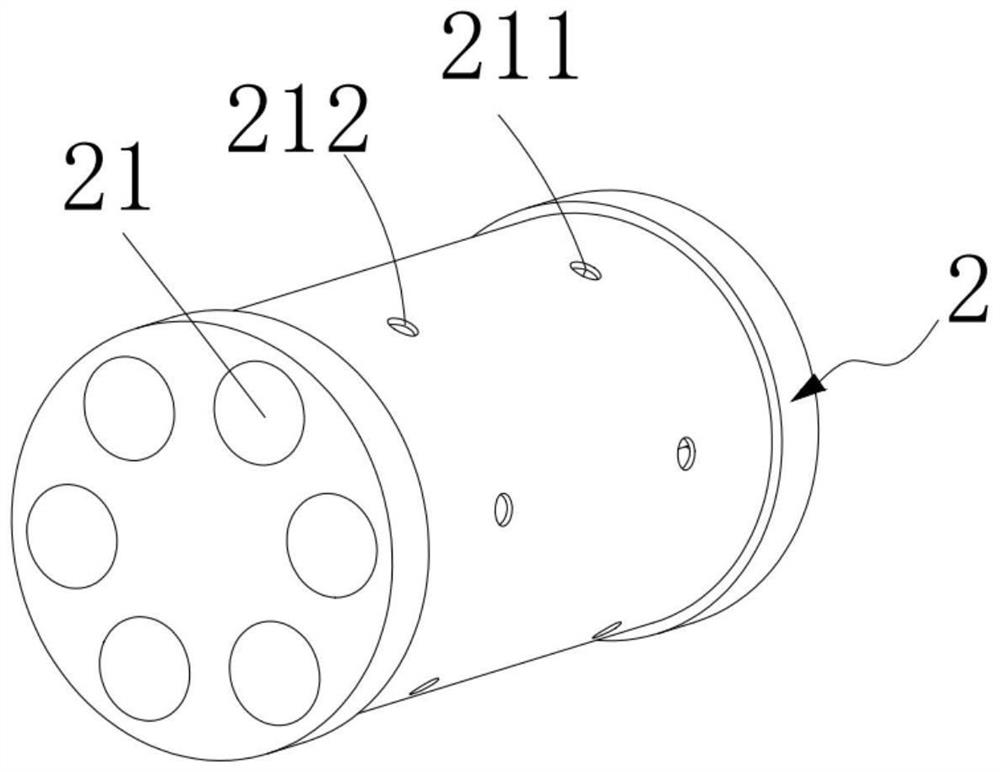

[0093] A resistance furnace 2, the resistance furnace 2 is slidably arranged on the horizontal box body 1 through a sliding mechanism 3, a number of furnace chambers 21 are arranged on the resistance furnace 2 in the axial direction, and the furnace chambers 21 are arranged in a circular equidistant manner On the resistance furnace 2, the resistance furnace 2 and the sliding mechanism 3 are relatively rotatable; and

[0094] Measuring mechanism 4, said measuring mechanism 4 is installed on said horizontal box body 1 facing said resistance furnace 2, said measuring mechanism 4 includes measuring assembly 41, said measuring assembly 41 includes transmission rod 411, length sensor 412 and The sample bracket 413, the transmission rod 411 is installed on the machine head 11 at the end of one side of the horizontal box body 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com