Charging control circuit, high-voltage control box and charging pile

A charging control and high-voltage control technology, applied in battery circuit devices, battery/fuel cell control devices, charging stations, etc., can solve the problems of cumbersome wiring, etc., and achieve the effect of overcoming cumbersome wiring, convenient wiring, and solving cumbersome wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

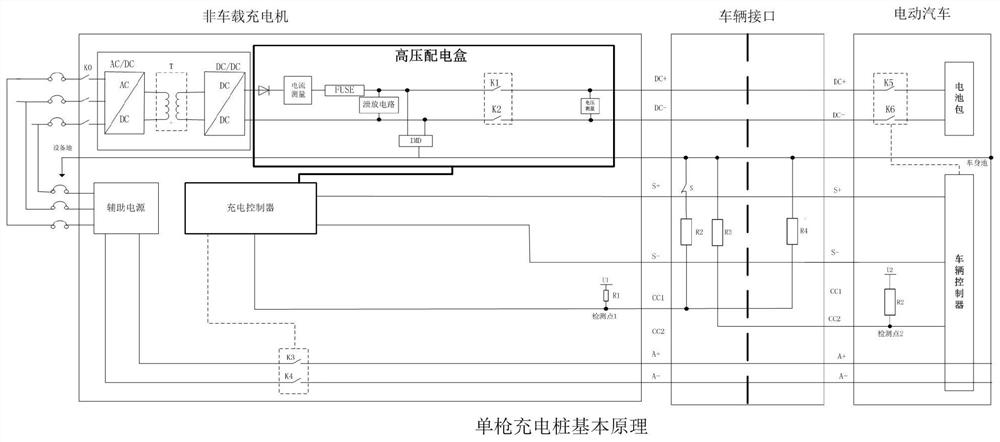

[0025]Such asfigure 2 As shown, the present embodiment is a charging control circuit of a single-played charging pile, and the charging control circuit includes a first charge circuit, a high pressure control circuit.

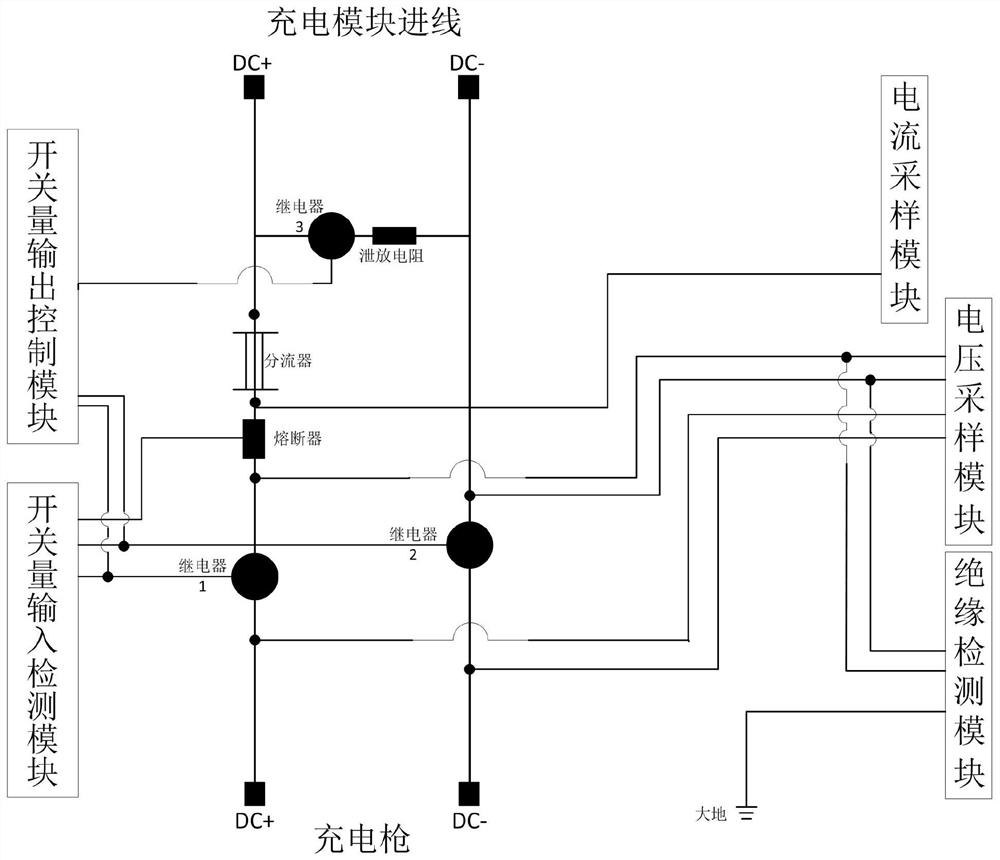

[0026]Preferably, the first charge circuit includes a first relay, a first fuse, a first substrate, a second relay, a first leakage circuit. The first leak circuit includes a third relay, a first leak resistor electrically connected to the third relay, and the connection of the first charge circuit uses the existing general standard connection mode.

[0027]Preferably, the high voltage control circuit includes: a master circuit, a master circuit integration, a master module chip. The high voltage control circuit also includes a turning-off state detection module, a relay control module, a current sampling module, a voltage sampling module, an insulating detection module, respectively, respectively, respectively.

[0028]Preferably, the first relay, the second relay, and the f...

Embodiment 2

[0039]Such asFigure 4As shown, the present embodiment is a charge control circuit for a double gun charging pile, and the charging control circuit of Example 2 includes a first charge circuit, a high pressure control circuit, wherein the difference between the first charging circuit is to connect the circuit connection. At different nodes, the location does not affect the normal operation of the first charging circuit, the high pressure control circuit is the same as the connection of the electronic components of the first charge circuit.

[0040]The second embodiment of the charging control circuit also includes a second charge circuit, and a high voltage relay for power allocation, a high voltage relay respectively disconnects a high voltage control circuit, and a relay control module is electrically connected.

[0041]Preferably, the second charge circuit includes a fourth relay, a second fuse, a second substister, a fifth relay, a second leakage circuit. The second leakage circuit inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com