PCB splitting machine

A technology of PCB circuit board and board splitting machine, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., to achieve the effect of improving cutting efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

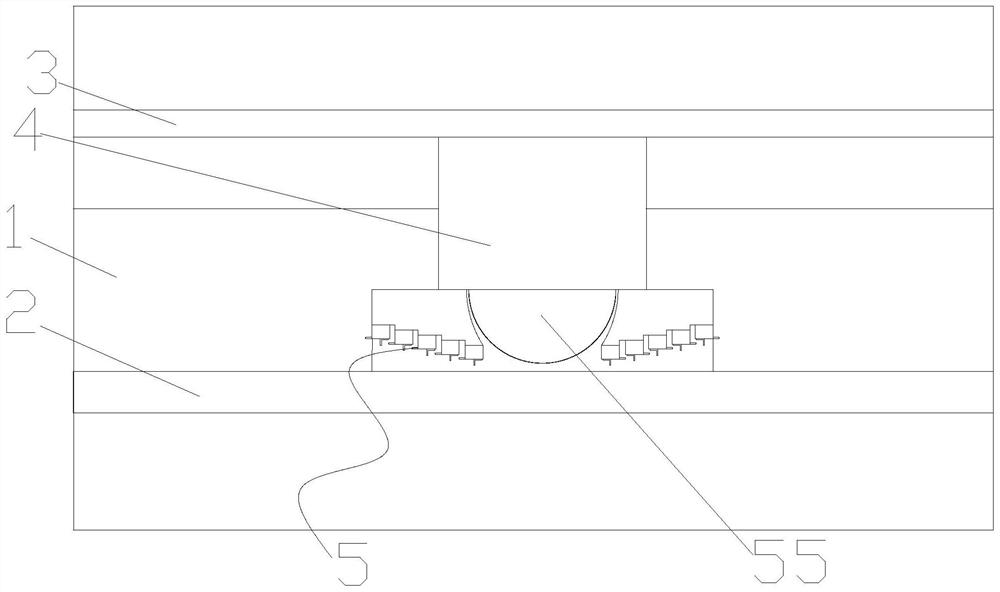

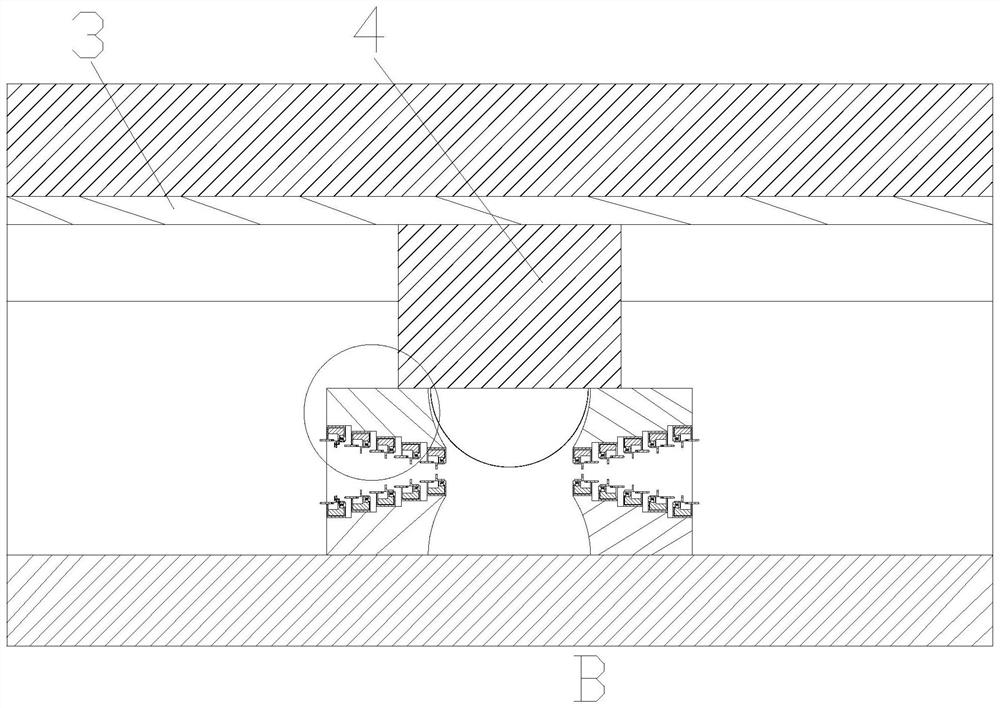

[0024] Attached below Figure 1-6 The present invention is further described with examples:

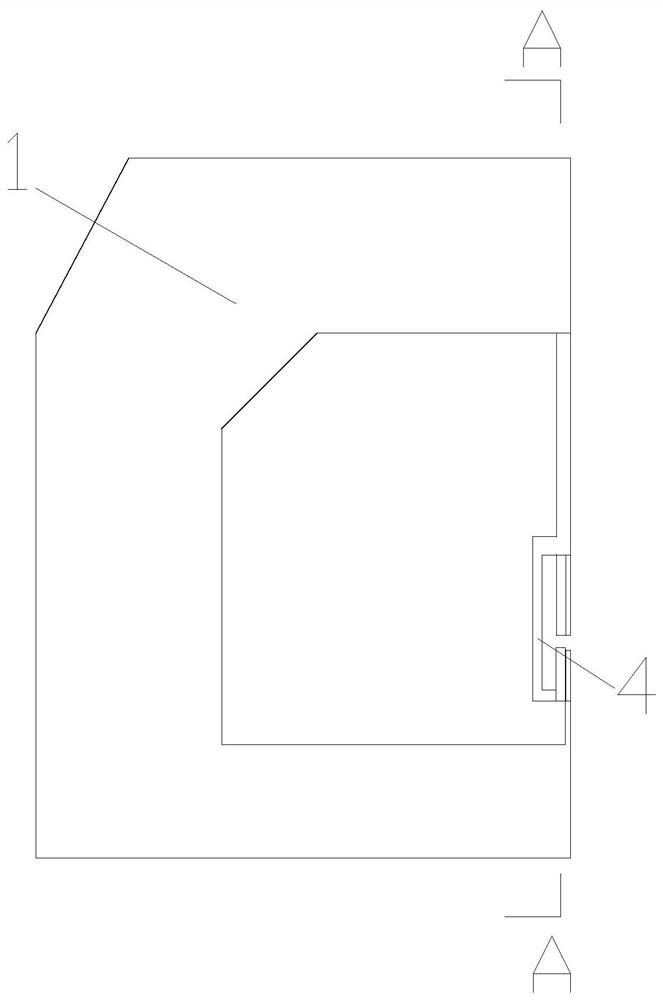

[0025] The PCB circuit board splitter includes a base 1, a lower blade 2 is fixedly arranged on the base 1, and an electric sliding rail 3 located above the lower blade 2 is fixedly arranged on the base 1. The electric sliding rail A fixed plate 4 is fixedly arranged on the movable end of 3, and a circular blade 55 is fixedly arranged on the fixed plate 4. It is characterized in that: the upper and lower sides of the fixed plate 4 are respectively provided with a positioning device 5.

[0026] The positioning device is two sets of positioning mechanisms arranged on both sides of the circular blade 55; The heights of the positions close to the circular blade 55 are sequentially lowered.

[0027] The positioning assembly 50 includes a support plate 601 fixed on the fixing plate 4 , a support plate 999 is fixedly disposed at the bottom of the support plate 601 , and an installation gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com