Stable strong-tension-resistant zipper

A zipper and stable technology, applied in the field of zippers, can solve problems such as easy cracking, zippers that cannot be closed, zippers that are not strong against pressure, etc., and achieve the effect of low production cost, strong stable structure, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Attached below Figure 1-7 To further illustrate the present invention, what is described is only a part of the embodiments of the present invention, and various changes, equivalent changes and modifications made by the skilled person to the present invention also fall within the scope of the claims of the present invention.

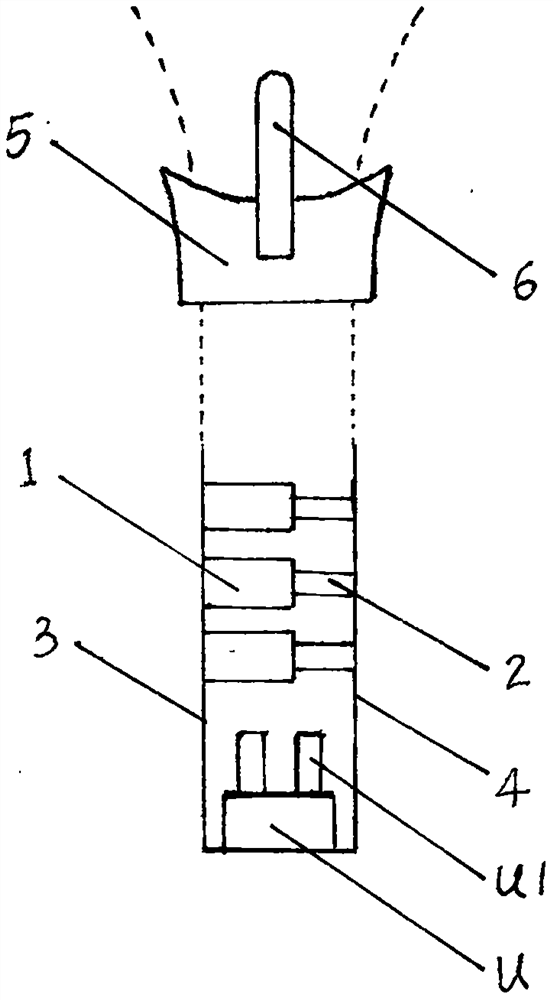

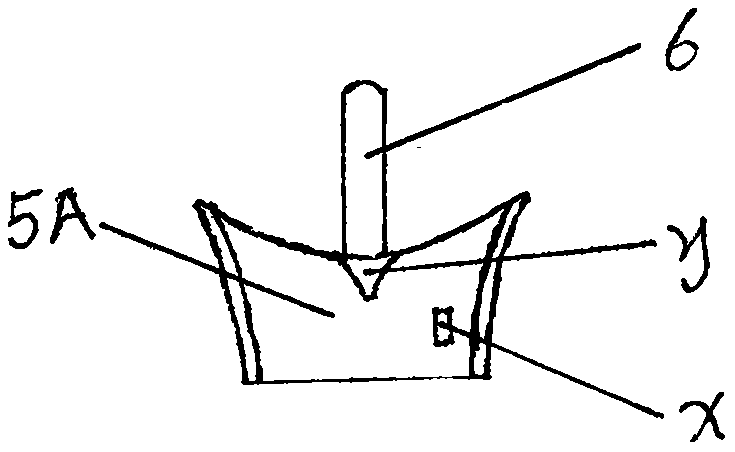

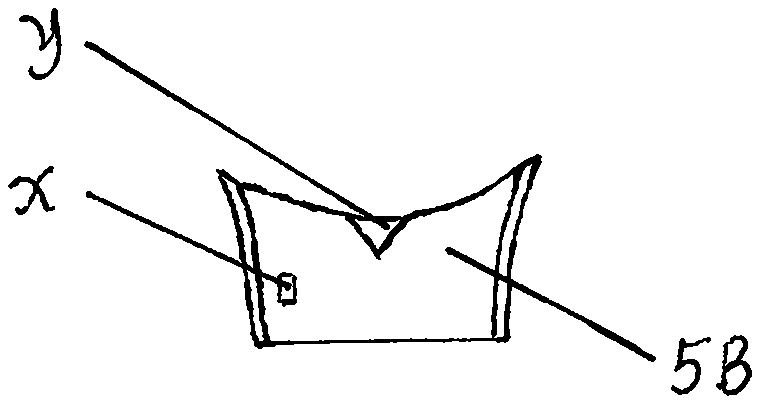

[0014] see figure 1 The socket U and inserting rod U1 are used in the same way as ordinary zippers. The pressing head 5 that is pulled up and down has a pull piece 6. The internal structure of the pressing head 5 is as follows: figure 2 It is the upper cover plate 5A of the pressing head, image 3 It is the lower cover plate 5B of the pressing head, figure 2 image 3 There are corresponding internal convex points X of the pressing head and connecting points Y of the upper and lower cover plates of the pressing head 5. The fabric piece is connected to the stable card box 1 on the left side of the zipper and the stable card plug 2 on the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com