Friction stir welding quality evaluation method, device and system based on clustering algorithm

A technology of friction stir welding and clustering algorithm, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of lack of real-time and efficient monitoring methods, high cycle cost, etc., to shorten the evaluation time and the number of required nodes, The effect of high accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

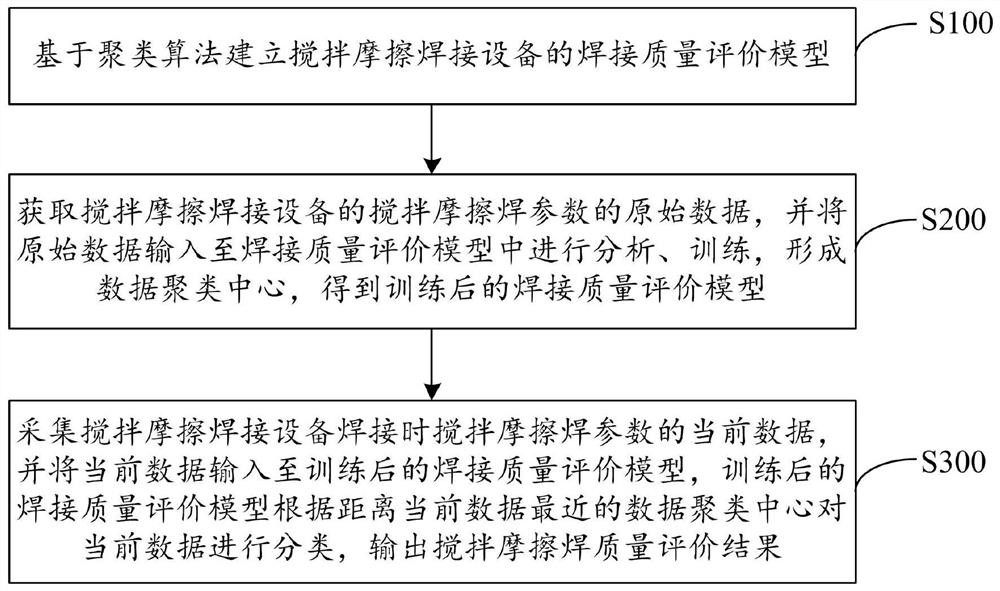

[0028] In one of the examples, as figure 1 As shown, the present invention provides a kind of friction stir welding quality evaluation method based on clustering algorithm, and this method comprises the following steps:

[0029] Step 1 (S100): Establish a welding quality evaluation model of friction stir welding equipment based on a clustering algorithm, wherein the clustering algorithm can be adopted but not limited to a self-organized incremental learning neural network or a K-means algorithm, etc., wherein the K-means algorithm can be Reduce the number of cluster centers to further improve the evaluation efficiency. With the continuous development of industrial big data technology, through the accumulation of a large amount of welding experience data, the use of self-organized incremental learning neural networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com