Tunnel monitoring equipment mounting trolley and using method thereof

A tunnel monitoring and equipment installation technology, applied in mining equipment, vehicle maintenance, mining equipment, etc., can solve problems such as difficulty in obtaining approval, difficulty in ensuring construction efficiency and safety, low accuracy and efficiency, etc., to achieve construction efficiency and The effect of security issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

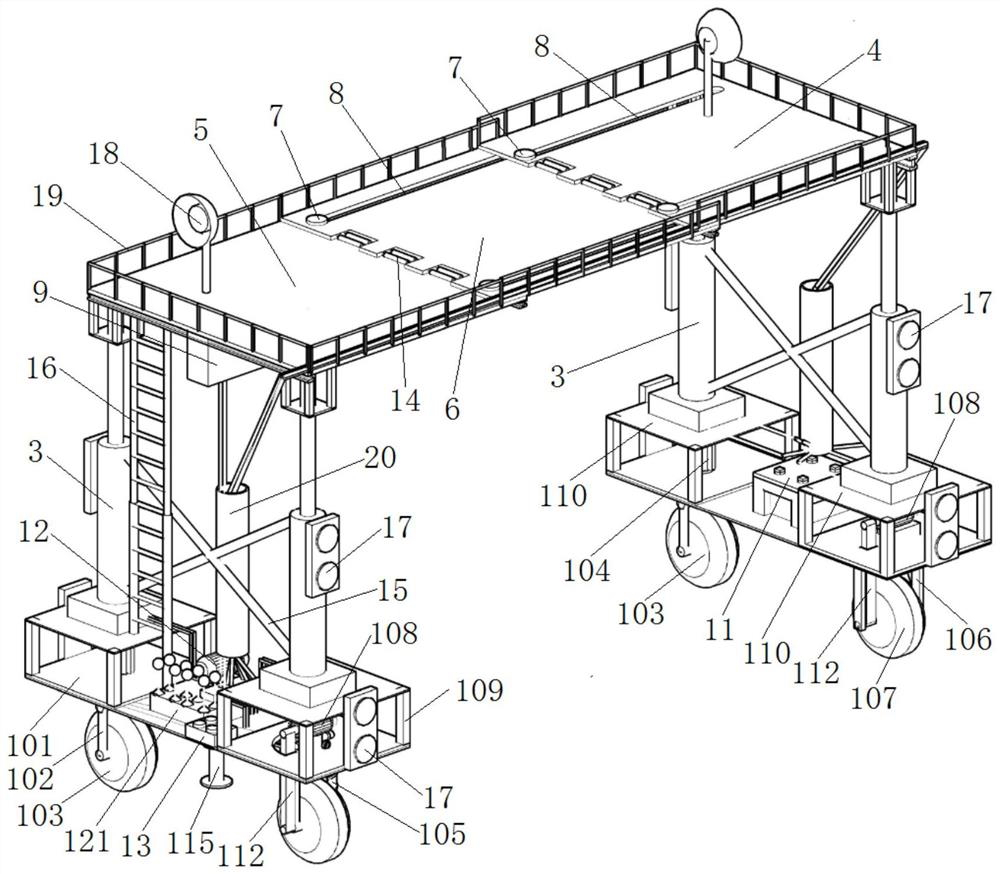

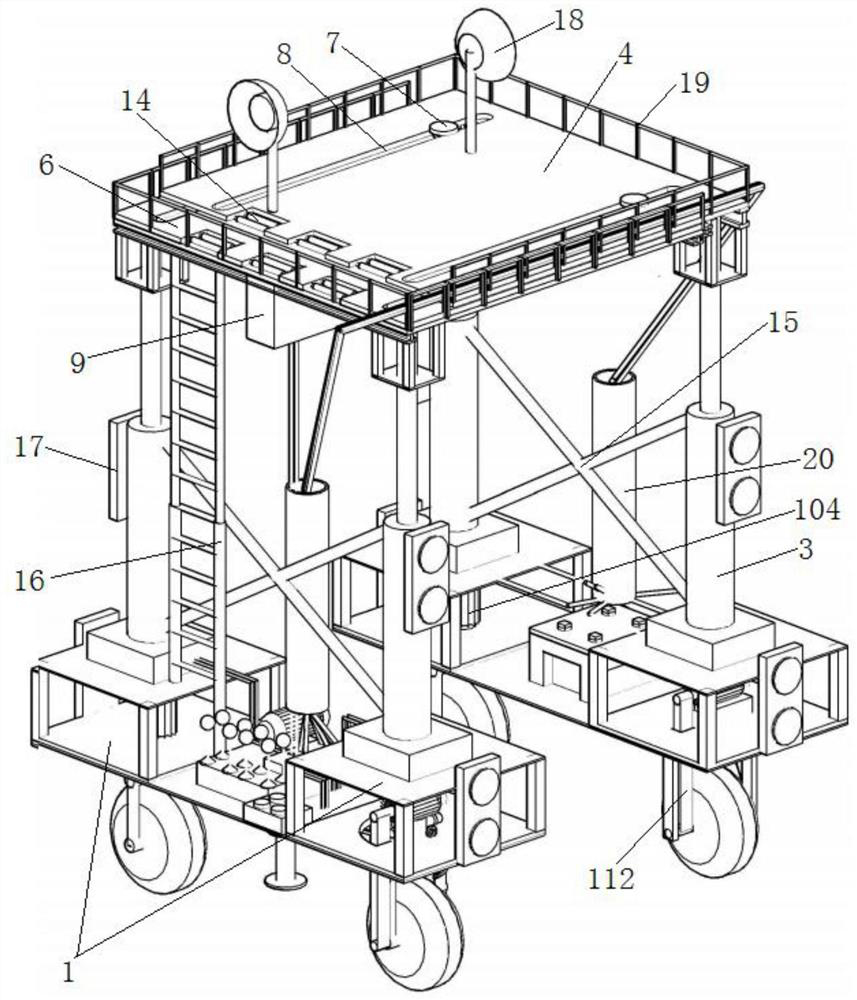

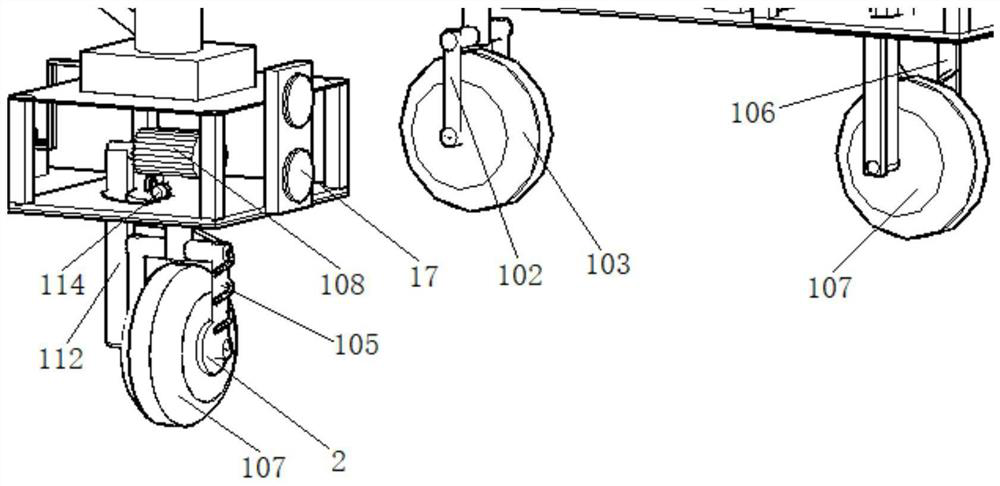

[0032] Such as Figures 1 to 5 As shown, the embodiment of the present invention provides a trolley for installing tunnel monitoring equipment, including a traveling mechanism. The traveling mechanism includes two traveling bases 1 arranged at intervals, and rollers are arranged on the lower side of the traveling base 1 . The upper side of the running mechanism is connected with a vertical telescopic mechanism, and the vertical telescopic mechanism includes four hydraulic cylinders 3 vertically arranged, and the four hydraulic cylinders 3 are fixed on the upper sides of the two walking b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com