Through channel with novel rapid tightening mechanism

A through-channel and fast technology, applied in railway car body parts, railway car body, transportation and packaging, etc., can solve the problems of time-consuming and labor-intensive, cumbersome operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

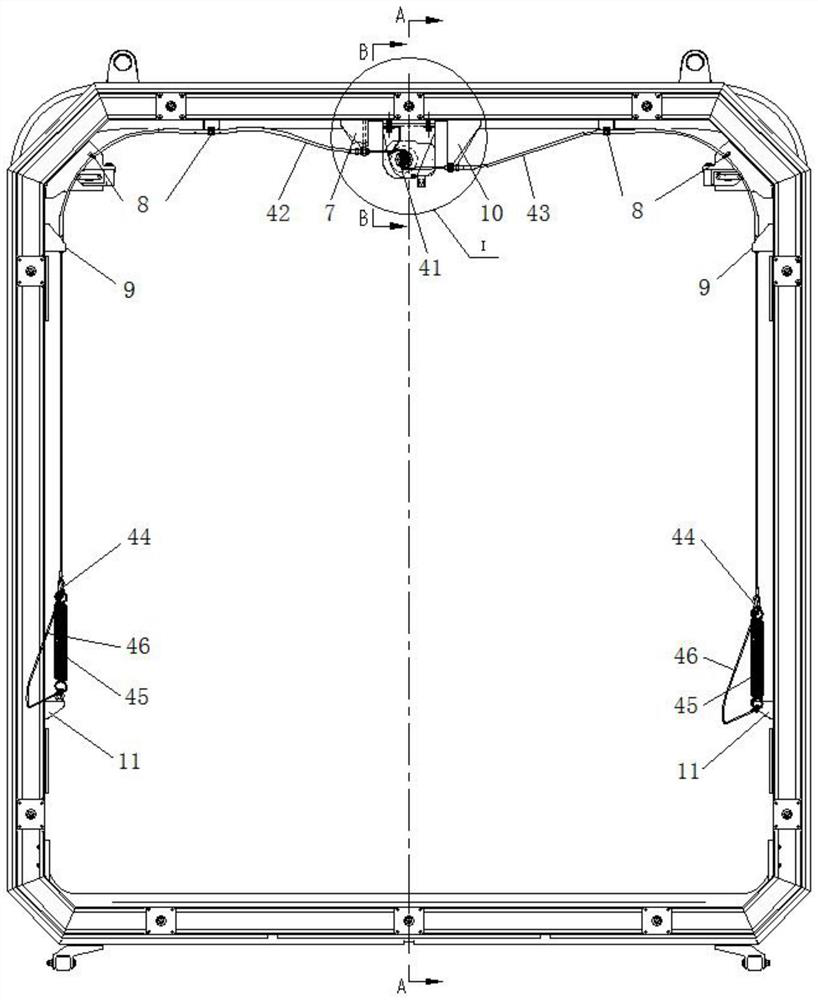

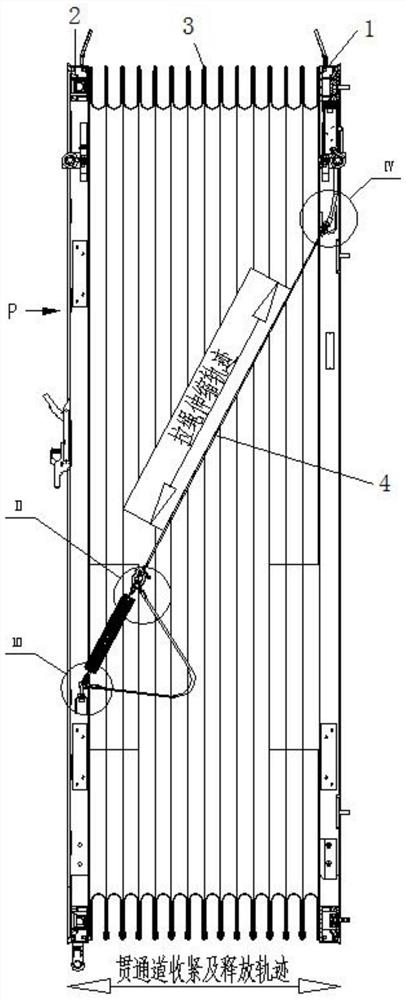

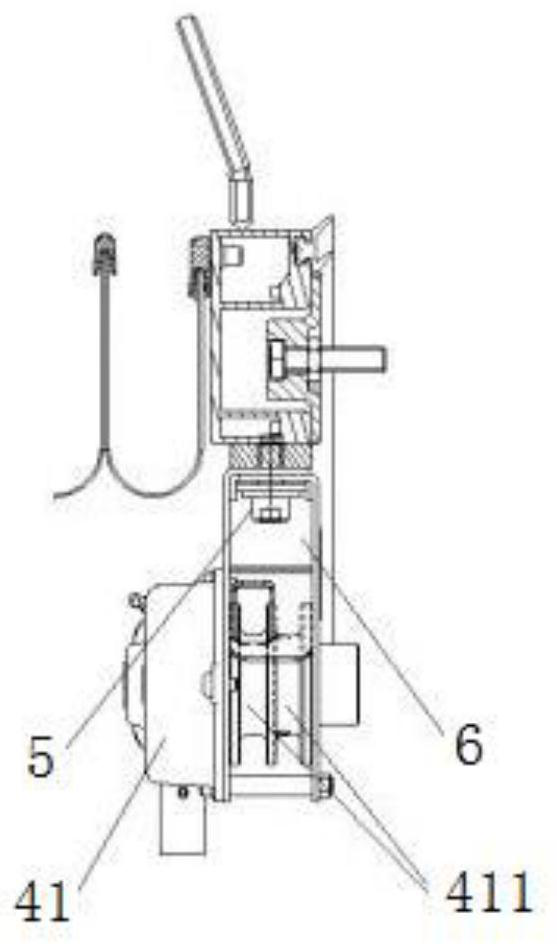

[0027] The main structure of the passageway with the novel fast tightening mechanism involved in this embodiment includes a fixed side frame body 1, a movable side frame body 2, a flexible body 3 and a tightening mechanism 4; the fixed side frame body 1 and the movable side frame body 2 A flexible body 3 is arranged between them, and the closed end of the tightening mechanism 4 of an inverted U-shaped structure is connected with the fixed side frame body 1, and the open end of the tightening mechanism 4 is connected with the movable side frame body 2; the main structure of the tightening mechanism 4 Include tightener 41, left rope 42, right rope 43, clasp 44, damper 45 and limit rope 46; Tensioner 41 is connected with one end of left rope 42 and right rope 43 respectively, left rope 42 and right rope The other end of 43 is respectively connected with the snap ring 44, and the snap ring 44 is connected with the damper 45 and the limit rope 46; the tightener 41 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com