A coke oven positive pressure oven process

An oven process and oven technology, which is applied in coke ovens, coke oven heating, combustible gas heating coke ovens, etc., can solve the problems of the air volume not being automatically controlled, the degree of automation control lagging behind, and the number of days of ovens being too long , to achieve the effects of shortening the coke oven drying time, reducing energy consumption and improving the quality of the oven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] A coke oven positive pressure oven process, the coke oven oven process in which the pressure of the carbonization chamber is positive pressure, specifically comprises the following steps:

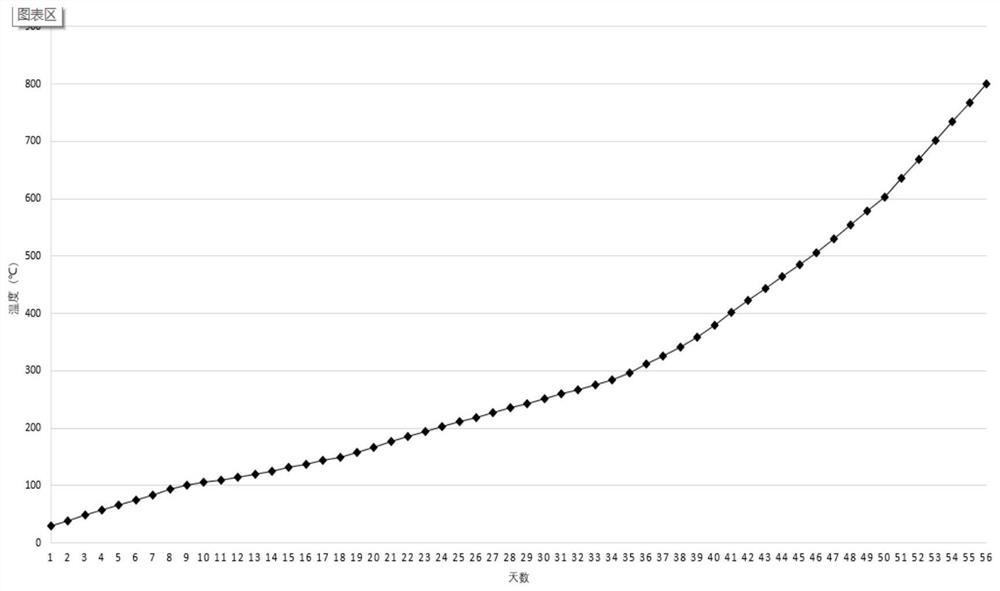

[0038] 1) As attached figure 1 As shown, after obtaining the coke oven silica brick sample expansion data, divide the expansion amount of the silica brick in each temperature range by the determined maximum daily expansion rate to calculate and determine the actual heating days, and use the maximum daily expansion rate of 0.04% to calculate the heating days It is 56 days, the abscissa is the number of heating days, and the ordinate is the temperature. Draw the coke oven heating curve, and prepare the oven plan according to the heating curve.

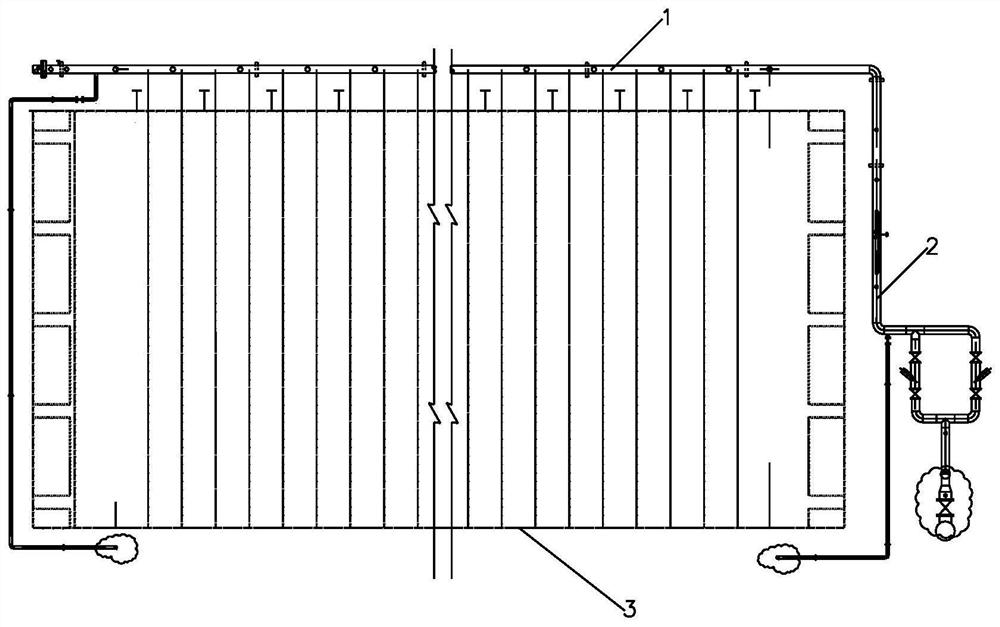

[0039] 2) if figure 2 As shown, when designing the oven pipeline drawing, one side of the coke oven is the coke side 1, and the other side is the machine side 3, and the oven pipeline 2 is arranged on the coke side 1 of the coke oven.

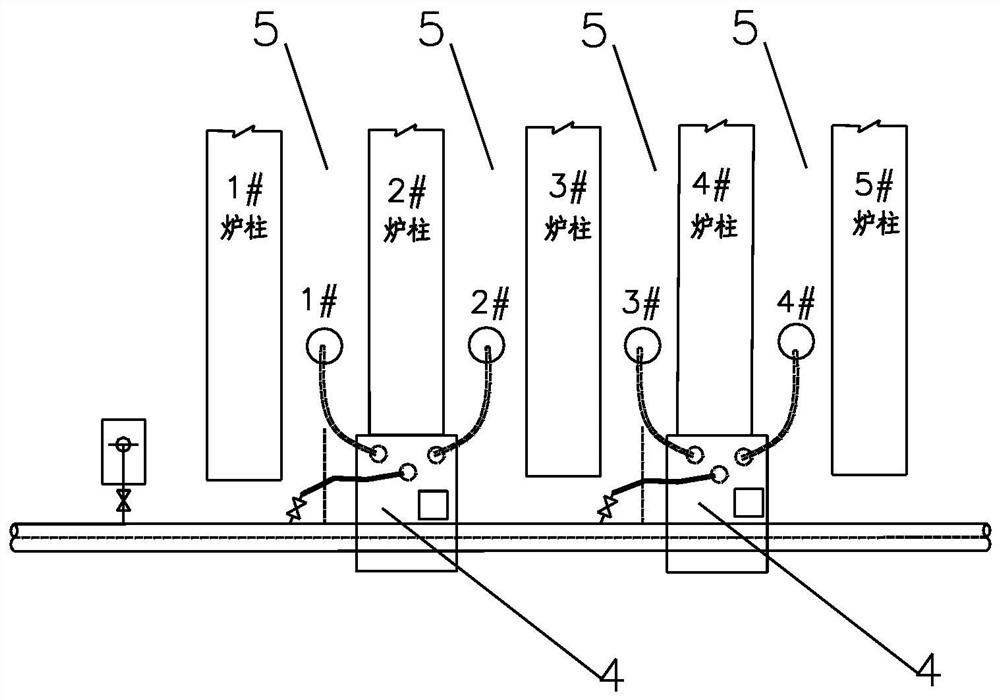

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com