Throttling control element based on memory alloy

A memory alloy, throttling control technology, applied in mechanical equipment and other directions, can solve the problems of stepper motor out of step, system oscillation, control logic confusion, etc., to achieve the effect of good reliability, high precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

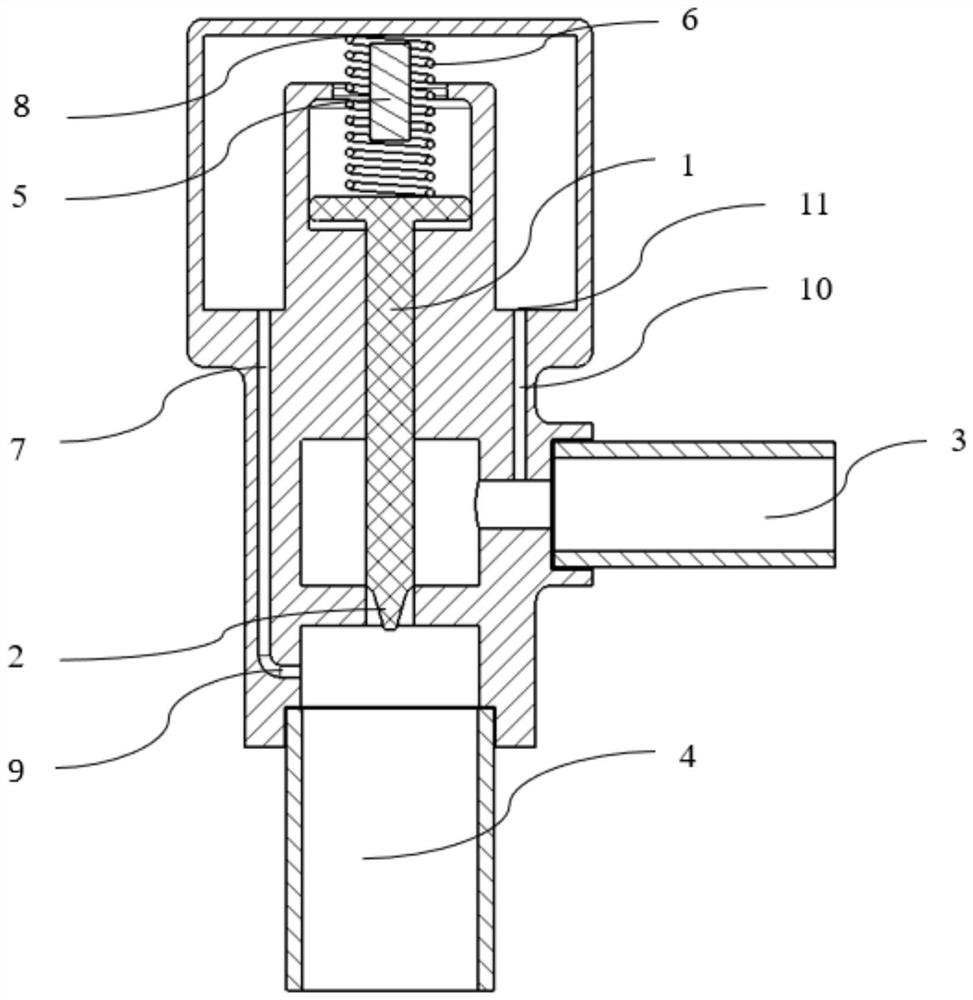

[0012] Such as figure 1 As shown, this embodiment includes: a valve stem 1, a shape memory alloy spring 6, a heating block 5 located in the shape memory alloy spring 6, refrigerant passages 7, 8 located in the casing, and refrigerant stop valves arranged at both ends thereof 9, 11, wherein: the inlet 3 of the housing is connected to the outlet of the condenser, the outlet 4 of the housing is connected to the inlet of the evaporator, one end of the shape memory alloy spring 6 is fixed on the inner surface of the upper cover 8 of the valve body, and the other end is fixed on the valve body On the upper surface of the rod 1, the refrigerant that cools the shape memory alloy spring 6 is adjusted through the high-pressure refrigerant stop valve 11 and the low-pressure refrigerant stop valve 9, and passes through the high-pressure refrigerant passage 10, the low-pressure refrigerant passage 7 and the inlet 3. The refrigerant circulates and flows out through outlet 4.

[0013] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com