Circular efficient drier for copper concentrate

A technology of copper concentrate and dryer, which is applied in the direction of dryer, drying, drying solid materials, etc., can solve the problems of skin burns, etc., and achieve the effects of avoiding burns, facilitating heat recovery, and convenient temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

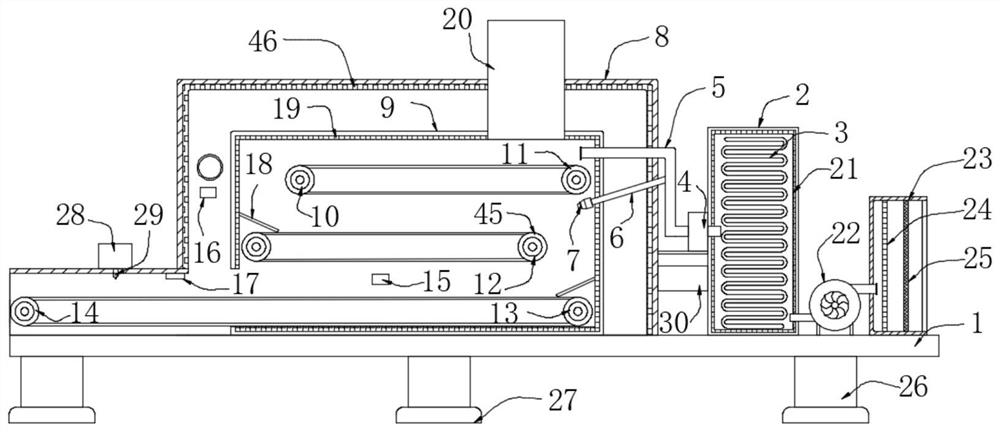

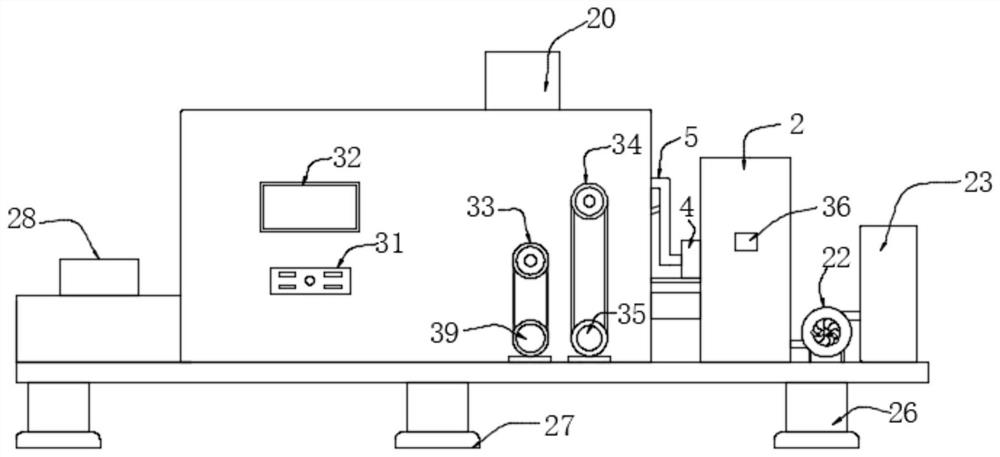

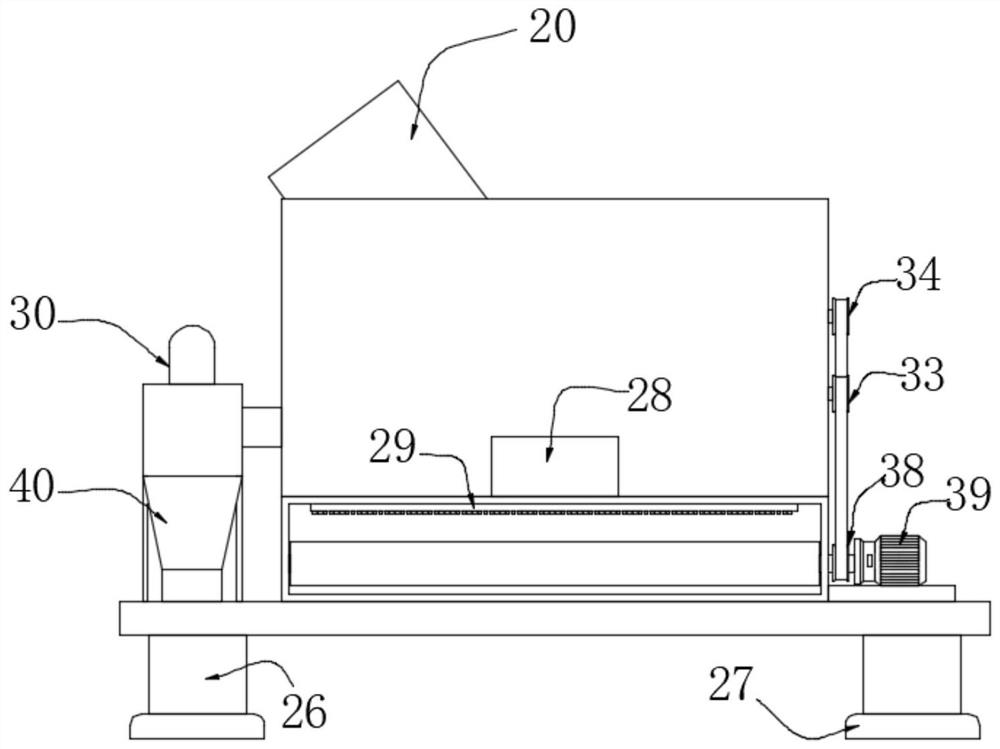

[0027] see Figure 1-4 , the present invention provides a technical solution: a high-efficiency circulating dryer for copper concentrate, comprising a first support plate 1, the upper surface of the first support plate 1 is fixedly connected with a first box body 2, and the first box body 2 The inner side wall of the first support plate 1 is equipped with a heating pipe 3, the upper surface of the first support plate 1 is equipped with a second exhaust fan 22, and the air outlet of the second exhaust fan 22 is connected to the inner side wall of the first box body 2, and the first box body 2 A first exhaust fan 4 is installed on one side, the air outlet of the first exhaust fan 4 communicates with the first pipe body 5, the air inlet of the first exhaust fan 4 communicates with the inner side wall of the first box body 2, and the first support plate 1 The upper surface of the first housing 8 is fixedly connected with the first housing 8, the inner wall of the first housing 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com