Bus chamber structure of high-voltage miniaturized air-insulated switch cabinet

An air-insulated, cabinet bus room technology, applied in switchgear, switchgear setting, substation/switch layout details, etc., can solve the problems of inconvenient insulation strength and mechanical strength, inconvenience for long-term safe use, and difficulty in normal use of circuits, etc. Achieve good mechanical properties and anti-aging properties, easy for long-term safe use, and not easy to short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

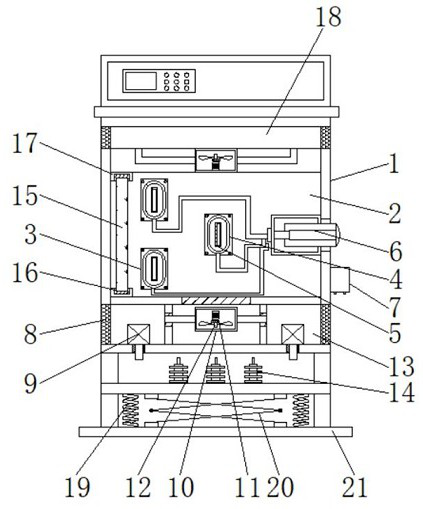

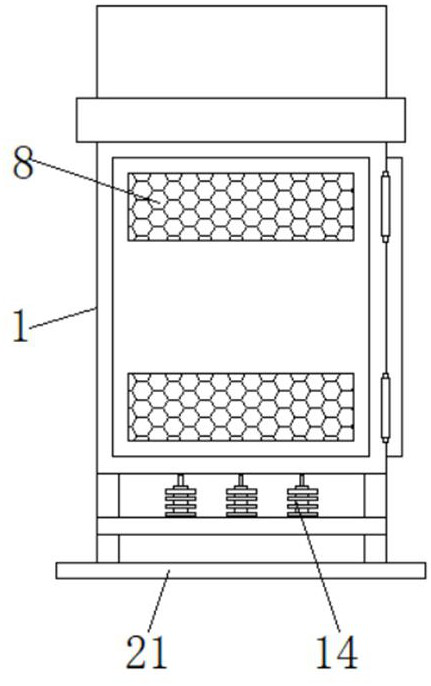

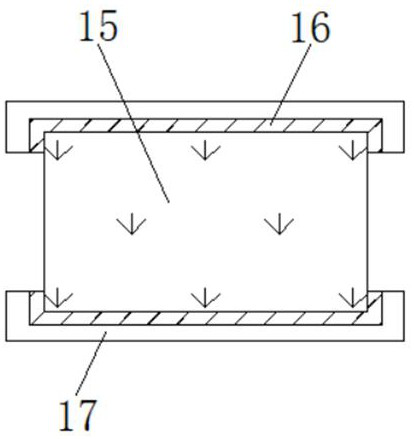

[0024]SeeFigure 1-5The present invention provides a technical solution: a high-pressure miniaturized air insulated switch cabinet shab chamber structure, including the body 1, the bus bar region 2, the mounting plate 3, the busbar sleeve 4, the main bus 5, the static contact head 6, current Incidental block 7, dust network 8, refrigeration block 9, bellow 10, bearing 11, air supply fan 12, cooling region 13, ground bus wire 14, moisture-proof plate 15, card slot 16, fixed block 17, pressure relief channel 18, spring 19 The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com