Nitrogen-doped porous carbon loaded metal cobalt material as well as preparation method and application thereof

A nitrogen-doped porous carbon and metal-loaded technology, which is applied in structural parts, secondary battery repair/maintenance, battery pack components, etc., can solve difficult electrochemical reaction processes and other problems, and achieve simple preparation process and capacity decay The effect of small rate and strong affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of nitrogen-doped porous carbon material: Take 100 mg of Ketjen Black (KJ-600) in a vial, absorb water vapor for 50 minutes in a water vapor atmosphere at 80 ° C, and then place KJ-600 in NH 3 The nitrogen-doped porous carbon material was obtained by reacting in a tube furnace with an air velocity of about 30 SCCM for 1 hour.

[0040] The obtained nitrogen-doped porous carbon material was immersed in a saturated cobalt acetylacetonate / ethyl acetate solution (1:10 by volume) for 8 h. The samples were then transferred to a glove box, filtered and dried, and placed in NH 3 Calcined at 800°C for 1 hour in a tube furnace with an air flow rate of about 50 SCCM to obtain a nitrogen-doped porous carbon-supported metal cobalt material, which is marked as Co-800@KJ.

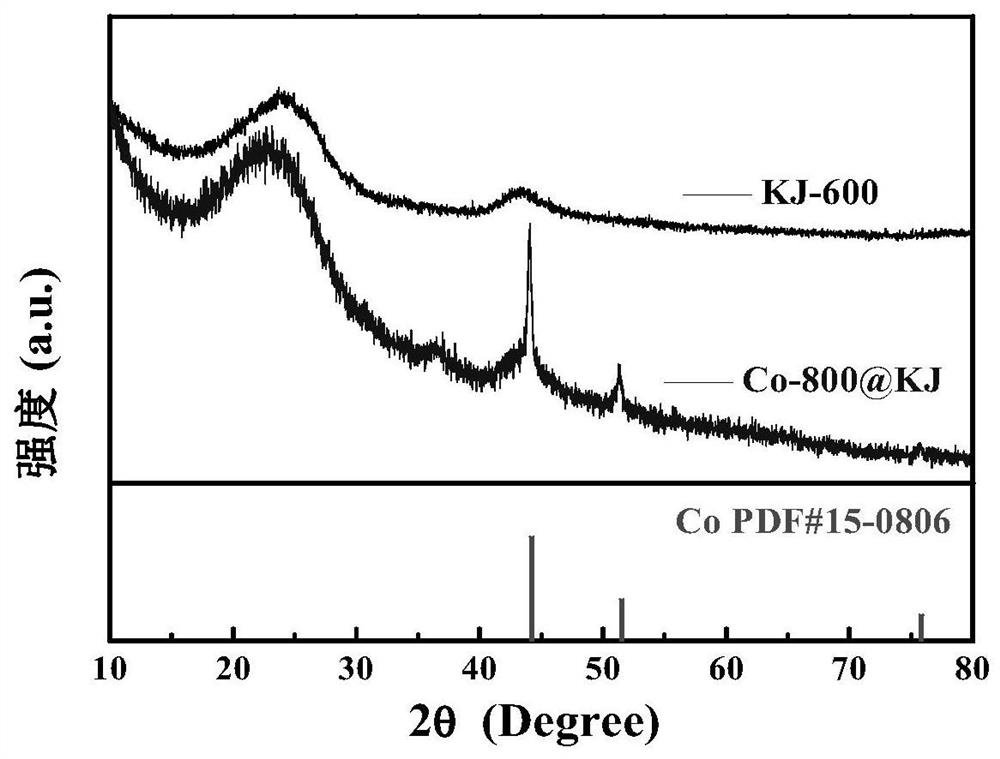

[0041] figure 1 It is the XRD spectrum of Co-800@KJ obtained in this example. It is replaced by two distinct diffraction peaks at 2θ=44.2° and 51.6°, which are consistent with (111) and (200) crystal ...

Embodiment 2

[0043]Mix 700mg of the nitrogen-doped porous carbon-supported metal cobalt material Co-800@KJ obtained in Example 1 with 300mg of sulfur and impregnate at 155°C for 10 hours, and then press the impregnated mixed material, super P and polyvinylidene fluoride according to The mass ratio is 8:1:1 mixed as the positive electrode material, assembled with lithium metal and Celgard2400 separator to form a lithium-sulfur battery, and tested, the active mass loading of all tests is 1-5mg cm -2 . KJ-600 is assembled into a lithium-sulfur battery using the same method.

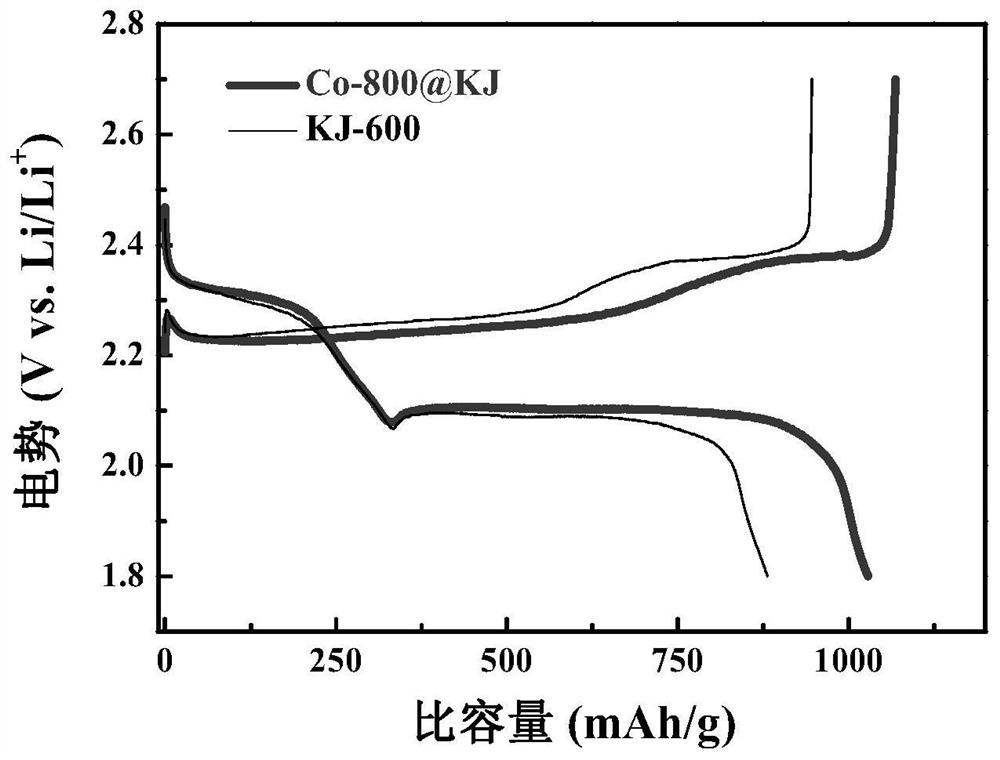

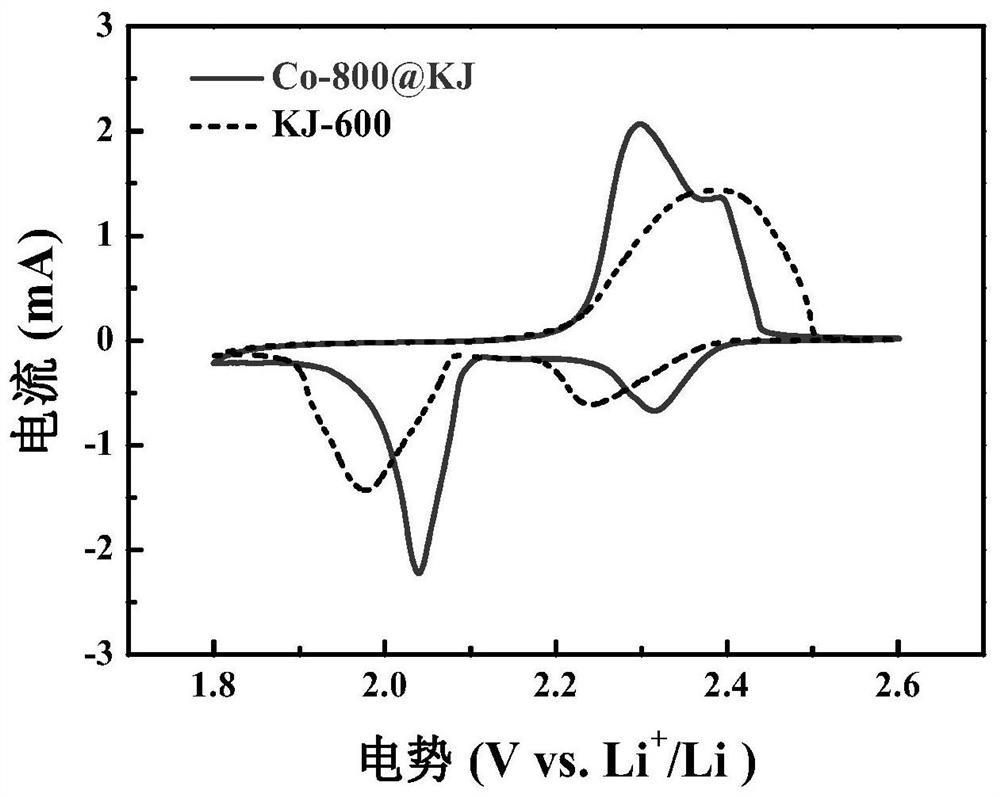

[0044] Figure 2a The charging and discharging diagram of the first cycle of the battery is the KJ-600 obtained in Example 2 used as the positive electrode carrier of the lithium-sulfur battery and Co-800@KJ used as the positive electrode carrier of the lithium-sulfur battery. Figure 2b The cyclic voltammetry curves of KJ-600 obtained in Example 2 as the positive electrode carrier for lithium-sulfur batteries and Co-8...

Embodiment 3

[0046] Grind the nitrogen-doped porous carbon-supported metal cobalt material Co-800@KJ and polyvinylidene fluoride (binder) in Example 1 in a mortar at a mass ratio of 6:4, and add an appropriate amount of nitrogen methyl The homogeneous slurry obtained after pyrrolidone (NMP) is coated on one side of the Celgard2400 diaphragm, dried, cut into 19mm discs, and used as the diaphragm of the battery, wherein the material faces the positive electrode, and the preparation of the positive electrode material is the simplest. The original method is to directly mix pure sulfur with a binder, coat it on aluminum foil, and dry the cut piece as a pole piece. KJ-600 uses the same method to coat the separator and assemble it into a lithium-sulfur battery.

[0047] image 3 , Figure 4 The AC impedance (Nyquist) curves of the lithium-sulfur battery with KJ-600 obtained in Example 3 as the diaphragm modification material and Co-800@KJ as the diaphragm modification material and the nitrogen-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com