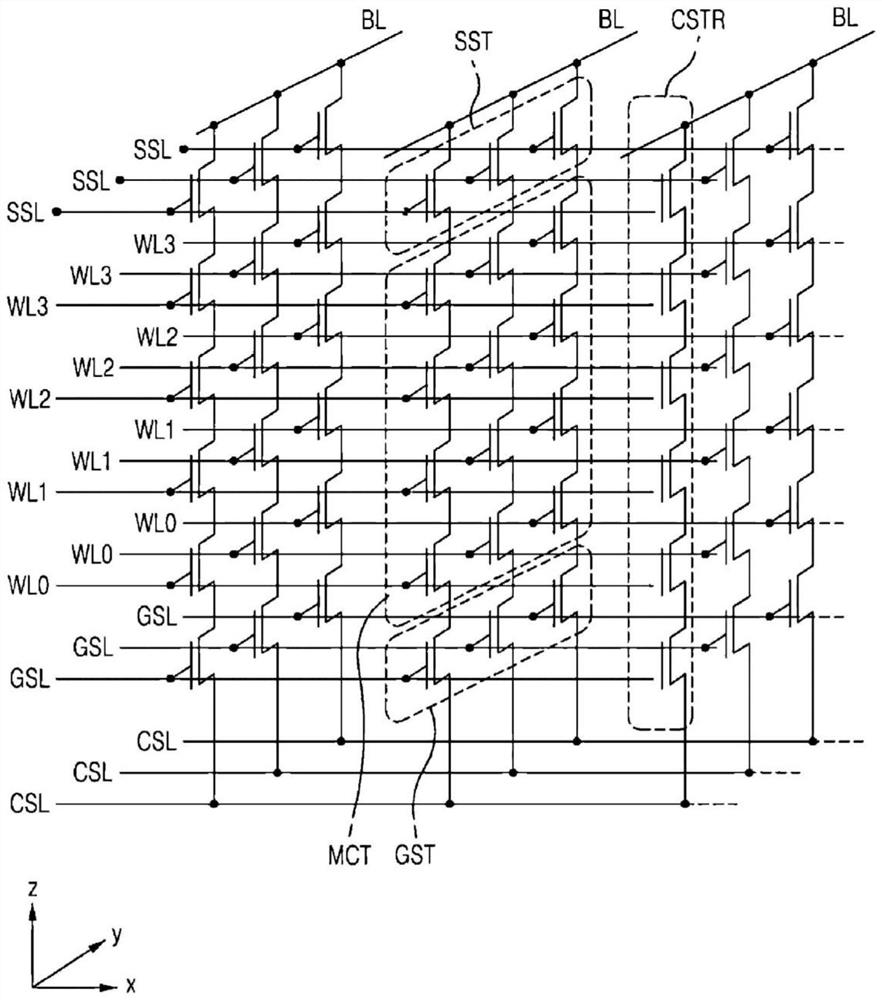

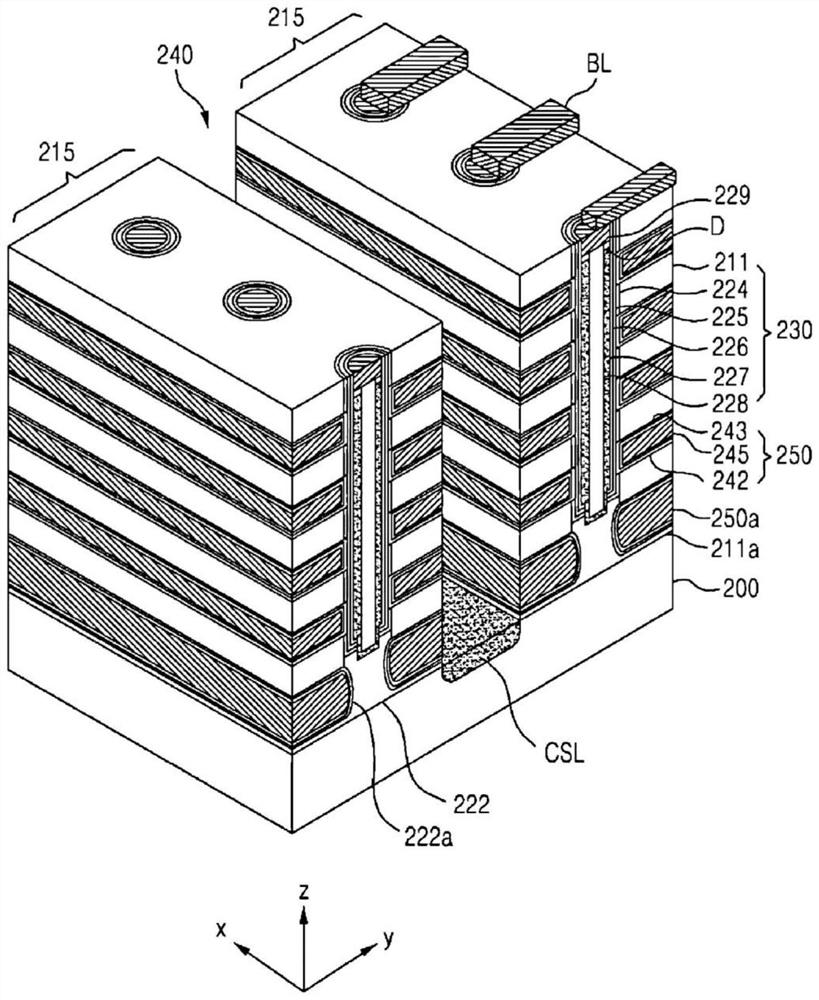

Three-dimensional flash memory including intermediate wiring layer, and manufacturing method therefor

A flash memory, three-dimensional technology, applied in static memory, read-only memory, semiconductor/solid-state device manufacturing, etc., can solve the problems of high process cost and material degradation, and achieve simplified wiring process, improved integration, and reduced unit The effect of deterioration of characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Hereinafter, embodiments will be described in detail with reference to the accompanying drawings. However, the present invention is not limited or restricted by the examples. In addition, the same reference numerals shown in each drawing designate the same elements.

[0091] In addition, terms used herein may be terms for appropriately expressing preferred embodiments of the present invention, and may be changed based on user's or operator's intention or custom of those of ordinary skill in the art. Therefore, definitions of terms must be determined based on the contents described in the specification.

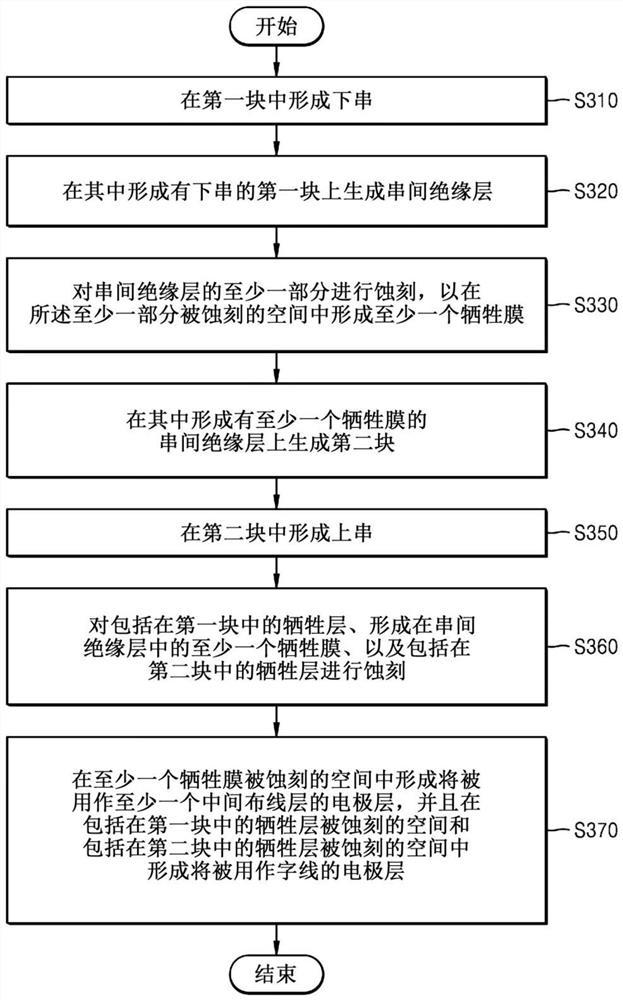

[0092] image 3 is a flowchart illustrating a method of manufacturing a three-dimensional flash memory according to an embodiment, Figure 4A to Figure 4J is shown for description image 3 A diagram of a first embodiment of a method of fabricating a three-dimensional flash memory is shown. Hereinafter, it is assumed that the method of manufacturing a three-dimensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com